In a recent study published in the journal National Science Review, scientists from Nanjing University and Nanjing Medical University successfully created an artificial muscle with mechanical characteristics akin to natural muscle tissue. The team used molecular design to create the artificial muscle through block Copolymerizing Biocompatible Perfluoropolyether (PFPE) and Polycaprolactone Diol (PCL).

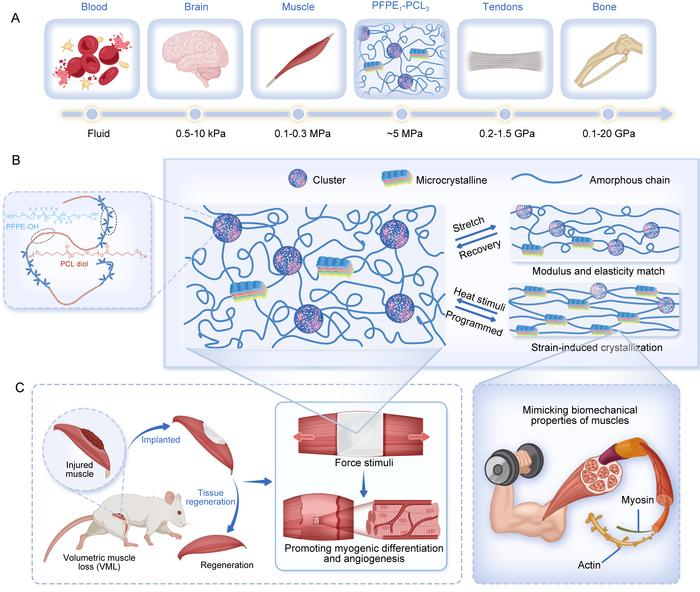

(A) A summary plot illustrating the elastic modulus range of the artificial muscle compared to representative biological tissues, highlighting the biomimetic mechanical properties of the artificial muscle. (B) A schematic representation of the designed multifunctional artificial muscle, showcasing its structural features tailored for enhanced functionality. (C) Demonstrations of the artificial muscle’s versatility: on the left, its ability to treat volumetric muscle loss by promoting myogenic differentiation and angiogenesis; on the right, its capacity to mimic the functional dynamics of natural muscle tissue. Image Credit: Cheng-Hui Li and Pengfei Zheng.

(A) A summary plot illustrating the elastic modulus range of the artificial muscle compared to representative biological tissues, highlighting the biomimetic mechanical properties of the artificial muscle. (B) A schematic representation of the designed multifunctional artificial muscle, showcasing its structural features tailored for enhanced functionality. (C) Demonstrations of the artificial muscle’s versatility: on the left, its ability to treat volumetric muscle loss by promoting myogenic differentiation and angiogenesis; on the right, its capacity to mimic the functional dynamics of natural muscle tissue. Image Credit: Cheng-Hui Li and Pengfei Zheng.

They accomplished self-assembly and microphase separation by carefully adjusting the intra- and intermolecular interactions of PCL and PFPE (such as dipole-dipole interactions) under regulated conditions, which inhibited the crystallization of PCL moiety.

Dr. Cheng-Hui Li led the research from the School of Chemistry and Chemical Engineering, Nanjing University, and Dr. Pengfei Zheng from the Children’s Hospital of Nanjing Medical University.

At room temperature and without an external force, the material maintains its high elasticity and low elastic modulus in an amorphous state. Under tensile stress, the amorphous polymer chains unfold, align, and reorient along the loading direction, increasing the material's toughness and tensile strength.

Additionally, the material exhibits exceptional resistance to tearing and punctures. PCL chains escape the amorphous areas to form chain-aligned microcrystalline structures during cyclic tensile deformation at high strains, giving the material training enhancement qualities similar to those of muscles.

Furthermore, the artificial muscle exhibits remarkable actuation performance and shape memory, with energy densities of 1450 J/kg and actuation strains of up to 600%. The material can reliably perform reversible contraction and extension motions over several heating and cooling cycles and lift objects weighing more than 5000 times its weight when thermally stimulated.

This artificial muscle combines low modulus and high toughness while successfully replicating the training enhancement and actuation functions of natural muscle, showing great potential in prosthetic actuators.

Dr. Cheng-Hui Li, School of Chemistry and Chemical Engineering, Nanjing University

The material is highly biocompatible, exhibits no cytotoxicity, and greatly stimulates myoblast development and differentiation, forming myotubes aligned with the material's stretching direction.

Following implantation, histological analyses showed that the substance promoted the growth of muscle tissue along the scaffold. Four weeks later, the regenerated muscle had a similar contractile force to normal rats and showed a well-organized structure and morphology. Additionally, increased angiogenesis, essential for muscle regeneration, is indicated by vascular regeneration as assessed by CD31 and α-SMA staining.

The exceptional elasticity, toughness, and softness of this artificial muscle allow it to flexibly interact with residual muscles. This enables rats to maintain daily activities after scaffold implantation without muscle atrophy or joint dysfunction caused by traditional surgical suturing or immobilization, significantly shortening the recovery period.

Dr. Pengfei Zheng, Children’s Hospital, Nanjing Medical University

This cutting-edge synthetic muscle material creates new opportunities for biomedical uses, especially in tissue engineering, regenerative medicine, and prosthetics.

Journal Reference:

Qiu, P.-F., et al. (2024) A soft, ultra-tough and multifunctional artificial muscle for volumetric muscle loss treatment. National Science Review. doi.org/10.1093/nsr/nwae422.