A recent article published in Nature Communications presents a microstructure-sensitive model designed to understand the impact of grain-level chemo-mechanics on the degradation of composite cathodes in solid-state lithium (Li)-ion batteries. The model illustrates the interplay between cathode microstructure, operating conditions, battery material micromechanics, and capacity decay.

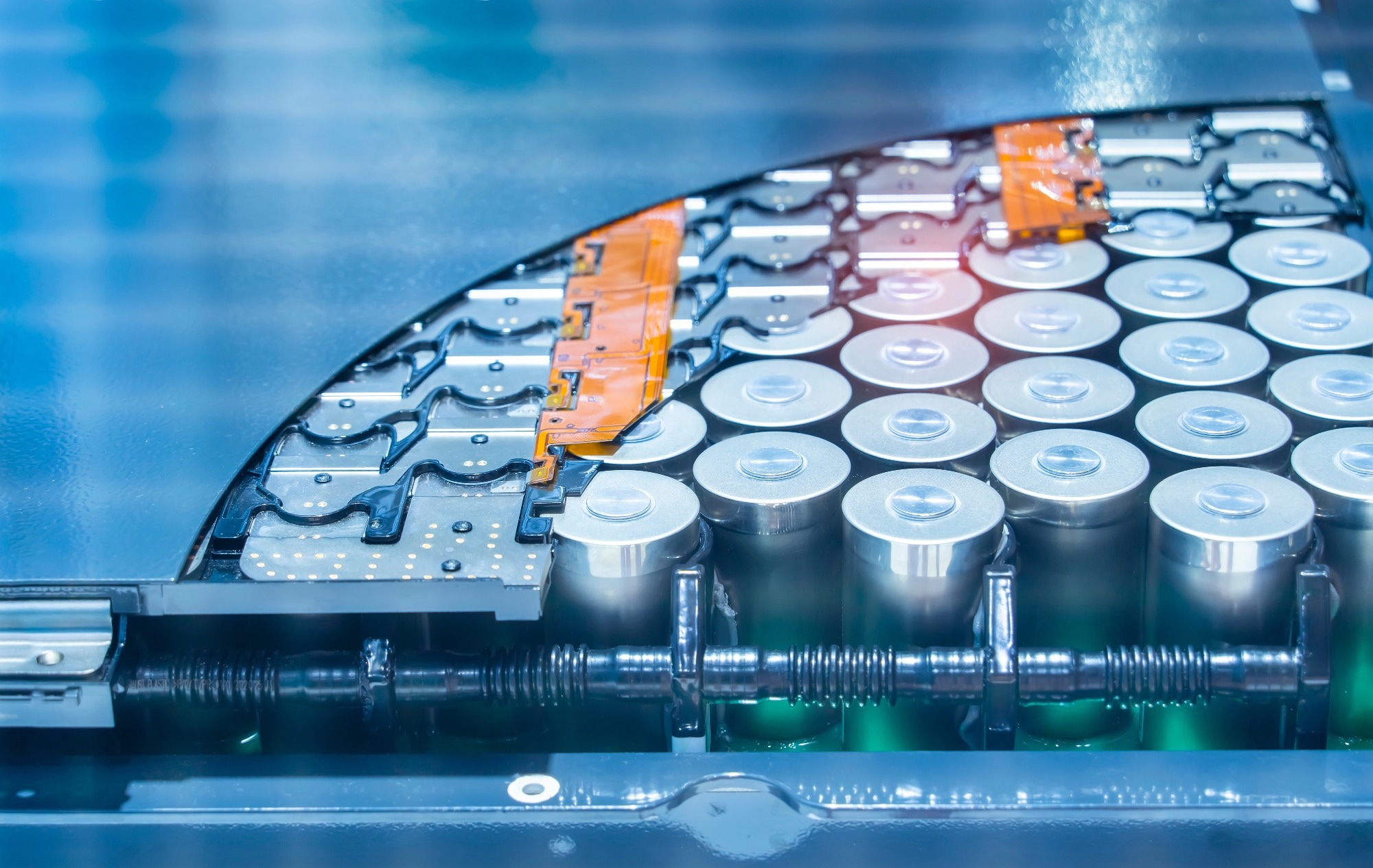

Image Credit: asharkyu/Shutterstock.com

Background

Solid-state Li-ion batteries with Ni-rich oxide cathodes and Li-metal anodes offer high theoretical specific energy, making them promising for electrochemical storage. However, Li intercalation-induced dimensional changes in these cathodes lead to crystal defect formation, causing contact mechanics issues between the cathode and solid electrolyte.

Addressing the challenges of cathode/electrolyte interface issues and crystal defect formation in composite cathodes requires a comprehensive understanding of the chemo-mechanics at battery-related length scales and strain rates. Atomic-scale simulations and high-resolution transmission electron microscopy (TEM) experiments have shown that dislocations caused by heterogeneous Li intercalation can lead to structural degradation in the cathode.

