In a study published in Materials & Designs, researchers from Texas A&M University and Sandia National Laboratories have made significant advancements in a new joining technology called interlocking metasurfaces (ILMs). This technology uses shape memory alloys (SMAs) to improve a structure’s strength and stability compared to more conventional methods like bolts and adhesives.

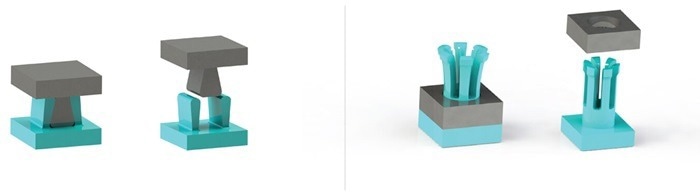

An individual cell of the two proposed versions of ILMs in their different engagement states. Image Credit: Dr. Ibrahim Karaman/Texas A&M Engineering

ILMs can potentially revolutionize the design of mechanical joints used in robotics, aerospace, and biomedical device manufacturing.

ILMs are poised to redefine joining technologies across a range of applications, much like Velcro did decades ago. In collaboration with Sandia National Laboratories, the original developers of ILMs, we have engineered and fabricated ILMs from shape memory alloys. Our research demonstrates that these ILMs can be selectively disengaged and re-engaged on demand while maintaining consistent joint strength and structural integrity.

Dr. Ibrahim Karaman, Professor and Head, Department of Materials Science and Engineering, Texas A&M University

ILMs allow two bodies to be joined by transmitting force and limiting movement, much like Legos or Velcro. This joining technique has been passive up until now, requiring force to engage.

The teams used SMAs, particularly nickel-titanium, which can regain their original shape after deformation by adjusting temperature, to design and fabricate active ILMs using 3D printing.

The ability to manipulate joining technology through temperature variations creates new opportunities for intelligent, flexible structures with more flexibility and functionality without sacrificing strength or stability.

Active ILMs have the potential to revolutionize mechanical joint design in industries requiring precise, repeatable assembly and disassembly.

Abdelrahman Elsayed, Graduate Research Assistant, Department of Materials Science and Engineering Texas, A&M University

Potential Uses of ILMs

Practical applications involve developing reconfigurable aerospace engineering parts where parts must be put together and taken apart several times. Active ILMs may further offer adaptable and flexible joints for robotic-enhancing functionality. Patients may have better options with biomedical devices that can adapt implants and prosthetics to their body’s movements and temperature.

The current findings used the shape memory effect of SMAs to recover the shape of the ILMs by applying heat. The researchers intend to expand on these discoveries by employing the superelasticity effect of SMAs to develop ILMs that can tolerate significant deformation and instantly recover under extremely high stress levels.

Karaman added, “We anticipate that incorporating SMAs into ILMs will unlock numerous future applications, though several challenges remain. Achieving superelasticity in complex 3D-printed ILMs will enable localized control of structural stiffness and facilitate reattachment with high locking forces. Additionally, we expect this technology to address longstanding challenges associated with joining techniques in extreme environments. We are highly enthusiastic about the transformative potential of ILM technology.”

Additional contributors include Taresh Guleria, a doctoral student in the industrial systems and engineering department, and Dr. Alaa Elwany, an associate professor in the Wm Michael Barnes '64 Department of Industrial and Systems Engineering.

The Texas A&M Engineering Experiment Station, Texas A&M Engineering’s official research agency, is in charge of overseeing funding for this study.

Journal Reference:

Elsayed, A. et. al. (2024) Active interlocking metasurfaces enabled by shape memory alloys. Materials & Designs. doi.org/10.1016/j.matdes.2024.113137