Reviewed by Danielle Ellis, B.Sc.Sep 4 2024

In a study published in the Journal of Catalysis, researchers supervised by Associate Professor Tomohiro Hayashi of the Tokyo Institute of Technology (Tokyo Tech) and Professor Chia-Ying Chiang of the National Taiwan University of Science and Technology, Taiwan, created a highly selective and effective glycerol electrooxidation (GEOR) process that could contribute to the generation of valuable 3-carbon (3C) products.

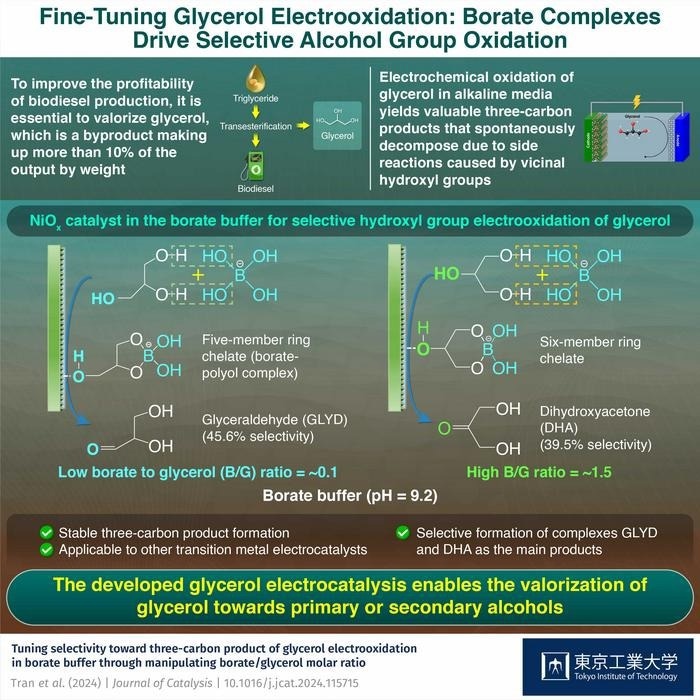

Biodiesel, a greener alternative to regular diesel, has been found to lower CO2 emissions by up to 74%. Transesterification converts triglycerides into biodiesel while also creating glycerol as a low-value byproduct. Since glycerol accounts for around 10% of total output, efforts have concentrated on increasing its value.

One way is electrochemical oxidation, which converts glycerol into high-value three-carbon molecules such as dihydroxyacetone (DHA) and glyceraldehyde (GLYD); however, previous efforts frequently produced unstable or low-value products under strongly alkaline conditions.

Hayashi and Chiang stated, “Establishing an electrochemical route for a highly selective and efficient glycerol electrooxidation process to desirable 3C products is essential for biodiesel production.”

Image Credit: Scharfsinn/Shutterstock.com

The structure of glycerol makes selective oxidation difficult. Glycerol has three -OH groups, two on the primary carbon atoms and one on the secondary carbon atom. This configuration introduces steric hindrance, making it difficult for reactants to target specific -OH groups for oxidation.

In alkaline conditions, the –OH groups produce undesirable side reactions that break carbon-carbon bonds, producing two- or one-carbon compounds rather than the expected three-carbon products.

To address this, the researchers carried out GEOR with sodium borate and bicarbonate buffer as a mild alkaline electrolyte and a nickel-oxide (NiOx) catalyst. The sodium borate protects specific –OH groups, boosting reaction selectivity, whilst the NiOx catalyst increases electrooxidation efficiency. Sodium borate forms coordination complexes with glycerol’s main and secondary alcohol groups, yielding GLYD and DHA respectively.

However, the final product is determined by the borate/glycerol ratio. To investigate how different concentrations of glycerol and borate affect the electrooxidation process, a fixed concentration of 0.1 M borate buffer was combined with varying concentrations of glycerol (0.01, 1, 2.0 M) and a fixed concentration of 0.1 M glycerol with varying concentrations of borate buffer (0.01, 0.05, 0.10, and 0.15 M) while keeping a pH of 9.2.

The selectivity for 3C products, particularly DHA, was shown to improve with higher borate concentrations; the maximum selectivity of up to 80% was noted at a borate concentration of 0.15 M. This enhancement is ascribed to the borate solution's improved buffer capacity, which keeps the pH steady during the process and keeps the borate-glycerol complex stable for further oxidation into 3C compounds.

On the other hand, when glycerol concentration increased, 3C product yield and selectivity decreased. With a 51% selectivity, GLYD was the primary product at a glycerol concentration of 1 M.

The researchers discovered using Raman spectroscopy that the production of distinct glycerol-borate complexes was connected to the variation in the type of 3C product. Higher borate concentrations prefer six-membered ring complexes, which promote secondary OH oxidation and DHA synthesis.

On the other hand, five-membered ring complexes are preferred at higher glycerol concentrations, which results in primary –OH oxidation and GLYD production.

“Five-membered ring complexes were more likely to form in the electrolyte with a borate-to-glycerol ratio of 0.1, whereas six-membered ring complexes became more prominent in the electrolyte with a borate-to-glycerol ratio of 1.5,” Hayashi and Chiang noted.

These results offer a viable method for converting glycerol into useful products, increasing the biodiesel production process’ sustainability and profitability.

Journal Reference:

Tran, G.-S., et al. (2024) Tuning selectivity toward three-carbon product of glycerol electrooxidation in borate buffer through manipulating borate/glycerol molar ratio. Journal of Catalysis. doi.org/10.1016/j.jcat.2024.115715