Chemo-mechanical simulations, including cohesive zone and phase-field damage models, have provided insights into microscopic mechanical fracture behavior in electrode materials. However, the effects of microstructure and (dis)charging protocols on crystal defect formation and resulting cathode structural degradation at the grain level are yet to be fully explored.

Methods

A thermodynamically consistent chemo-mechanical model was developed within a finite strain framework to account for the significant volume changes caused by Li intercalation in Ni-rich NMC cathodes. The model included anisotropic and concentration-dependent material properties to accurately represent the behavior of composite cathodes.

To efficiently solve the coupled governing equations, a large-scale parallel finite element solver based on the PETSc (Portable, Extensible Toolkit for Scientific Computation) numerical library was created. The model was implemented using DAMASK (Düsseldorf Advanced Material Simulation Kit) for simulation.

A three-dimensional volume element was used to represent the composite cathode microstructure. Specifically, an isolated Ni-rich NMC811 (LiNi0.8Co0.1Mn0.1O2) polycrystal particle, comprising 200 randomly oriented primary particles, was embedded in a uniform solid electrolyte (Li6.6La3Ta0.4Zr1.6O12).

The grain-level chemo-mechanical model was then used to describe the electrochemical reactions at the cathode/solid-electrolyte interface, Li intercalation within the cathode, lattice dimension changes, and the formation of dislocations.

The influence of lattice strain, resulting from dislocations, on oxygen deficiency in the NMC cathode was examined by calculating the formation energy of oxygen vacancies under mechanical strain. While maximum principal stress distribution was employed to assess contact mechanics issues, the model did not explicitly account for mechanical fracture. Additionally, the solid electrolyte was assumed to undergo only isotropic elastic deformation.

Results and Discussion

Anisotropic elastic stiffness and lattice dimension changes in the NMC cathode had a significant impact on the contact mechanics at the cathode/solid-electrolyte interface and the grain boundaries of the primary particles. During discharge, the cathode particle expanded in volume, but most regions at the cathode/solid-electrolyte interface experienced substantial tensile stress due to the anisotropic chemical expansion of the primary particles in both single-crystal and polycrystal cathodes.

Additionally, the anisotropic deformation of the primary particles during charging led to high-stress levels at the cathode/solid-electrolyte interface and grain boundaries within the polycrystalline cathode particle. These anisotropic lattice dimension changes during (de)lithiation, combined with microstructural heterogeneity, could potentially lead to mechanical failure at the cathode/solid-electrolyte interface and fragmentation of primary particles at grain boundaries.

The effectiveness of the developed chemo-mechanical model was demonstrated by its good agreement with experimental voltage-capacity profiles of the polycrystalline cathode during galvanostatic discharge tests. The tests also indicated that the capacity-rate trade-off in single-crystal and polycrystalline cathodes could be improved by reducing the size of the secondary particles.

When considering the influence of secondary particle size and discharge rate on the oxygen-deficient phase within the secondary particles, it was found that significant bulk structural degradation occurred in secondary particles larger than ~8 µm when exposed to discharge rates exceeding 1C, leading to a loss of over 10 % of active materials.

Therefore, both the microstructure of the cathode and the operating conditions played a critical role in the amount and distribution of the oxygen-deficient phase, which, in turn, affected the electrochemical performance of the composite cathodes.

This phase transition-induced capacity loss was attributed to several factors, including the depletion of active materials (a thermodynamic effect) and the obstruction of Li-ion intercalation pathways (a kinetic effect). Additionally, secondary particles experienced a kinetically induced capacity loss of more than 0.1 when the discharge rate exceeded 1C due to the accumulation of crystal defects and structural degradation at the particle’s periphery.

Conclusion

The researchers successfully developed a mesoscale chemo-mechanical constitutive model to examine the influence of grain-level chemo-mechanics on the electrochemical performance and degradation mechanisms in composite cathodes of solid-state batteries.

Integrating multi-scale experimental and theoretical findings revealed extensive dislocation formation (over 12 % plastic shear locally) in Ni-rich cathodes during discharge. This behavior was attributed to large compositional strains, crystalline anisotropy, and non-equilibrium Li-ion intercalation dynamics.

This study's insights into crystalline anisotropy and grain-level chemo-mechanics in defect formation and mechanical degradation can help improve the design of energy storage systems.

Journal Reference

Liu, C., Roters, F., Raabe, D. (2024). Role of grain-level chemo-mechanics in composite cathode degradation of solid-state lithium batteries. Nature Communications. DOI: 10.1038/s41467-024-52123-w, https://www.nature.com/articles/s41467-024-52123-w

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.