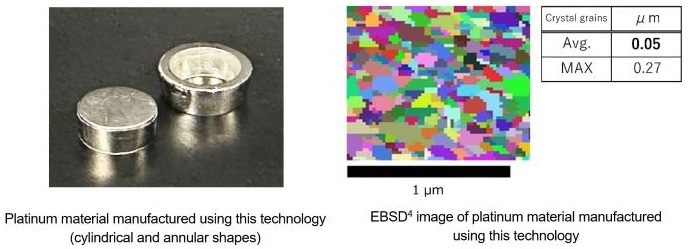

TANAKA Kikinzoku Kogyo K.K. (Head office: Chuo-ku, Tokyo; Representative Director & CEO: Koichiro Tanaka), which develops industrial precious metal products as one of the core companies of TANAKA Precious Metals, announced that it has succeeded in developing the world’s first bulk platinum with controlled crystal grain size in the nano scale.

Image Credit: TANAKA Kikinzoku Kogyo

The average grain size of a typical bulk metal is about 10 μm at the smallest. In this new technology, the average crystal grain size can be controlled in the nano scale. As a result, the developed pure platinum, with 99.9% or higher purity, has 10 times the hardness and times the strength of typical platinum materials.

It is known that the properties of metals, including precious metals, are enhanced by grain refinement. In recent years, steel and nonferrous metals with nano-sized crystal grains have been produced by deformation processing to apply extreme levels of plastic deformation and recrystallize their structures. While deformation processing temporarily hardens metal materials, when highly pure precious metal materials undergo the same process, the arrangement of atoms that form their crystalline structure changes and new crystal grains are nucleated and grown over periods of a few hours to a few days. As a result, the hardness of the material noticeably decreases (softens), and it has been very difficult to refine the crystal grains through deformation processing.

TANAKA Kikinzoku Kogyo has succeeded in manufacturing bulk platinum with controlled crystal grain size in the nano scale by optimizing the manufacturing process. The hardness and strength of the platinum materials manufactured by this technology are much higher than those of typical platinum materials. The developed platinum has a high density of small-angle grain boundaries, large-angle grain boundaries, dislocations, and other lattice defects within the material. Therefore, the developed platinum has properties that are clearly different from the properties of commonly known platinum materials, even without additive elements or alloying. As a new material with high purity and high functionality, it is expected to be applied to a wide field of industries, including the electronics and aerospace industries.

Material Development of Nanostructured Bulk

Many metal materials are polycrystalline, consisting of small crystal grains. It is considered that their properties can be improved by refinement of the crystal grains. The finer the grains, the higher the proportion of grain boundaries or lattice defects, such as dislocations, in the overall material. In materials with nanoscale grain, the ratio of lattice defects is incomparably higher than in commonly known materials, of which the physical properties and characteristics are usually discussed. As a result, unique physical properties and characteristics that are dramatically different from conventional materials are obtained.