By Taha KhanReviewed by Lexie CornerSep 3 2024

By Taha KhanReviewed by Lexie CornerSep 3 2024

Composite materials are created by combining two or more distinct materials to produce a new material that surpasses the characteristics of its individual components. These materials are widely used in modern industries, offering stronger, lighter, and more durable alternatives to traditional materials.1 This article explores the significance of composite materials and their applications across various sectors.

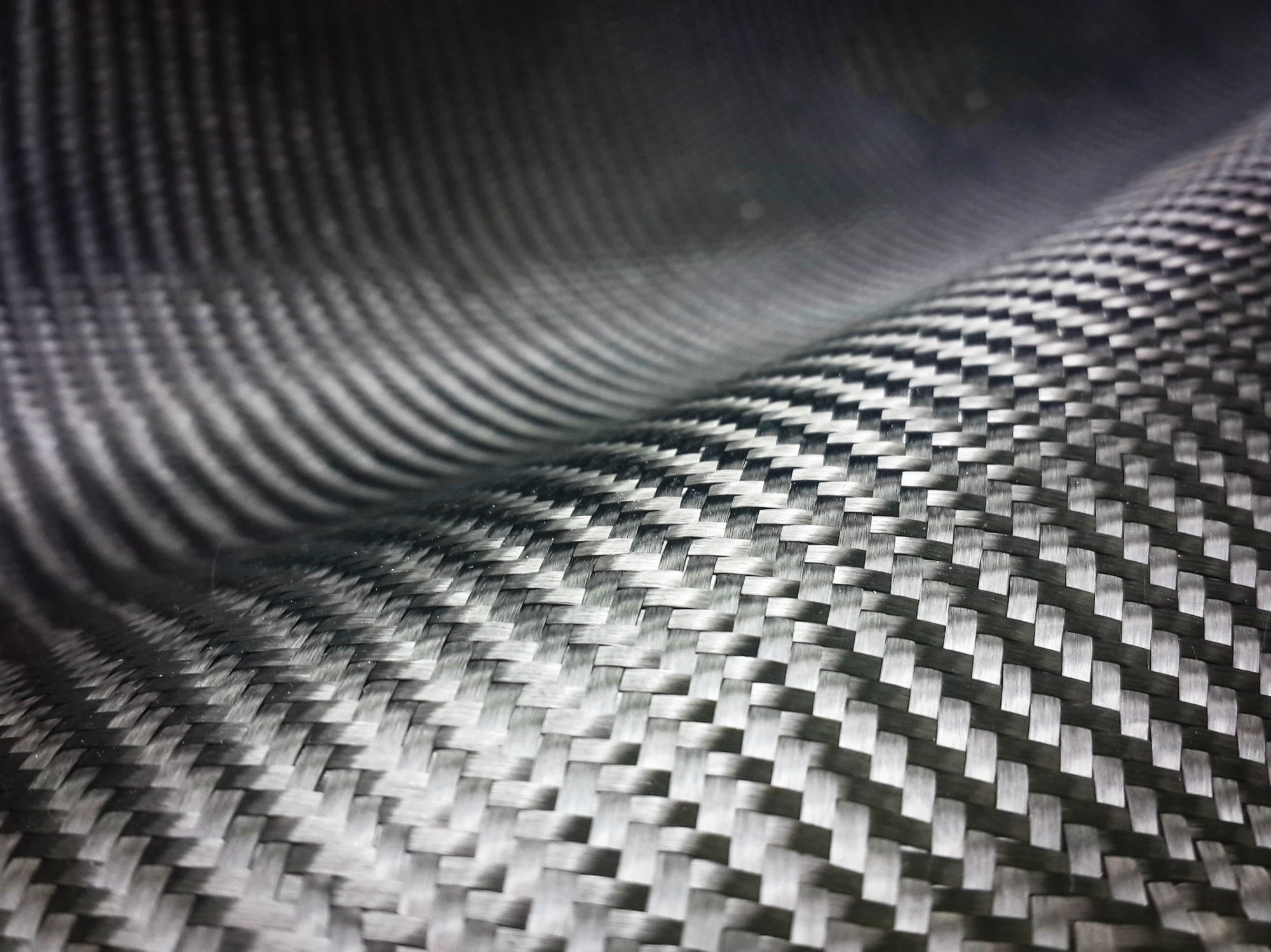

Image Credit: Composite_Carbonman/Shutterstock.com

How Are Composites Produced?

