Gear designers across all industries are under pressure to achieve improved reliability, greater efficiency, reduced vibration, noise and harshness (NVH), and at the same time aim to achieve smaller components and minimize overall system costs when compared to precision metal gears.

VICTREX PEEK polymers (Figure 1) are increasingly used as an alternative solution to conventional metal components in a variety of applications, including high performance gear applications.

Figure 1. VICTREX PEEK Polymers

VICTREX PEEK Polymers in Gear Applications

Although many enterprises still hinge on metal gears, other leading players are using new materials for cost and performance benefits. Many of these advances already leverage the benefits of highly versatile VICTREX PEEK polymers.

Challenging mechanical demands for gear wheels can be perfectly met with VICTREX PEEK polymers, thanks to their superior mechanical and temperature or chemical resistance properties.

Figure 2. VICTREX PEEK gear

As a true alternative solution to metals, VICTREX PEEK delivers superior performance under extreme conditions and offers key benefits across all phases of the production process.

The key benefits of gears made of VICTREX PEEK over metal gears:

- Up to 70% weight reduction

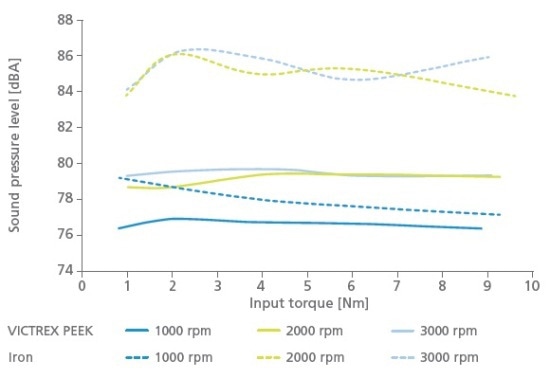

- Up to 50% (3dB) noise reduction (Figure 3)

- Up to 80% reduced moment of inertia

Figure 3. Sound level comparison between iron and VICTREX PEEK gears at various loads and speeds

VICTREX PEEK polymers maintain mechanical properties at high temperatures and in adverse chemicals and moisture, making them the material of choice over other gear materials to the industry demands for extended service life in more challenging environments.

Victrex has created a new PEEK for use in gear applications improving the already proven properties of VICTREX PEEK 450G to achieve extended service life in lubricated applications.

The new VICTREX PEEK imparts the technical and economical benefits of PEEK to even the most challenging gear applications, such as pumps in medical devices, high-speed printers and copiers; and automotive engines and transmissions.

Download the full Victrex Gear Guide for more information.

Reliable and Efficient Gear Solutions

VICTREX PEEK Polymers used in reliable and efficient gear solutions:

- Significant weight reduction lowers energy consumption

- Extended design options and a high damping capacity lead to high comfort, less vibration and noise

- No strength loss or swelling due to moisture absorption

- Reduced moment of inertia leads to improved responsiveness

- High corrosion resistance, very low friction and wear, and minimal lubrication extend lifetime and service intervals

- Superior resistance to oil particle contamination, chemicals and all known automotive fluids enables the material to be used in the most challenging environments

Advantages of VICTREX PEEK Polymers over Metals

- Compared to precision metal gears, lower investment for mass production owing to injection-molding production process

- No need for secondary machining, hardening or finishing operations

- Possibility of hybrid technology with composites, metals and other plastics

- Greater design freedom and faster production ramp-up

This information has been sourced, reviewed and adapted from materials provided by Victrex.

For more information, please download the full report from Victrex.