Reviewed by Lexie CornerOct 15 2024

In a study published in ACS Applied Materials and Interfaces, Dr. Kyung Tae Kim from the Nano Materials Research Division at KIMS developed a bismuth telluride (Bi-Te)-based thermoelectric material with artificially created atomic-scale defects. The research proposes a method to improve the material's properties, aimed at capturing and utilizing wasted thermal energy more effectively.

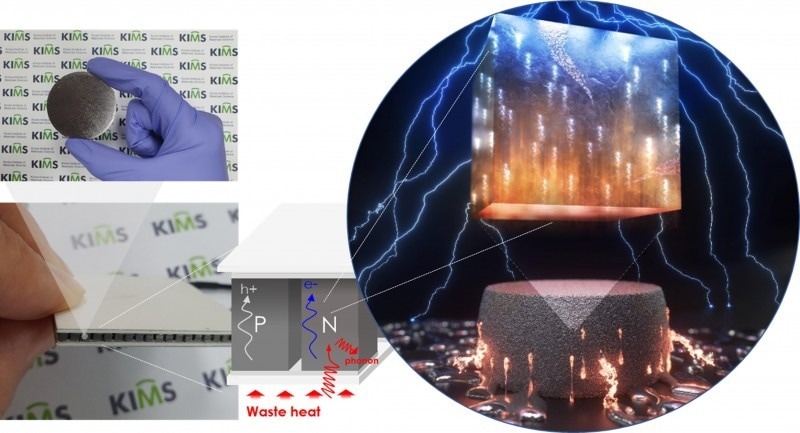

Conceptual diagram of the thermoelectric device and electric energy generation based on a developed thermoelectric semiconductor wafer. Image Credit: Korea Institute of Materials Science (KIMS)

Conceptual diagram of the thermoelectric device and electric energy generation based on a developed thermoelectric semiconductor wafer. Image Credit: Korea Institute of Materials Science (KIMS)

This semiconductor technology is applied in thermoelectric power generators, which recover waste heat from transportation and industrial sources, such as factories, cars, and ship engines, operating below 200°C to generate electricity. These generators utilize both p-type and n-type semiconductors to convert temperature differences into electrical energy and vice versa.

While past studies have focused on enhancing p-type thermoelectric materials made of tellurium (Te) and bismuth (Bi), progress in n-type thermoelectric semiconductors, which contain selenium (Se), has lagged due to challenges in controlling their composition and microstructure. This has slowed improvements in their properties, hindering the commercialization of thermoelectric technology.

The research team achieved a breakthrough by concentrating on n-type thermoelectric semiconductors, critical to determining thermoelectric generator performance. The key to this advancement lies in the innovative manufacturing process and doping materials.

Doping materials are substances added to semiconductors to enhance their electrical conductivity. The research team replaced Se with antimony (Sb) as a doping material in n-type bismuth telluride, leveraging antimony’s proven success in improving the performance of p-type bismuth telluride.

During the production process, the team introduced "atomic defects" to stimulate electron formation and created "dislocation networks" to scatter lattice phonons, which are responsible for heat transfer. This innovation led to reduced thermal conductivity and increased electrical conductivity. By utilizing powder metallurgy, the team was able to easily produce thermoelectric materials in various sizes and shapes, optimizing the material's thermal and electrical properties.

The resulting n-type thermoelectric semiconductor showed a significant improvement in energy conversion efficiency, more than doubling electrical conductivity while reducing thermal conductivity. This advancement is expected to enhance the recycling of waste heat, including low-temperature sources like body heat or industrial heat up to 200 °C.

The thermoelectric power generator market is forecasted to grow at a compound annual growth rate (CAGR) of 8.2 %, reaching $1.18 billion by 2029. The research team is collaborating with LIVINGCARE Co., Ltd. on thermoelectric power generation projects and with Hyundai Motor Company's Ulsan plant on a study to recover waste heat from casting molds.

This study has laid a stepping stone to solving the property control of n-type thermoelectric semiconductor, which has been an obstacle to recycling various types of waste heat below 200 ℃. The significance lies in the development of nanostructured thermoelectric material technology with controlled atomic-level defects using traditional powder metallurgy technology.

Dr. Kyung Tae Kim, Nano Materials Research Division, Korea Institute of Materials Science

The Bridge Convergence Project (Thermoelectric Research Center for Waste Heat Recovery) of the National Research Foundation of Korea and the Fundamental Research Project of KIMS funded this study. The findings of the study were released on July 31st, 2024, in the esteemed academic journal Applied Materials & Interfaces (IF: 11.1/First author: Senior Researcher Soo-ho Jung) by the American Chemical Society, and the paper was also selected as the journal’s cover feature.

Journal Reference:

Jung, S.-O. et. al. (2024) Synergistic Tailoring of Electronic and Thermal Transports in Thermoelectric Se-Free n-Type (Bi,Sb)2Te3. ACS Applied Materials and Interfaces. doi.org/10.1021/acsami.4c06978