In a study published in the journal Burns & Trauma, researchers from Shanghai Jiao Tong University and Donghua University developed a new type of vascular graft using 3D printing and electrospinning. This graft has the potential to reduce blood clot formation and prevent aneurysms after surgery, which could improve outcomes for cardiovascular disease patients.

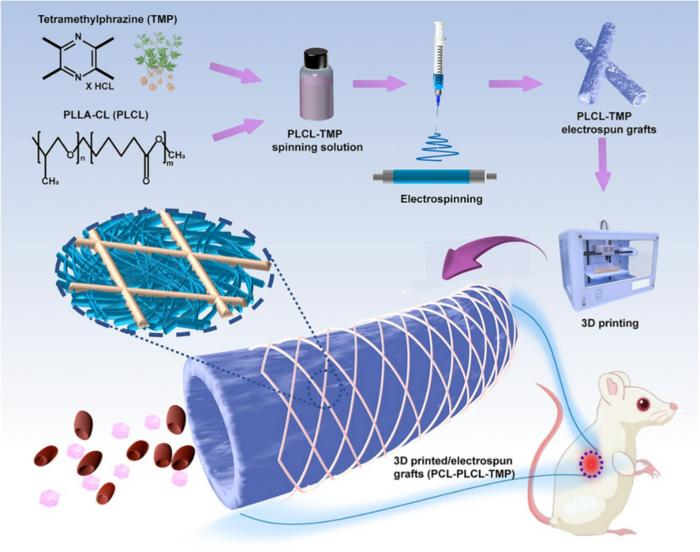

Schematic illustration of 3D printed electrospun vascular graft loaded with TMP. Image Credit: Burns & Trauma

Cardiovascular disease, responsible for over 18 million deaths annually, often necessitates vessel replacement due to severe stenosis or occlusion. However, the availability of autologous blood vessels is limited, prompting significant interest in vascular tissue engineering.

Nonetheless, thrombosis and aneurysmal dilatation continue to be major obstacles. Given these difficulties, it is imperative to investigate novel approaches to the production of vascular grafts.

The researchers' study highlights the production, characterization, and successful implantation of the grafts in rat abdominal aortas.

This research was dedicated to creating vascular grafts to mitigate common surgical issues such as thrombosis and aneurysmal dilatation. The method involved a combination of electrospinning and 3D printing techniques.

Specifically, the inner layer of the grafts consists of electrospun poly (L-lactic-co-caprolactone) (PLCL) nanofibers, while the outer layer is made of 3D-printed polycaprolactone (PCL) microfibers. This dual-layer construction aimed to improve both the mechanical stability and flexibility of the grafts.

Moreover, the inclusion of tetramethylpyrazine (TMP), a compound extracted from the traditional Chinese herb Ligusticum chuanxiong, imbues the grafts with notable antiplatelet and anticoagulant features.

Laboratory tests revealed that these grafts effectively minimized platelet adhesion and demonstrated excellent cytocompatibility with human umbilical vein endothelial cells. Further, in vivo testing using rat abdominal aorta replacements showed outstanding biocompatibility and mechanical durability for up to six months. The grafts remained open, free from acute thrombosis or notable aneurysmal expansion, suggesting their potential suitability for clinical use.

This innovative technique offers a promising solution to overcome both mechanical and biological challenges in vascular tissue engineering, aiming to enhance patient outcomes in vascular graft implementations.

This study marks a significant advancement in vascular tissue engineering. The combination of electrospinning and 3D printing, along with the incorporation of TMP, has resulted in a vascular graft that not only meets mechanical requirements but also exhibits excellent blood compatibility. These findings pave the way for future clinical applications.

Dr. Hongbing Gu, Study Lead Researcher, School of Medicine, Shanghai Jiao Tong University

The advancement of 3D-printed, electrospun vascular grafts infused with TMP represents a promising step towards enhancing treatments for cardiovascular diseases. These innovative grafts could significantly decrease postoperative complications like thrombosis and aneurysmal dilatation, thereby improving patient outcomes.

Future research will aim to assess the long-term effectiveness of these grafts in larger animal models and to delve deeper into the molecular processes that underpin vascular regeneration.

Journal Reference:

Shen, Y., et al. (2024) Development of 3D printed electrospun vascular graft loaded with tetramethylpyrazine for reducing thrombosis and restraining aneurysmal dilatation. Burns and Trauma. doi.org/10.1093/burnst/tkae008