Composite materials are engineered by fusing different materials, typically consisting of a matrix (a polymer, metal, or ceramic) and a reinforcement (such as fibers, particles, or flakes) that provides strength and stiffness. The interaction between these components results in composite materials with superior mechanical and physical properties compared to their individual constituents.1

The manufacturing of composites involves various processes, depending on the materials used and the desired properties of the final product. Typically, the process starts with selecting the appropriate matrix and reinforcement, which are then combined using methods such as layering, molding, or extrusion.

For example, in the layering process, reinforcement materials are stacked in layers, with each layer bonded by the matrix to produce composites like carbon fiber sheets.1, 2

Molding involves placing the reinforcement within a mold and injecting or pouring the matrix material around it to create complex shapes and structures, such as fiberglass components.

Extrusion, on the other hand, pushes a mixture of the matrix and reinforcement materials through a shaped die to produce long, continuous composite products like pipes and rods.

Each process is chosen based on the specific application and desired properties of the composite material, such as strength, weight, and flexibility.1, 2

Types of Composites and their Properties

Composite materials offer numerous advantages over traditional materials, as their properties can be tailored to specific applications.1, 3

The reinforcement in composites significantly enhances their strength and rigidity, making them ideal for structural applications that require robust performance. Meanwhile, the matrix material provides protection against environmental factors like moisture, chemicals, and temperature changes, resulting in a highly durable material.1, 3

Fiberglass Composites

Fiberglass is a composite material made of glass fibers embedded in a polymer matrix and is widely valued for its strength, lightweight characteristics, and corrosion resistance. Its excellent electrical insulation properties make it a preferred material in electrical and electronic applications.4

Carbon Fiber Composites

Carbon fiber composites are extensively used in high-performance applications due to their remarkable strength and lightness. These composites maintain their mechanical properties over time, even under cyclic loading, making them durable in demanding environments.

Although significantly stronger, stiffer, and lighter than steel or aluminum, carbon fiber composites are also resistant to corrosion and many chemicals, making them ideal for harsh environments.5

Concrete

Concrete, one of the most common and oldest composite materials, is extensively used in construction for its durability and versatility.6 It is created by combining cement as the matrix with aggregates like sand and gravel as reinforcements, allowing it to be molded into various shapes. When mixed with water, the concrete hardens and gains strength over time.

Concrete has several valuable properties, including resistance to weathering, erosion, and chemicals. It also has high thermal mass, allowing it to absorb and slowly release heat, contributing to building energy efficiency. While concrete is strong in compression, it is weak in tension and is often reinforced with steel bars to enhance its tensile strength.7, 8

Kevlar Composites

Kevlar is a high-strength synthetic fiber known for its excellent tensile strength, impact resistance, fatigue resistance, and thermal stability. Kevlar composites are typically made by combining Kevlar with resins such as epoxy or polyester, which bind the fibers together, distribute loads, and protect the fibers from environmental damage.

The orientation of Kevlar fibers within the composite is crucial, and unidirectional, bidirectional, or woven patterns can be used to tailor the mechanical properties, such as strength and stiffness, to specific needs.9

Ceramic Matrix Composites

Ceramic matrix composites (CMCs) are advanced materials made by embedding fibers within a ceramic matrix. Traditional ceramics are brittle; CMCs are engineered to overcome this limitation by incorporating fibers that enhance their toughness, making them more resistant to cracking and damage under stress.

Key properties of CMCs include excellent thermal shock resistance, low density compared to metals, and resistance to oxidation and corrosion, making them ideal for applications where both high mechanical strength and thermal performance are critical.10

Metal Matrix Composites

Metal matrix composites (MMCs) combine metal matrices, such as aluminum, with reinforcements like ceramic or carbon fibers. These composites provide enhanced stiffness and wear resistance while maintaining the inherent ductility and thermal conductivity of the metal matrix.

MMCs are used in applications requiring high-performance materials, such as automotive brake rotors, aerospace structural components, and heat sinks in electronics.11

Applications of Composite Materials

Composite materials play a crucial role in various industries. In the renewable energy sector, they are particularly important in the construction of wind turbine blades. Their strength and lightweight properties allow for longer, more efficient blades that capture more energy.12 In the marine industry, composites are ideal for boat hulls, decks, and other structural components due to their corrosion resistance and lightweight nature.1

One of the most notable applications of composite materials is in the aerospace and automotive industries, where weight reduction is critical for improving fuel efficiency and performance.13

Composite materials, particularly carbon fiber, are extensively used in aircraft structures, including wings, fuselages, and interior components. Similarly, fiberglass and carbon fiber composites are used in everything from body panels to interior components, enhancing vehicle performance and safety.13

Emerging Trends and Future Directions in Composites

In a recent study, researchers explored the potential of enhancing kenaf fiber-reinforced epoxy composites for automotive applications by incorporating graphene nanoplatelets (GNPs). The study focused on improving the mechanical properties of these composites, which are crucial for automotive parts like dashboards and interior panels.

