Reviewed by Danielle Ellis, B.Sc.Sep 27 2024

Researchers have created a new kind of sunscreen with titanium dioxide (TiO2) and lignin, a naturally occurring polymer, in a major development for the cosmetics industry. The novel application of a dual-modified lignin sub-microsphere to increase the SPF and improve the color of sunscreens is described in the study, which was led by Yarong Li and Zhiguang Tang and published in the Journal of Bioresources and Bioproducts.

Researchers develop a novel lignin sub-microsphere loaded with TiO2 for enhanced sunscreen capabilities. Image Credit: College of Light Industry and Food Engineering, Guangxi University, Nanning, 530004, China

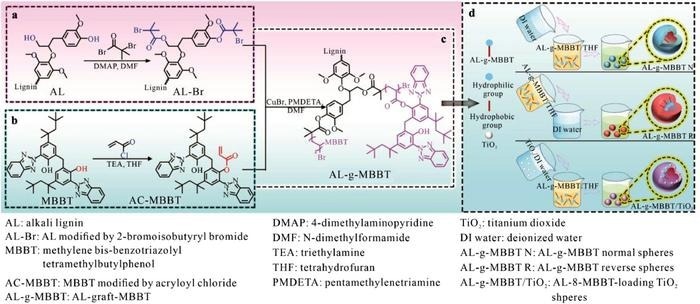

Lignin is a pulp industry byproduct that is well-known for its antioxidant and UV-absorbing qualities. However, because of its dark coloring and low SPF, its use in commercial sunscreens has been restricted. The researchers altered the physical and chemical structures of lignin in two different ways to address these issues. To create the polymer AL-g-MBBT, the team grafted methylene bis-benzotriazolyl tetramethylbutylphenol (MBBT) onto alkali lignin (AL). Next, this polymer was made into sub-micron spheres, both with and without TiO2 loaded in them.

The outcomes were astonishing. In comparison to sunscreens made without AL modification, which had an SPF of 4.74, sunscreens made with 10% AL-g-MBBT3 showed an SPF of 42.93. In addition, the altered lignin-based sunscreen had a significantly lighter color, with a color difference value (ΔE) of 45.6 as opposed to the unaltered AL's 49.5 ΔE, making it more attractive for cosmetic application.

The researchers further enhanced the sunscreen's performance by forming sub-micron spheres loaded with TiO2. These AL-g-MBBT3/TiO2@C sunscreens outperformed the sub-micron spheres without TiO2 loading and the unmodified AL, achieving SPFs of 66.20. With an ΔE value of 36.3, these sunscreens' color was also noticeably improved.

The study also assessed the photostability and biocompatibility of the sunscreen based on lignin. The outcomes demonstrated that even after three hours of UV irradiation, the sunscreen retained both its color and sun protection effectiveness. The modified lignin-containing sunscreen was also shown to be non-toxic to human keratinocytes in the biocompatibility tests, indicating that skin application is safe.

This research has significantly advanced the application of lignin, providing a high-performing and sustainable substitute for conventional sunscreen ingredients. The results may open the door for a fresh wave of efficient and environmentally friendly sunscreen formulations.

Journal Reference:

Li, Y., et al. (2024) Development of Methylene Bis-Benzotriazolyl Tetramethylbutylphenol-Grafted Lignin Sub-Microspheres Loaded with TiO2 for Sunscreen Applications. Journal of Bioresources and Bioproducts. doi.org/10.1016/j.jobab.2024.09.003