Researchers from North Carolina State University have been working on novel techniques to apply industrial semiconductor processes to substrates, such as fabrics and textiles, to “weave together” multifunctional materials.

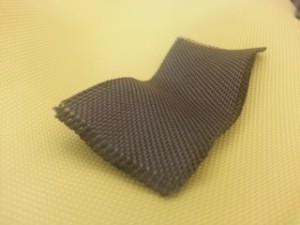

Tungsten-coated Kevlar with a Kevlar (uncoated) background.

Tungsten-coated Kevlar with a Kevlar (uncoated) background.

Atomic layer deposition (ALD) was used to perform the “weaving”. ALD is a method generally used in to manufacture memory and logic systems.

Using ALD, the researchers were able to create highly conductive and robust yarns from tungsten metal on Kevlar also known as body armour material.

The researchers specifically chose the ALD method as it allowed highly compatible thin films to be deposited on non-planar surfaces with a thickness precision of nanometres.

It was ensured that the yarn’s complete surface comprising around 600 fibers, the diameter of each being 12µm, was properly coated.

The ALD method is a cyclical procedure in which the substrate's surface is first exposed to a gas-phase chemical such as tungsten hexafluoride (WF6) after which, any unreacted material is removed.

Next, the surface is exposed to another gas-phase chemical such as silane (SiH4) before any unreacted material is again removed. The reaction between the two chemicals results in tungsten production by the time the cycle ends.

The ALD process is self-limited and for every cycle one atomic layer gets deposited. In this experiment it was around 5.5 Angstroms per cycle. The cycles can be repeated in order to create a specific thickness. Another key advantage of the ALD method is that it takes place in the gaseous phase therefore it does not need solution processing and it is more sustainable.

By performing ALD of tungsten on Kevlar, yarns with exceptional features such as very high flexibility and high conductive level of nearly 2,000 S/cm (Siemens per centimetre) were created. It was also observed that the yarns retained around 90% of their initial prior-to-coating tensile strength.

"Introducing well-established processes from one area into a completely new field can lead to some very interesting and useful results"

Sarah Atanasov, a Ph.D. Biomolecular Engineering Department at North Carolina State University.

The North Carolina research team believes their tungsten-on-Kevlar yarns can be used for antistatic erosion-resistant fabrics for automated and space technologies, as well as for multifunctional protective electronics for electromagnetic shielding and communications.

Their discoveries will be presented at the AVS 61st International Symposium & Exhibition, in Baltimore, Maryland, between 9th and 14th November.