Reviewed by Lexie CornerOct 29 2024

Researchers at the Technical University of Berlin, HZB, IMTEK (University of Freiburg), and Siemens Energy have developed a highly efficient alkaline membrane electrolyzer with performance comparable to widely used PEM electrolyzers. This achievement is significant as it replaces costly and rare iridium with affordable nickel compounds as the anode catalyst. The findings were published in Nature Catalysis.

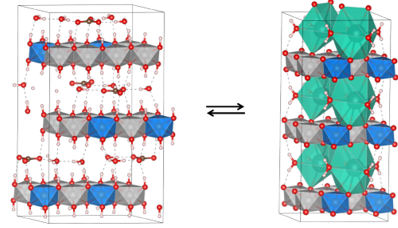

The catalytically inactive alpha phase (left) transforms through a phase transition to the highly active gamma phase (right). The team was able to elucidate the chemical details of this phase transition in detail using X-ray experiments at the LiXEdrom at BESSY II, as well as electrochemical and computer-aided analyses. © Image Credit: Hanna Trzesniowski

The catalytically inactive alpha phase (left) transforms through a phase transition to the highly active gamma phase (right). The team was able to elucidate the chemical details of this phase transition in detail using X-ray experiments at the LiXEdrom at BESSY II, as well as electrochemical and computer-aided analyses. © Image Credit: Hanna Trzesniowski

Using operando data, the team at BESSY II provided a detailed analysis of the catalytic activities, while collaborators from the USA and Singapore contributed a consistent molecular description. Prototype cells, developed in Freiburg using a novel coating technique, were then tested for functionality.

Hydrogen is expected to play a crucial role in the future energy system, serving as a fuel, energy storage medium, and essential raw material for the chemical industry. When produced through water electrolysis powered by solar or wind energy, hydrogen generation can be nearly climate-neutral.

Currently, efforts to scale up green hydrogen production primarily rely on conventional liquid alkaline electrolysis and proton-conducting membrane electrolysis (PEM). Alkaline exchange membrane (AEM) electrolyzers, however, offer a promising alternative by combining the advantages of both methods without requiring scarce metals like iridium.

AEM Electrolyzers without Iridium

Research teams from TU Berlin, HZB, the Department of Microsystems Engineering at the University of Freiburg, and Siemens Energy have demonstrated the first AEM electrolyzer capable of producing hydrogen nearly as efficiently as a PEM electrolyzer. They developed a technique to coat nickel double hydroxide complexes with iron, cobalt, or manganese directly onto an alkaline ion exchange membrane, offering a low-cost alternative to iridium.

Insight into Molecular Processes During Electrolysis at BESSY II

Researchers conducted operando measurements at the Berlin X-ray source BESSY II, specifically at the LiXEdrom end station, while the cell was actively electrolyzing. A theory team from the USA and Singapore assisted in interpreting the experimental data.

This enabled us to elucidate the relevant catalytic-chemical processes at the catalyst-coated membrane, in particular, the phase transition from a catalytically inactive alpha phase to a highly active gamma phase and the role of the various O ligands and Ni4+ centers in the catalysis. It is this gamma phase that makes our catalyst competitive with the current state-of-the-art iridium catalysts. Our work shows important similarities to iridium in the catalytic mechanism, but also some surprising molecular differences.

Peter Strasser, Professor, Technical University Berlin

This study has significantly enhanced the understanding of the catalytic mechanisms in the novel nickel-based electrode materials. Additionally, the newly developed coating technique for the membrane electrode offers promising scalability. The first fully operational lab cell has already been tested at IMTEK. This work demonstrates that an AEM water electrolyzer can achieve high efficiency, laying the foundation for further industrial evaluation.

Journal Reference:

Klingenhof, M., et al. (2024) High-performance anion-exchange membrane water electrolyzers using NiX (X = Fe,Co,Mn) catalyst-coated membranes with redox-active Ni–O ligands. Nature Catalysis. doi.org/10.1038/s41929-024-01238-w.