Aerospace specialist Airframe Designs has joined a national industry body to help lead the development of additive manufacturing and 3D printing in the UK.

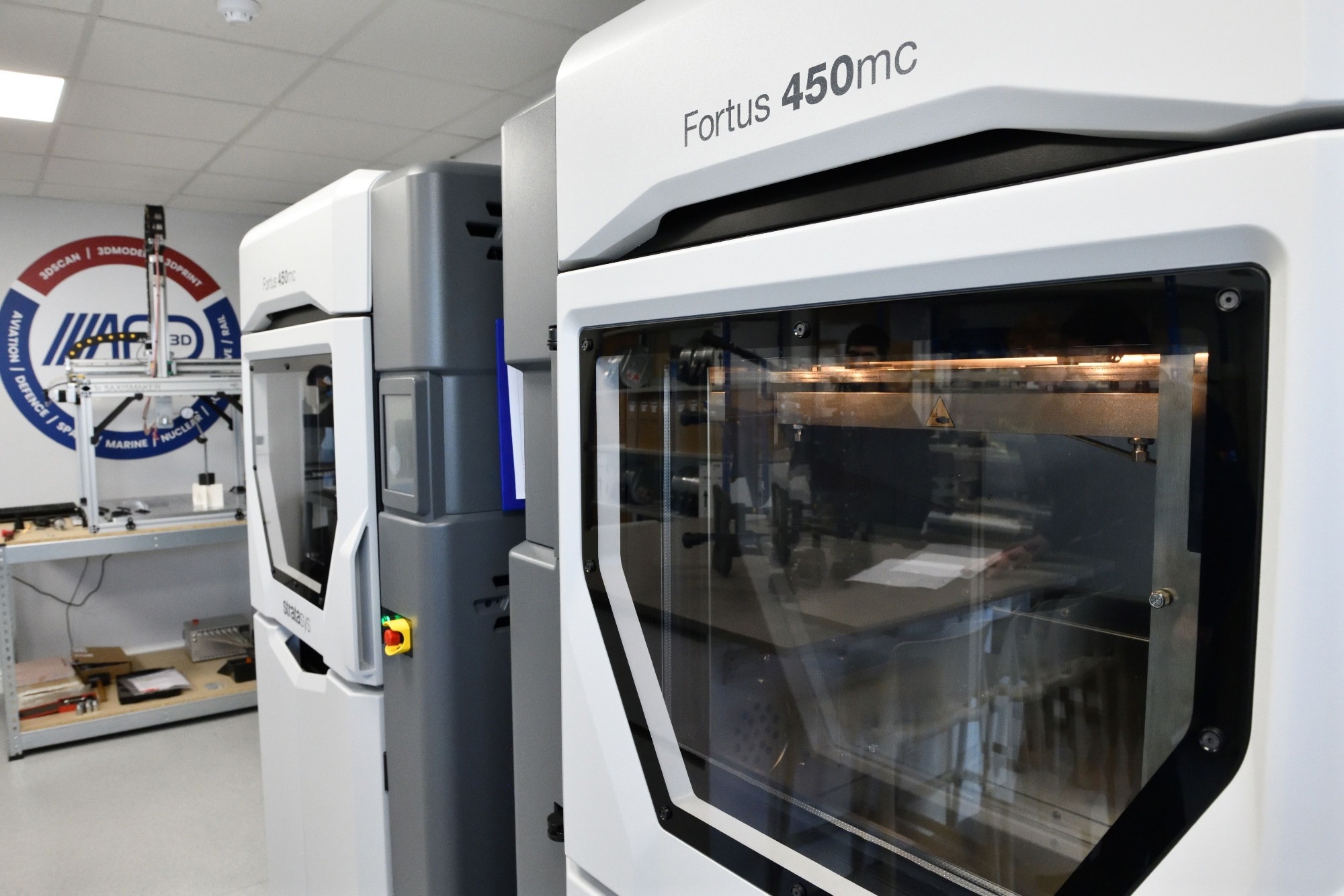

Image Credit: Airframe Designs

The company has become a member of Additive Manufacturing UK (AMUK) whose aim is to establish the UK as a world leader in the development and adoption of additive and 3D printing technology.

Jerrod Hartley, CEO of Airframe Designs, said: “Joining the lead industry organisation will help raise awareness of the benefits of additive manufacturing technology and our own engineering excellence.

“There is a revolution happening in UK manufacturing with the adoption of additive manufacturing and we want to help lead and build on these opportunities.

“This technology enables us to produce lightweight, highly accurate, and robust airframe parts and tooling which are delivered at pace, whilst also helping to reduce carbon emissions and achieve Net Zero goals by 2050.”

As part of its commitment to the development of additive manufacturing, Airframe Designs has recently invested in a second 3D printing machine, a state-of-the-art Stratasys Fortus 450, a new five-axis milling machine and new sophisticated resin printing technology to offer increased capability and quality of parts and tools for its increasing customer base.

The AMUK has become part of the wider Manufacturing Technologies Association (MTA) cluster to lead the industry as it becomes an increasingly important part of the manufacturing drive.

The services offered by Airframe Designs meet the demand from the aviation and defence sectors to create new parts or re-engineer obsolete parts in an agile, cost-effective, and sustainable manner.

With polymer additive manufacturing technology, combined with 3D scanning and 3D modelling, it is possible to deliver creative solutions to complex engineering problems in the aviation and defence part market, including solutions for airframe tooling. This technology can also be adapted for other industries including space, nuclear, motorsport and rail.

Recent projects undertaken by Airframe Designs include the design and manufacture of several 3D printed tooling fixtures to aid the installation of external sensors onto the fuselage of a special mission military aircraft and the integration of new systems into heavy lift drone platforms.

The company has also been responsible for the conceptual design at a platform level for new uncrewed air-systems, test rig and tooling for electric vehicle propulsion systems and most recently the design and analysis of operator consoles for a special mission aircraft.

Source: https://airframedesigns.com/