The Perten Falling Number® System from PerkinElmer features the international standard method to determine alpha-amylase activity in grain and flour. The instrument quantifies the alpha-amylase enzyme activity in grains and flour to optimize flour enzyme activity, identify sprout damage and ensure the quality of traded grain.

Alpha-amylase activity is a vital parameter to ensure the final product quality of bread, malt pasta and noodles. The Falling Number system benefits any users who handle wheat, barley, sorghum or rye used mainly for these applications.

The method is approved by international bodies like the ISO, ICC, ASBC and CGA in the form of the following standards: ISO/No. ISO/DIS 3093 (1974), ICC/No. 107/1 (1968), ASBC Barley 12-A, and AACC/No. 56-81.03 (1972).

World Standard — The Perten Falling Number models are the only certified instruments for Falling Number testing in compliance with international standards: ISO/DIS 3093, AACC/No. 56-81.03, and ICC/No. 107/1.

Applications

Measuring the alpha-amylase activity is very important for many reasons. Rainy and adverse weather conditions at the time of harvest can lead to sprouting. Sprouting causes the development of the alpha-amylase enzyme. Alpha-amylase activity has a direct effect on the quality of bread and pasta and has an adverse impact on the malting process. Sprouted grain as low as 5% combined with 95% sound grain can make the entire mixture unsuitable.

The end-users of wheat, barley, and rye are affected if the grain is sprout-damaged and they must monitor the ingredients they buy. To avoid sprout-damaged grain from reaching the production chain, grain receivals and farmers should test the grain at the time of harvest, as well as when it is delivered.

Falling Number in Grain Trade

Considerable sprout damage could occur in years with rainy weather conditions at the time of harvest. Each truckload of grain in such years ought to be tested at the grain receivals before they are unloaded and segregated to various silo bins to prevent the mixing loads of sound grain with sprout-damaged grain.

Sprout-damaged grain can be used to prepare animal feed or for other non-baking purposes like biofuel. The segregation is crucial because an unregulated mixing of even a few percent of highly sprouted grain with sound grain can render the entire mixture unacceptable for making bread or other end-product purposes. Moreover, segregation enables a careful blending of grains to fulfill FN specifications specifically at the flour mill.

The Falling Number value can differ from 62 seconds for heavily sprouted grain with too much enzyme activity to well above 400 seconds for grains received from dry, warm areas. The accurate limits for segregation differ between various markets or countries and based on the end-use purpose of the grain.

The limit for the intervention of bread, or wheat in the European Union (EU) is a minimum Falling Number of 220 seconds. Segregation limits at 250, 300, and even 350 seconds are often used, for instance, by exporting countries for wheat or durum wheat. These limits are generally lower for rye, with segregation below or above the range of 110–140 seconds.

Since the quality of sprout-damaged grain is affected, the FN value is used in price control to pay traders or farmers both in national and international trade across the globe and to verify trade contract quality specifications. A 10%–30% lower price could be given to typically damaged wheat, leading to considerable economic losses to the grain trader or farmer.

Falling Number in Flour Milling and Baking

Proper baking requires a specific amount of alpha-amylase. The alpha-amylase disintegrates starches to make sugars that help fuel the fermentation process. The amount of enzyme in the flour could have a direct impact on the quality of produced bread.

The right alpha-amylase activity ensures a high volume bread with a soft and firm texture (FN = 250). Too much alpha-amylase activity can lead to a sticky bread crumb and low volume (FN = 62).

A very low alpha-amylase activity may lead to a dry bread crumb with reduced volume (FN = 400). The FN value is inversely related to the alpha-amylase activity, that is, the higher the alpha-amylase activity, the lower the FN value, and vice-versa.

The FN value can be used by millers to produce products with specific or preferred FN values. They may mix flours of different FN values to make a product with a particular amylase activity. They can even add malt to adjust the value in a similar way.

The precise FN number value preferred depends on the kind of product to be made. Bread flours tend to have various FN values than those of cracker flours. The FN value can be used by bakers to inform their suppliers of the kind of product they need for their particular end-product.

Moreover, bakers have the option of controlling their flours similar to the miller. However, by dictating the miller to supply a particular product, a baker can achieve a consistent product and would not need to adjust this specific aspect of the baking process.

The FN value can be used by quality control personnel as a quality control tool to ensure the consistency of both incoming and outgoing products. It is another crucial tool to save time and money.

Falling Number in Pasta and Noodle Manufacturing

It is hard to produce noodles from flour that has a low Falling Number because it presents dough handling and cutting problems and leads to sticking of product to machinery. It also leads to an off-color end consumer product, which tends to be sticky once it is boiled. The use of flour with the correct Falling Number® will lead to savings by improved processing and an end product of higher quality.

Falling Number in Malting

A high germination in malting barley requires sound, viable grains. Various studies have demonstrated that barley pre-germinated in the field has a lower ability to germinate at the time of the malting process. This results in high levels of beta-glucan in the wort. Barley with a low degree of pre-germination gets affected.

Storage reduces the ability to further germinate, and barley with suitable germination at harvest could show germinations much lower than the often required 95% only months later. Slight pre-germination cannot be detected by visual inspection. It can be done only by measuring the alpha-amylase activity.

The Falling Number analysis helps prevent the purchase of pre-germinated barley through acceptance testing at the barley intake. The method is fast and identifies whether the barley is pre-germinated within 5 minutes.

- FN < 250 indicates pre-germinated barley — risk of poor germination, more tests are required

- FN > 250 indicates sound barley and batch fine for intake

Models

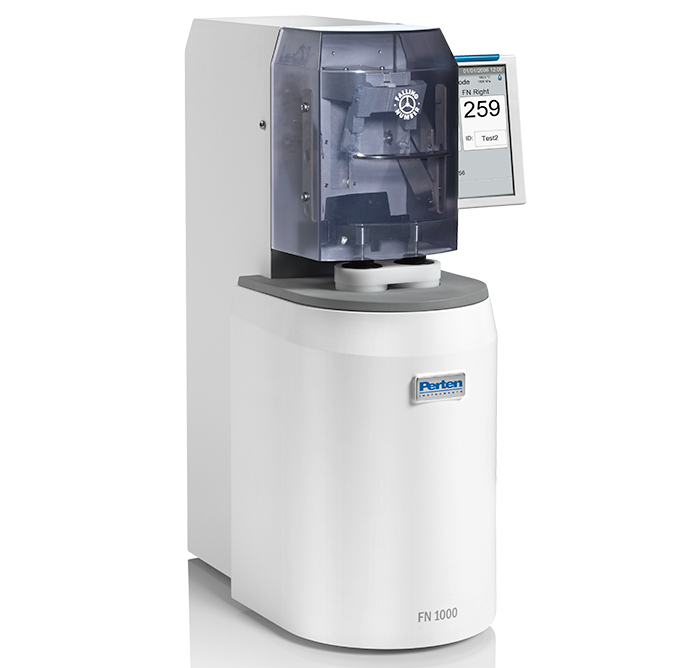

Falling Number 1000

FN 1000 is the latest and most advanced Falling Number instrument model that delivers various new advantages and enhanced features. It is a dual analysis system ideal for anyone who needs high capacity and reliable analysis.

Image Credit: PerkinElmer Food Safety and Quality

Falling Number 1310

The FN 1310 is PerkinElmer’s basic model that enables users to purchase an original Perten system at an optimum price. Designed for rapid, convenient operation of the Falling Number test, the FN 1310 is an automatic single analysis system. The instrument has been designed and developed to high quality standards, thereby delivering a high return on investment for several years of trouble-free operation.

Image Credit: PerkinElmer Food Safety and Quality