Reviewed by Danielle Ellis, B.Sc.Sep 5 2024

A research team at the Ulsan National Institute of Science and Technology (UNIST) and at the Korea Institute of Energy Research (KIER) developed a key technology for manufacturing electrodes that can regulate dendrite formation in aqueous zinc batteries. The study has been published in Advanced Energy Materials.

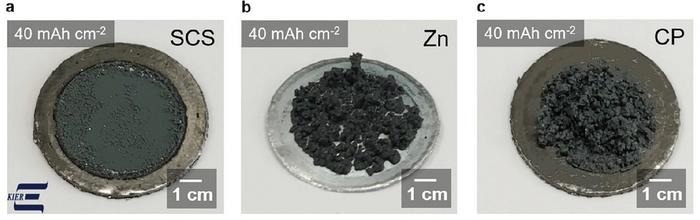

The developed electrode (a) shows more uniform deposition compared to the zinc (b) and carbon (c) electrode. Image Credit: Korea Institute of Energy Research (KIER)

The developed electrode (a) shows more uniform deposition compared to the zinc (b) and carbon (c) electrode. Image Credit: Korea Institute of Energy Research (KIER)

The study involved Professor Jaephil Cho at Ulsan National Institute of Science and Technology (UNIST) and Dr. Jung-Je Woo of the Gwangju Clean Energy Research Center at the Korea Institute of Energy Research (KIER).

In contrast to lithium-ion batteries, which use volatile liquid electrolytes, aqueous zinc batteries are secondary batteries that use water as the electrolyte, eliminating fire hazards and improving environmental friendliness. Furthermore, compared to lithium-ion batteries, which only use one electron per ion, aqueous zinc batteries have the potential to offer more than twice the capacity due to their usage of two electrons per ion.

One major barrier to the technology’s commercialization is that dendrites form more actively in aqueous zinc batteries than in lithium-ion batteries. Utilizing copper oxide, the research team was able to regulate dendrite formation and encourage consistent zinc deposition. Batteries with electrodes created in this manner showed a lifespan that was more than ten times longer than that of traditional batteries.

Adding promoters, such as copper, to speed up zinc’s initial growth and direct uniform deposition was the main strategy used in the past to suppress dendrite formation. The issue with this strategy was that the battery would repeatedly cycle between charging and discharging, which would cause dendrite formation to recur.

In response, the research team developed a technique that uses copper oxide to gradually control dendrite formation. Similar to ordinary copper, copper oxide directs the deposition of zinc and encourages its initial growth. Furthermore, compared to ordinary copper, copper oxide has a conductivity that is optimized for depositing zinc in a uniform distribution, enabling more effective deposition.

Copper oxide gradually self-assembles into a scaffold after evenly dispersing zinc. Comparable to a fence, the scaffold inhibits aberrant growth and deposition of zinc. Due to this, even with frequent cycles of charging and discharging, dendrite formation can be continuously prevented.

The research team's technology-powered batteries had a lifespan of over ten times longer than that of traditional aqueous zinc batteries, which raised the possibility of commercialization.

The research team achieved a world-leading capacity of 60 mAh/cm² by effectively controlling the deposition of zinc. They also verified that the technology could be used for large-area electrodes measuring 64 cm², and they showed durability through more than 3,000 battery performance tests.

The significance of this research is that it provides a solution to the challenge of dendrite formation in metal batteries such as aqueous zinc batteries using low-cost processes and materials like copper oxide.

Dr. Jung-Je Woo, Study Lead Researcher, Ulsan National Institute of Science and Technology

Woo added, “We aim to contribute to the commercialization of aqueous batteries through follow-up research that standardizes and systematizes the developed electrodes.”

Journal Reference:

Kim, J., et al. (2024) Self-Converted Scaffold Enables Dendrite-Free and Long-Life Zn-Ion Batteries. Advanced Energy Materials. doi.org/10.1002/aenm.202401820