Reviewed by Lexie CornerSep 20 2024

Scientists at Max Planck have developed an environmentally friendly technique that integrates metal extraction, alloying, and processing into a single phase. The study has been published in the journal Nature.

Synthesis of Fe-36Ni invar alloy from iron and nickel oxides. Image Credit: Nature 2024, DOI: 10.1038/s41586-024-07932-w

Synthesis of Fe-36Ni invar alloy from iron and nickel oxides. Image Credit: Nature 2024, DOI: 10.1038/s41586-024-07932-w

Around 10 % of the world's CO2 emissions are attributed to metal production, with nickel and iron generating up to 14 tons of CO2 per ton of metal, and even higher amounts depending on the ore used. These metals are crucial for creating Invar alloys, which have low thermal expansion and are vital for industries such as energy, precision instruments, aerospace, and cryogenic transport.

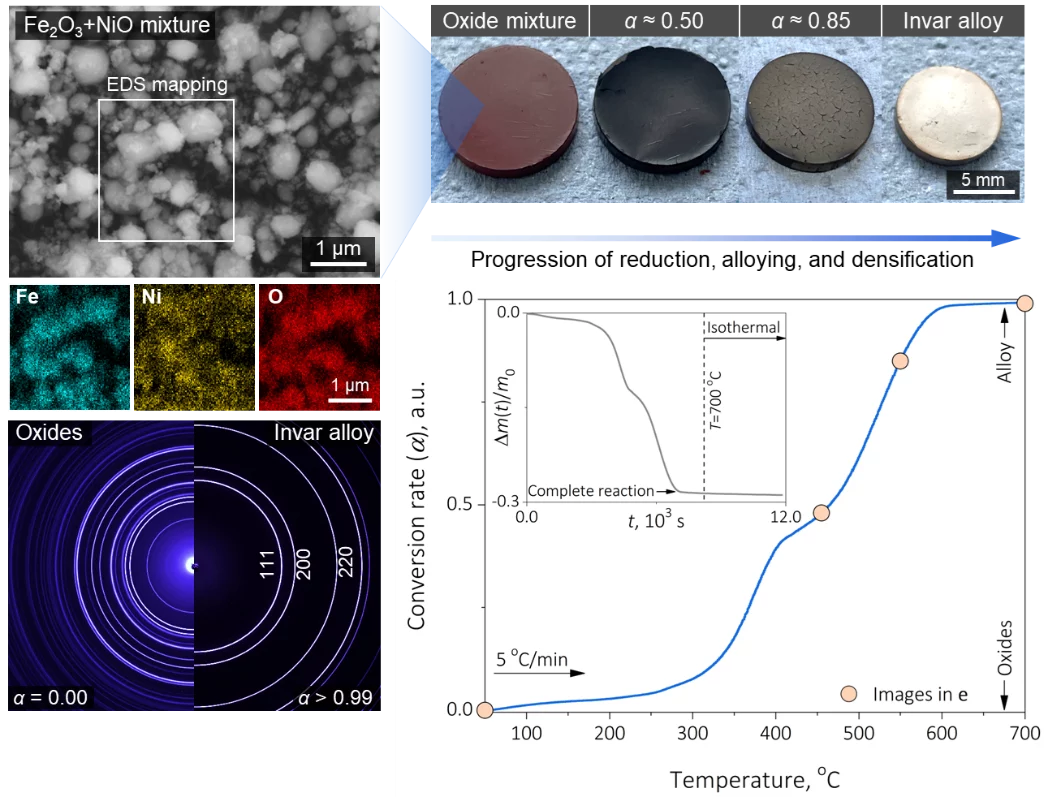

Scientists at the Max Planck Institute for Sustainable Materials (MPI-SusMat) have devised a novel method to produce Invar alloys without CO2 emissions, significantly reducing energy consumption. This innovative process integrates metal extraction, alloying, and thermomechanical processing into a single reactor and step, challenging traditional distinctions in metallurgy and enabling direct conversion from oxides to valuable products in a single solid-state operation.

One-Step-Metallurgy Saves Energy and CO2

We asked ourselves: Can we produce an alloy with near-optimized microstructure-property combination directly from ores or oxides with zero CO2 emission?

Dr. Shaolou Wei, Humboldt Research Fellow and Study First Author, Max Planck Institute for Sustainable Materials

Traditionally, alloy production involves three steps: first, metallic ores are reduced to a smaller form; next, liquid elements are combined to form the alloy; and finally, thermomechanical treatments are applied to achieve the desired properties. Each of these energy-intensive processes relies on carbon as a reducing agent and energy carrier, resulting in substantial CO2 emissions.

The key idea is to understand the thermodynamics and kinetics of each element and use oxides with similar reducibility and mixability at around 700 °C. This temperature is far below the bulk melting point, which still allows us to extract metals from their oxide state and mix them into alloys via one single solid-state process step without reheating. Unlike conventional methods where ores are reduced using carbon, which results in carbon-contaminated metals, the team’s new method uses hydrogen as the reducing agent.

Dr. Shaolou Wei, Humboldt Research Fellow and Study First Author, Max Planck Institute for Sustainable Materials

Dierk Raabe, Managing Director, Professor, and Study Corresponding Author at Max Planck Institute for Sustainable Materials, said, “Using hydrogen instead of carbon brings four key advantages. First, the hydrogen-based reduction only produces water as a byproduct, meaning zero CO2 emissions. Second, it yields pure metals directly, eliminating the need to remove carbon from the final product, thus saving time and energy. Third, we do the process at comparably low temperatures, in the solid state. Fourth, we avoid the frequent cooling and reheating characteristic of conventional metallurgical processes.”

The refined grain size inherited from this process gives the final Invar alloys higher mechanical strength while still maintaining the low thermal expansion properties of conventionally produced Invar alloys.

Upscaling to Industrial Dimensions

Max Planck scientists have demonstrated the feasibility and potential of producing Invar alloys quickly, carbon-free, and energy-efficiently. However, scaling up this process to meet industrial demands requires overcoming three main challenges:

-

Managing Impurities in Industrial Oxides: While the researchers used pure oxides in their proof-of-concept work, industrial applications are likely to involve oxides with impurities. The process must be adapted to handle less refined materials without compromising the alloy's quality.

-

Cost of Hydrogen in Reduction Process: Although using pure hydrogen is effective, it is costly for large-scale operations. The team is exploring lower hydrogen concentrations at higher temperatures to optimize the balance between energy costs and hydrogen usage, making the process more commercially viable.

-

Need for Pressing Steps in Sintering: While the current process uses pressure-free sintering, incorporating pressing steps will likely be necessary to produce finely coarsened bulk materials on an industrial scale. This could further enhance the material's structural integrity while maintaining efficient production.

This versatile one-step process opens up new possibilities. Given its applicability to iron, nickel, copper, and cobalt, future research may focus on high-entropy alloys, which have the potential to create new materials like soft magnetic alloys, ideal for high-tech applications.

Using metallurgical waste instead of pure oxides is another promising direction. By filtering contaminants from waste materials, this method could turn industrial leftovers into valuable feedstock, significantly improving the sustainability of metal production.

This hydrogen-based method, which eliminates the need for high temperatures and fossil fuels, could greatly reduce the environmental impact of alloy production, paving the way for a more sustainable future in metallurgy.

Journal Reference:

Wei, S., et al. (2024) One step from oxides to sustainable bulk alloys. Nature. doi.org/10.1038/s41586-024-07932-w.