Reviewed by Lexie CornerJul 23 2024

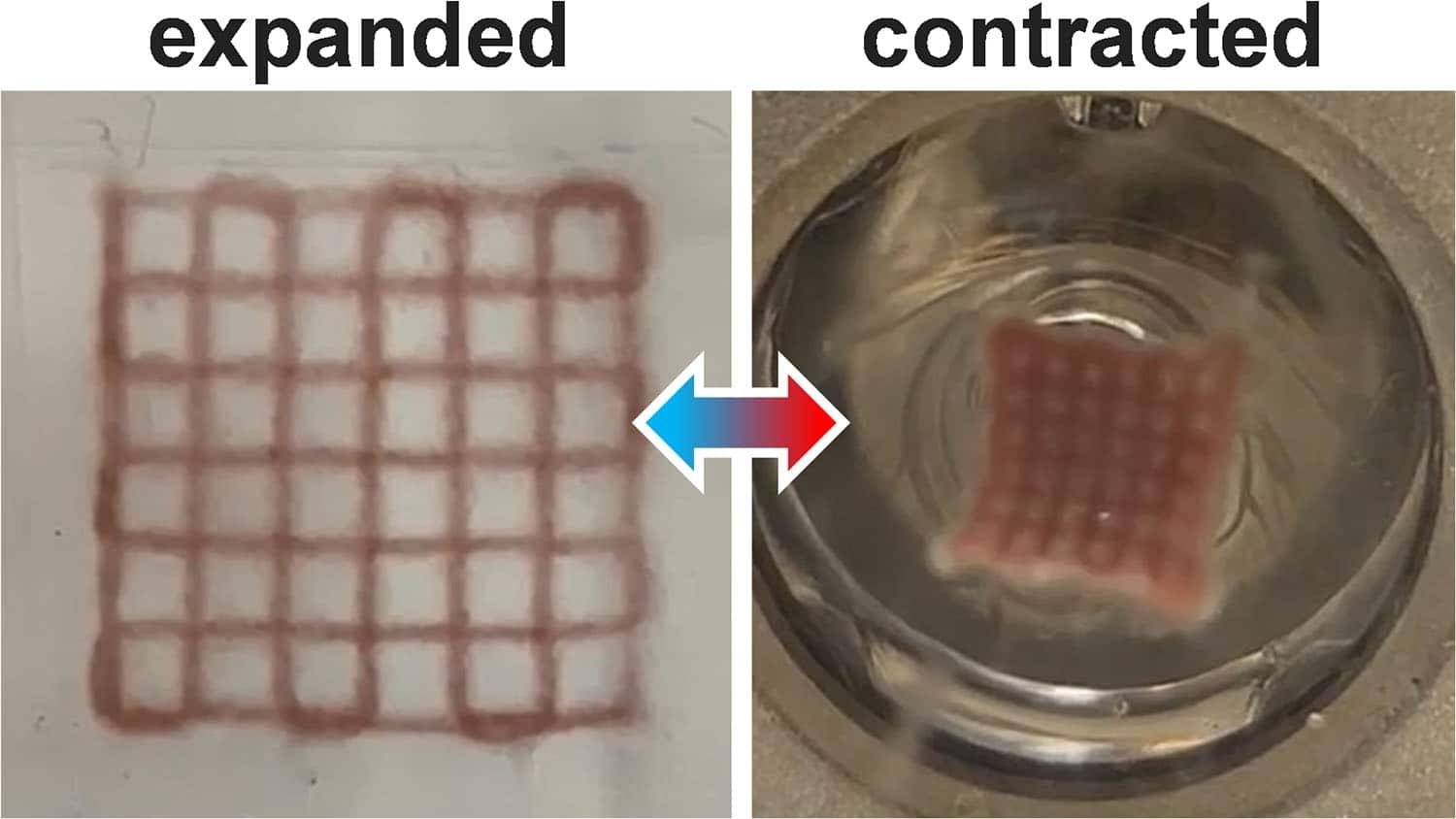

In a study published in Polymers, an international team of researchers placed gold nanorods in hydrogels that can be 3D printed to build structures that constrict when exposed to light and then expand when the light is withdrawn. Since the expansion and contraction may be repeated, 3D-printed objects can be used as remotely controlled actuators.

Image Credit: NC State University

We knew that you could 3D print hydrogels that would contract when heated. And we knew that you could incorporate gold nanorods into hydrogels that would make them photoresponsive, meaning that they would contract in a reversible manner when exposed to light. We wanted to find a way to incorporate gold nanorods into hydrogels that would allow us to 3D print photoresponsive structures.

Joe Tracy, Study Co-Corresponding Author and Professor, North Carolina State University

Hydrogels are polymer networks that contain water. Examples include everything from contact lenses to the absorbent material used in diapers. Technically, the researchers did not use the 3D printer to produce a hydrogel. Instead, they printed a solution containing gold nanorods and the components required to make a hydrogel.

And when this printed solution is exposed to light, the polymers in the solution form a cross-linked molecular structure. This turns the solution into a hydrogel, with the trapped gold nanorods distributed throughout the material.

Julian Thiele, Co-Corresponding Author and Chair, Organic Chemistry, Otto von Guericke University Magdeburg

Since the pre-hydrogel solution produced by the 3D printer has a very low viscosity, it cannot be printed onto a standard substrate; otherwise, it will result in a puddle rather than a 3D structure.

To address this issue, the researchers printed the solution as a transparent slurry of gelatin microparticles in water. The printer nozzle may penetrate the gelatin slurry and print the solution to the required shape. Since gelatin is transparent, light can seep through the matrix, transforming the solution into a solid hydrogel. After that, the entire thing is immersed in warm water, which dissolves the gelatin and leaves behind the 3D hydrogel structure.

When these hydrogel frameworks are exposed to light, the embedded gold nanorods convert the light to heat. This causes the polymers in the hydrogel to contract, forcing water out and reducing the structure. However, when the light is turned off, the polymers cool down and resume collecting water, restoring the hydrogel structure to its previous proportions.

A lot of work has been done on hydrogels that contract when exposed to heat. We have now demonstrated that you can do the same thing when the hydrogel is exposed to light, while also having the capability to 3D print this material. That means applications that previously required direct application of heat could now be triggered remotely with illumination.

Melanie Ghelardini, Study First Author and Former Ph.D. Student, North Carolina State University

Thiele added, “Instead of applying conventional mold casting, 3D printing of hydrogel structures offers nearly unlimited freedom in design. And it allows for preprogramming distinct motion during light-triggered contraction and expansion of our photoresponsive material.”

Jameson Hankwitz, a former graduate student at NC State; Martin Geisler, Niclas Weigel, Nicolas Hauck, and Jonas Schubert of the Leibniz Institute of Polymer Research Dresden; and Andreas Fery of the Leibniz Institute of Polymer Research Dresden and Technische Universität Dresden are the study co-authors.

This study was funded by the National Science Foundation (grant number 1803785), the German Research Foundation (DFG) Research Training Schools 1865: Hydrogel-based microsystems and 2767 (project number 451785257), the Alexander von Humboldt Foundation, the Dresden Center for Intelligent Materials, and the European Union's Horizon 2020 research and innovation program (grant number 852065).

Journal Reference:

Ghelardini, MM., et al. (2024) 3D-Printed Hydrogels as Photothermal Actuators. Polymers. doi:10.3390/polym16142032