By introducing 0.2 wt% GNPs, significant improvements were achieved in tensile and flexural strength, interlaminar shear strength, and fracture toughness. These advancements are important for developing lightweight, durable composite materials suitable for automotive applications, offering both performance and environmental benefits.14

Composite materials have become the backbone of modern engineering and manufacturing, but their true potential is yet to be fully realized. Continuous research and development will lead to the introduction of novel materials with even better characteristics, further impacting modern industries.

More from AZoM: Fiber-Reinforced Thermoplastics: Applications, Trends, and Innovations

References and Further Reading

- Abramovich, H. (2017). Introduction to composite materials. Composite and Nanocomposite Materials - From Knowledge to Industrial Applications. https://doi.org/10.5772/intechopen.91285

- Hasan, M., Zhao, J., Jiang, Z. (2019). Micromanufacturing of composite materials: a review. International Journal of Extreme Manufacturing. https://doi.org/10.1088/2631-7990/ab0f74

- Nagavally, RR. (2017). Composite materials-history, types, fabrication techniques, advantages, and applications. Int. J. Mech. Prod. Eng. https://www.digitalxplore.org/up_proc/pdf/240-146959633425-30.pdf

- Klosterman, D., Browning, C., Hakim, I., Lach, K. (2021). Investigation of various techniques for controlled void formation in fiberglass/epoxy composites. Journal of Composite Materials. https://doi.org/10.1177/0021998320952517

- Sayam, A., et al. (2022). A review on carbon fiber-reinforced hierarchical composites: mechanical performance, manufacturing process, structural applications, and allied challenges. Carbon. doi.org/10.1007/s42823-022-00358-2

- Bolzoni, F., Brenna, A., Ormellese, M. (2022). Recent advances in the use of inhibitors to prevent chloride-induced corrosion in reinforced concrete. Cement and Concrete Research. doi.org/10.1016/j.cemconres.2022.106719

- Important Things to Know Concrete 101. [Online] Concrete Supply Co. Available at: https://concretesupplyco.com/homeowner-resources/ (Accessed on 24 August 2024)

- Shafigh, P., Asadi, I., & Mahyuddin, N. B. (2018). Concrete as a thermal mass material for building applications-A review. Journal of Building Engineering. https://doi.org/10.1016/j.jobe.2018.04.021

- Singh, T. J., & Samanta, S. (2015). Characterization of Kevlar fiber and its composites: a review. Materials Today: Proceedings. https://doi.org/10.1016/j.matpr.2015.07.057

- Chawla, K. K., & Chawla, K. K. (2019). Ceramic matrix composites. Composite Materials: Science and Engineering. https://doi.org/10.1007/978-3-030-28983-6_7

- Singh, B., et al. (2023). A future prospects and current scenario of aluminium metal matrix composites characteristics. Alexandria Engineering Journal. https://doi.org/10.1016/j.aej.2023.06.028

- Murray, R.E., et al. (2021). Structural validation of a thermoplastic composite wind turbine blade with comparison to a thermoset composite blade. Renewable Energy. doi.org/10.1016/j.renene.2020.10.040

- Gebrehiwet, L., Abate, E., Negussie, Y., Teklehaymanot, T., Abeselom, E. (2023). Application of composite materials in aerospace & automotive industry. International Journal of Advances in Engineering and Management (IJAEM). https://www.researchgate.net/profile/Lijalem-Gebrehiwet/publication/369201797_Application_Of_Composite_Materials_In_Aerospace_Automotive_IndustryReview/links/64100c3292cfd54f84fb4197/Application-Of-Composite-Materials-In-Aerospace-Automotive-IndustryReview.pdf

- Malik, K., Ahmad, F., Dawood, M. S., Islam, M. S., Ali, S., Raza, A., Shahed, C. A. (2024). Mechanical property enhancement of graphene-kenaf-epoxy multiphase composites for automotive applications. Composites Part A: Applied Science and Manufacturing. https://doi.org/10.1016/j.compositesa.2023.107916

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.