In a study published in ChemSusChem, Worcester Polytechnic Institute researchers propose that treating iron with the electrolyte additive silicate could result in a high-performance alkaline battery anode.

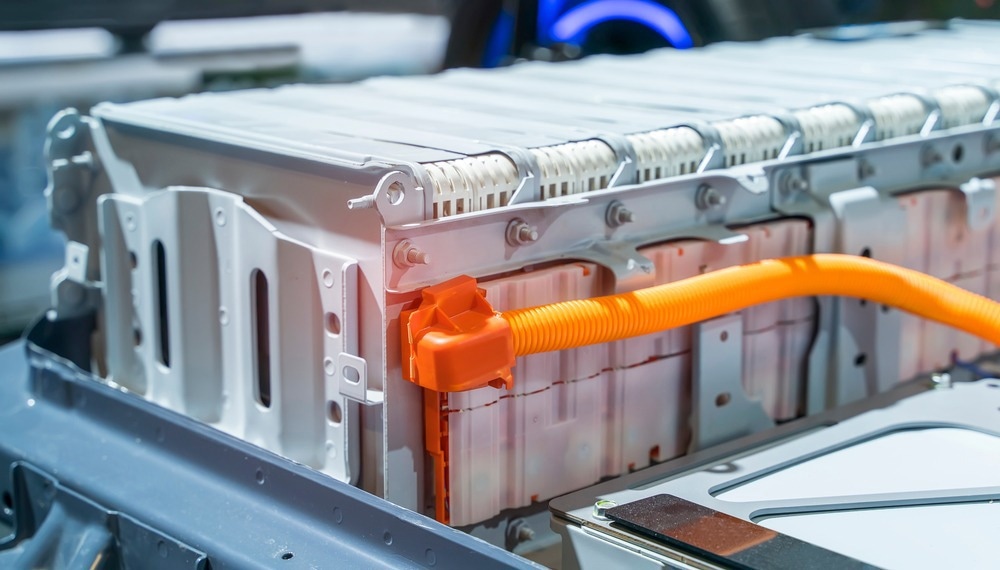

Image Credit: asharkyu/Shutterstock.com

There are drawbacks to the world’s quick switch to renewable energy. At night, solar power decreases, while wind power fluctuates between rising and falling. New technologies are needed to store excess electrical grid energy and release it when needed.

Rechargeable lithium-ion batteries power various devices, including smartphones and electric vehicles. However, they rely on limited resources such as lithium, nickel, and cobalt, raising concerns about sustainability and cost.

Xiaowei Teng, the James H. Manning Professor of Chemical Engineering at WPI, is leading a team investigating new battery technologies for grid energy storage.

Iron, the second most abundant metal in the Earth's crust after aluminum, is significantly more sustainable than nickel and cobalt. The United States recycles over 40 million metric tons of scrap iron and steel every year.

Teng points out that iron is already utilized as an alkaline battery anode in iron-nickel alkaline batteries, which Thomas Edison created in the 1900s. However, because hydrogen gas is formed during charging and inert iron oxide is formed during discharging, these batteries have a low energy efficiency and storage capacity.

You don’t want hydrogen gas formation when charging a battery. It impairs the energy efficiency of the battery system considerably. Without addressing these technical challenges, iron alkaline batteries are less attractive for modern energy storage systems to be coupled with electric grids.

Xiaowei Teng, James H. Manning Professor, Chemical Engineering, Worcester Polytechnic Institute

The team stated in a cover story published in ChemSusChem on October 7th, 2024, that they could charge a battery without creating hydrogen by incorporating silicate into the electrolytes.

According to Sathya Jagadeesan, a PhD candidate at WPI and the study's lead author, silicate, a chemical compound made of silicon and oxygen, has long been used as an affordable simple agent in glass, cement, insulation, and detergents.

The group also found that silicate inhibits the production of hydrogen gas and interacts strongly with battery electrodes. According to Teng, the alkaline iron redox chemistries in iron-air and iron-nickel batteries for energy storage applications like microgrids or individual solar or wind farms could be enhanced by this new process.

Journal Reference:

Jagadeesan, S. N. et. al. (2024) Unlocking High Capacity and Reversible Alkaline Iron Redox Using Silicate-Sodium Hydroxide Hybrid Electrolytes. ChemSusChem. doi.org/10.1002/cssc.202400050