A collaborative effort between researchers at the Stanford Synchrotron Radiation Lightsource (SSRL) and the University of California, Davis has resulted in the development of a novel methodology for accelerating the discovery of single-atom catalysts, a highly promising emerging category of these indispensable substances. The study was published in Chemistry–Methods.

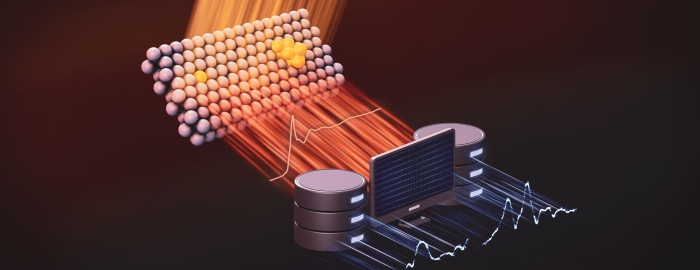

SLAC and University of California, Davis, researchers have developed software to determine more quantitative information about the active site of a single atom catalyst. MS-QuantEXAFS calculates the percentages of platinum atoms and platinum nanoparticles on a single atom catalyst, aiding researchers in the quest to relate structure to the catalyst activity. Image Credit: Greg Stewart/SLAC National Accelerator Laboratory

SLAC and University of California, Davis, researchers have developed software to determine more quantitative information about the active site of a single atom catalyst. MS-QuantEXAFS calculates the percentages of platinum atoms and platinum nanoparticles on a single atom catalyst, aiding researchers in the quest to relate structure to the catalyst activity. Image Credit: Greg Stewart/SLAC National Accelerator Laboratory

Catalysts have been unsung heroes in everyday life for decades. These workhorses, such as the yeast used to make bread and artificial catalysts for more effectively and sustainably converting raw materials into fuels, convert a starting material into a product or fuel with lower energy. Researchers need new techniques to better understand single-atom catalysts, a promising class of these useful substances.

More specifically, they are curious about how the catalyst's activity—that is, its ability to speed up chemical reactions—is impacted by the structure of the active sites, which are the places where chemical reactions occur.

In a significant advancement, a team from the University of California, Davis (UC Davis) and researchers from the Stanford Synchrotron Radiation Lightsource (SSRL) at the Department of Energy's SLAC National Accelerator Laboratory worked together to create a new software tool that, in comparison to existing techniques, can provide more quantitative details about the structure of the active sites in single-atom catalysts in a significantly shorter amount of time.

Typically, a catalyst stabilizes clusters of metal atoms, or metal nanoparticles, that are nanometers in size using an inert support. Atoms inside the nanoparticle are not used during catalysis; only the atoms on the surface serve as active sites. Single-atom catalysts, in which individual metal atoms are scattered onto the support, are a promising concept that researchers developed to optimize the use of each metal atom.

Researchers must comprehend the structure of the active sites to relate it to the activity when designing and developing these catalysts. As a case study for comparable single-atom catalysts, the team employed single platinum atoms stabilized on a magnesium oxide support to gain a better understanding of the structure.

The study, led by Rachita Rana (recent Ph.D. from UC Davis), employed extended X-ray absorption fine structure (EXAFS) spectroscopy to elucidate the average atomic environment around the active site, including the number and distances of neighboring atoms.

Before choosing the best fit, researchers typically assess 10 to 100 candidate structures using EXAFS data. Rather, Rana suggested automating the analysis process by fusing EXAFS with theoretical computations known as density functional theory. The structure of one type of atom - in this case, platinum atoms - was ascertained by the initial iteration of the program, QuantEXAFS.

Catalysts typically contain both single atoms and nanoparticles. By extending the functionality of QuantEXAFS, Rana was able to provide more precise information about the structure by calculating the fractions of these two forms.

MS-QuantEXAFS not only helps identify the active sites, but also quantifies the percentage of a specific site and automates the entire data analysis process. If you’re doing this manually, it typically could take you anywhere from a few days to months. With MS-QuantEXAFS, you could potentially do this analysis overnight on a local computer.

Rachita Rana, Ph.D., Study Lead Author, University of California, Davis

The group's next goal is to get MS QuantEXAFS ready and make it available to the scientific community.

This tool has a lot to offer to catalysis researchers.

Rachita Rana, Ph.D., Study Lead Author, University of California, Davis

Simon R. Bare, Study Co-Author and Distinguished Scientist at Stanford Synchrotron Radiation Lightsource, agrees adding that they also plan to include it in training classes, especially for the next generation of students.

This work was funded by the DOE Office of Science. DOE Office of Science user facilities include SSRL.

Journal Reference:

Rana, R., et al. (2024) Quantifying the Site Heterogeneities of Non-Uniform Catalysts Using QuantEXAFS. Chemistry–Methods. doi.org/10.1002/cmtd.202400020