Reviewed by Lexie CornerOct 15 2024

Researchers from the Massachusetts Institute of Technology have demonstrated fully 3D-printed resettable fuses, essential components in active electronics that usually rely on semiconductors. However, the practical application of this concept remains distant. The study was published in the journal Virtual and Physical Prototyping.

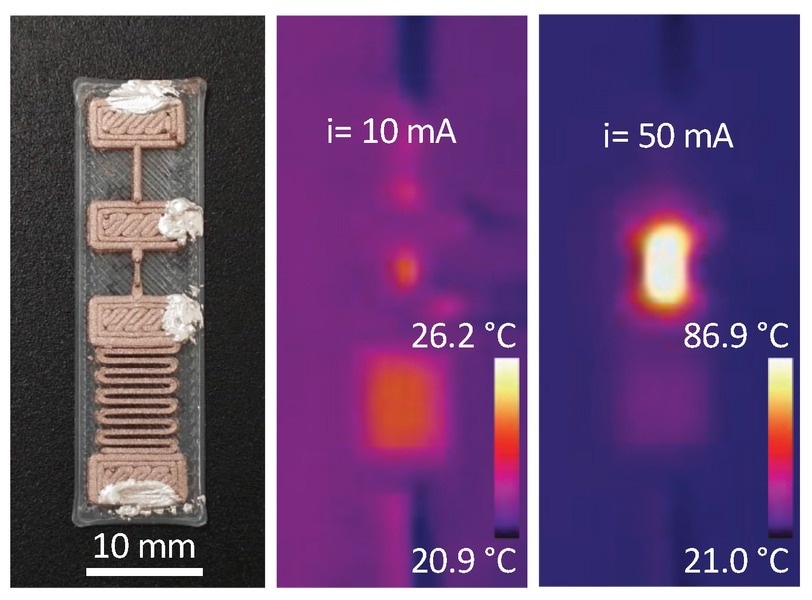

The devices are made from thin, 3D-printed traces of the copper-doped polymer. They contain intersecting conductive regions that enable the researchers to regulate the resistance by controlling the voltage fed into the switch. Image Credit: Researchers

The devices are made from thin, 3D-printed traces of the copper-doped polymer. They contain intersecting conductive regions that enable the researchers to regulate the resistance by controlling the voltage fed into the switch. Image Credit: Researchers

Semiconductor devices that receive, store, and process information are typically found in active electronics, which regulate electrical impulses. These components require clean-room environments and advanced fabrication technology, limiting their production to specialized manufacturing facilities.

The global electronics shortage during the COVID-19 pandemic was partly due to the lack of widespread semiconductor manufacturing, leading to higher consumer prices and affecting national security and economic growth. Without the requirement for semiconductors, it may become possible to 3D print fully functional electronic devices, making electronics production accessible to households, businesses, and labs worldwide.

The researchers demonstrated semiconductor-free devices capable of performing switching tasks similar to semiconductor-based transistors used in active electronics. These were created using standard 3D printing technology and a low-cost, biodegradable material. Although these 3D-printed electronics are not yet comparable to semiconductor transistors in complexity, they could be applied to basic control functions, such as regulating the speed of electric motors.

This technology has real legs. While we cannot compete with silicon as a semiconductor, our idea is not to necessarily replace what is existing but to push 3D printing technology into uncharted territory. In a nutshell, this is really about democratizing technology. This could allow anyone to create smart hardware far from traditional manufacturing centers.

Luis Fernando Velásquez-García, Principal Research Scientist and Study Senior Author, Microsystems Technology Laboratories, Massachusetts Institute of Technology

He collaborated on the study with lead author Jorge Cañada, a Graduate Student in Electrical Engineering and Computer Science.

An Unexpected Project

Certain impurities can be added to semiconductors, like silicon, to alter their electrical properties. This allows silicon devices to have both conductive and insulating areas, making silicon ideal for building transistors, a key component in modern electronics.

However, the researchers did not aim to replicate the function of silicon-based transistors in their 3D-printed, semiconductor-free devices. Instead, this project evolved from a prior one where they used extrusion printing, a method that melts filament and extrudes material through a nozzle layer by layer, to create magnetic coils.

While using a polymer filament mixed with copper nanoparticles, the team observed a notable behavior: when a high electric current was applied, the material's resistance spiked, but it quickly returned to its original level once the current stopped. This property, typically found in silicon and other semiconductors, enabled the team to design transistors capable of switching. Transistors form the basis of logic gates, which perform the binary computations essential for computing.

“We saw that this was something that could help take 3D printing hardware to the next level. It offers a clear way to provide some degree of ‘smart’ to an electronic device,” Velásquez-García said.

The researchers experimented with carbon-doped polymers, carbon nanotubes, and graphene to replicate the same effect in various 3D printing filaments. However, they were unable to identify another printable material that could function as a resettable fuse.

Their theory suggests that when the material is heated by the electric current, the copper particles disperse, causing a spike in resistance. As the material cools, the copper particles come back together, and the resistance decreases. Additionally, they believe the polymer base of the material undergoes a transformation called the polymeric positive temperature coefficient. This process causes the polymer to become crystalline when heated and revert to an amorphous state as it cools.

For now, that is our best explanation, but that is not the full answer because that doesn’t explain why it only happened in this combination of materials. We need to do more research, but there is no doubt that this phenomenon is real.

Luis Fernando Velásquez-García, Principal Research Scientist and Study Senior Author, Microsystems Technology Laboratories, Massachusetts Institute of Technology

3D-Printing Active Electronics

The researchers leveraged this effect to 3D print switches that could be used to create logic gates without semiconductors in a single step.

The devices were made using thin, 3D-printed traces of copper-doped polymer. By adjusting the voltage applied to the switch, the researchers were able to alter the resistance through the intersecting conductive zones in the material.

While the performance of these devices does not match that of silicon-based transistors, they could be used for basic control and processing tasks, such as switching a motor on and off. The tests showed the devices remained functional without any signs of degradation after 4,000 switching cycles.

However, there are limitations. Due to the physics of extrusion printing and the material properties, the researchers could only print switches a few hundred microns in size, whereas modern electronic transistors can be just a few nanometers in diameter.

“The reality is that there are many engineering situations that don’t require the best chips. At the end of the day, all you care about is whether your device can do the task. This technology is able to satisfy a constraint like that,” he said.

Their method employs a biodegradable material, which consumes less energy and produces less waste compared to traditional semiconductor manufacturing. The approach also offers the possibility of incorporating other materials, such as magnetic microparticles, into the polymer filament to enable additional functionalities.

Looking ahead, the researchers aim to 3D print fully functional devices using this method, with the goal of creating a magnetic motor solely through extrusion printing. They also plan to refine the process to develop more complex circuits and explore the limits of these devices' capabilities.

This paper demonstrates that active electronic devices can be made using extruded polymeric conductive materials. This technology enables electronics to be built into 3D-printed structures. An intriguing application is on-demand 3D printing of mechatronics onboard spacecraft.

Roger Howe, William E. Ayer Professor, Engineering, Emeritus, Stanford University

Howe was not involved in the study. The research was supported, in part, by Empiriko Corporation.

Journal Reference:

Cañada, J., et al. (2024) Semiconductor-free, monolithically 3D-printed logic gates, and resettable fuses. Virtual and Physical Prototyping. doi.org/10.1080/17452759.2024.2404157.