AZoM spoke to Kevin Fernandes from Endress+Hauser about the significance of online Raman spectroscopy in industrial processes, as well as its potential role in emerging industries.

Please can you introduce yourself and your professional background within analytical chemistry, as well as your current role at Endress+Hauser?

I’ve always enjoyed working in the lab right from school. I started working for Thames Water in 1977 as a lab assistant on water treatment works, and then worked in pharmaceutical research with GlaxoSmithKline. During this time, I also studied part-time for the Ordinary National Certificate in sciences through to a degree level.

It was at this point that I moved into the commercial world as a sales engineer for Varian Chromatography Instruments and became a product specialist for a range of consumables, helping customers with their method development protocols.

Prior to joining Endress+Hauser, I held several business development roles that included liquid handling, supercritical fluid chromatography, high throughput synthesis chemistry, and the application of electrochemistry to High-Performance Liquid Chromatography (HPLC).

My current role at Endress+Hauser covers the UK as a process analysis sales engineer for optical spectroscopy instrumentation. This includes sales and support of Raman Spectroscopy and Tunable Diode Absorption Laser (TDLAS) instruments.

Endress+Hauser is a world-leading provider of measurement instrumentation and solutions for industrial process engineering. How essential is measurement instrumentation to industrial chemical processes?

It is vitally important, as analytical technologies are the window into the process. Online analysis as opposed to offline or remote facilitate rapid decisions and can contribute significantly to process efficiency, better utilization of plant assets, and ultimately, the bottom line.

Image Credit: Forance/Shutterstock.com

Could you please provide an overview of what Raman spectroscopy is as well as its various industrial applications?

Raman spectroscopy is a light scattering technique. Raman utilizes a high-intensity light source from a laser, usually supplied by a fiber optic cable to the sample of interest. Most of the scattered light will be at the same wavelength as the laser—this is known as Rayleigh scatter, and photons of this type will be filtered off.

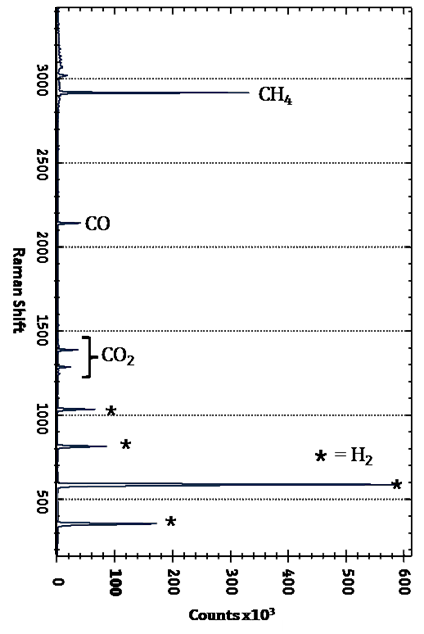

However, some of the backscattered light will change wavelength or color. This is called the Raman scatter and this will represent what we want to measure. The Raman spectrum, as such, can show several peaks demonstrating their intensity and wavelength position. Peaks in a Raman spectrum correspond to a molecular vibration; for example, these can be C-C, C=C, N-O.

Raman Spectra of a simple Gas Mixture

Raman spectroscopy allows online optical analysis to bridge the gap between lab and process. How is this possible and in what ways is this advantageous?

Lab to process is very much a mantra of Endress+Hauser. What this means is that analytical methods developed in the lab can be seamlessly integrated into the process and become an integral part of it rather than a remote or discrete one - the lab comes to the sample. To get this set up, the introduction of a Raman light source just needs a probe connected to the process in question—the probe itself can be changed to accommodate many different sample types, for example gases, liquids, slurries, and powders.

The Raman hardware is robust, and all the software is integrated so there are no requirements for additional computers. Data transfer to the most commonly used control systems is easy due to OPC and Modbus protocol outputs. When the process is monitored, online results are continuous and in real time, which allows for changes to the process to be made on the fly, meaning there are no delays waiting for results to come back from the laboratory.

To put this into context, applying Raman spectroscopy to advanced bioprocesses would generate a control saving of around £5,000 on a typical 6,000 litre vessel by not having to include offline analysis. Furthermore, the risk of compromising bioreactor sterility is also removed by not having to sample the vessel periodically and invasively. Chemometric models developed in the lab also allow for convenient method transfer and allow the scaling up of process levels.

You will be conducting a talk on Raman spectroscopy at the 2022 ChemUK conference in May. What can visitors expect from your presentation?

My talk will provide a quick overview of the Raman technique and technology, focusing on some of the applications that we have developed at Endress+Hauser and how these have been implemented into our markets such as the manufacturing of chemicals, oil and gas production, and bio/pharmaceutical production.

Click Here to Sign Up for ChemUK 2022

What role will Raman spectroscopy play in emerging industries such as clean energy and green chemistry, and what benefits will implementing this analytical technique have?

Nice question! Endress+Hauser Raman is already playing a part in monitoring the purity of green and blue hydrogen etc. from processes such as electrolysis and steam reformation of methane. Raman has also been integrated with other Endress+Hauser instrumentation to provide a complete solution for this very important application. In addition to this, Endress+Hauser TDLAS instrumentation is being used to measure compounds such as moisture and carbon dioxide in hydrogen streams and carbon capture projects.

What does the future of measurement instrumentation look like to you? Do you expect this technology to evolve much in the years to come?

The measurement aspect of the process will increasingly become more integrated, and although the instrumentation footprint in a plant will get smaller, it will become increasingly more information-rich.

After the halt of many in-person conferences due to the ongoing COVID-19 pandemic, how important are conferences like ChemUK for developing and sharing ideas within industries?

Online platforms like Teams and Zoom are still great for pulling people together, particularly at short notice. However, nothing in my opinion beats having face to face meetings to conduct business. To that end, conferences like ChemUK are invaluable to provide those platforms.

Further Information:

https://www.endress.com/en/endress-hauser-group/product-center-competencies/optical-analysis

www.uk.endress.com

www.rsc.org

Process Raman Spectroscopy Selected Application Notes

Chemical Process

- Monitoring polymerization reactions.

- In-line monitoring of ethylene vinyl acetate Copolymer with Raman spectroscopy

- Raman spectroscopy in the chemical industry.

Oil and Gas

- Process Raman Spectroscopy for custody transfer operations of ship to ship and ship to shore Liquefied Natural Gas (LNG) cargoes.

Life Science

- Advanced process and product control in fermentations. Raman spectroscopy for composition analysis in a lab or process

- Raman spectroscopy For bioprocess applications

- Raman spectroscopy simultaneously measures several parameters in-situ real-time monitoring bioprocess.

About Kevin Fernandes

I’m currently employed as a Process Sales Engineer by Endress+Hauser Ltd in the UK, providing sales support for our laser-based spectroscopy instrumentation which includes Raman and Tunable Diode Laser Spectroscopy Instrumentation.

I’m currently employed as a Process Sales Engineer by Endress+Hauser Ltd in the UK, providing sales support for our laser-based spectroscopy instrumentation which includes Raman and Tunable Diode Laser Spectroscopy Instrumentation.

I’m very privileged to have a career in the field of natural sciences, from the lab bench to the commercial world where I now reside. Career highlights include the development and bringing to market of many new and innovative technologies in the analytical world. My old chemistry teacher told me: “you spend a long time working, so do something you are going to enjoy.” Wise words that still hold true today.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.