Magnetic-field induced reorientation, or the magnetic shape memory effect, is defined as 'the magnetic-field-induced rearrangement of (ferromagnetic) twinned martensite microstructure along with a large macroscopic deformation'.

Properties of Magnetic Shape Memory Alloys

The patented NiMnGa single crystal Magnetic Shape Memory material from Goodfellow has some incredibly innovative properties, including the following:

- Magnetic shape memory effect of up to 6% elongation in a magnetic field

- It exhibits inverse magnetostrictive effect or Villari

- It shows shape memory alloy effect with a shape change caused by applying a magnetic field as well as a shape change is caused by temperature

- If the element is completely compressed or elongated, a change in resistance occurs

- Exhibits controlled spring properties

The properties are also provided in the table below:

| Material |

NiMnGa single Crystal |

| Elongation in Magnetic Field |

Up to 6%, typically 3 to 5% |

| Response |

Up to 1 to 2 kHz |

| Force Density |

About 2 MPa |

| Work Output (force x stroke) |

Max 100 kJ/m3 |

| Fatigue Life |

Several hundred million cycles |

| Magnetic Field |

<0.8T |

| Upper Temperature Limit |

Transformation martensite to austenite 70°C |

| Curie Temperature |

95-105°C |

Applications

Actuators

The magnetic shape memory effect can be used for designing actuators where the element elongates based on the presence of a magnetic field. The elongation can be reversed fully either by the application of a magnetic field at 90° to the original field, or more effectively by use of a spring. The change in shape is very quick and cycle times of 1 to 2 kHz have been shown. During fatigue life testing several million cycles have been achieved.

These materials cannot achieve the frequency of piezo-based materials or magnetostrictive materials, however they offer much higher strain outputs (typically 10 to 100 times more). They also offer higher energy density typically up to 100kJm-3 compared to 14 to 30kJm-3 for magnetostrictive materials and 0.8 to 2kJm-3 for piezo-based materials.

Figure 1. A laboratory-based actuator with return spring

Breaker Switch/Fuse

The thermal shape memory property whereby the material elongates more above 70°C can be used as a safety cut-out. If a safe working temperature is exceeded, there is further extension cutting the magnetic field generation. This additional elongation can be reversed fully and below 70°C, normal functioning of the actuator is observed.

Energy Harvesters

The elongation or compression of the material causes it to change any magnetic field in which it is placed, known as variable magnetic permeability under varying stress, which can be used for harvesting vibrational energy. Possible uses include battery charging in environments where it is difficult to gain access to the batteries for replacement.

Vibration Dampers

The same properties used to create energy harvesters can also be used to dampen mechanical vibration.

Sensors

Using the material’s properties, it is possible to construct speed sensors as well as distance, strain and magnetic field detectors.

Availability

In order to minimize the magnetic energy required to elongate the material, a thin, wide cross-section is preferred, and as the elongation is a multiple of the length, a comparatively long strip is also preferred.

Therefore Goodfellow is offering this material in the following dimensions:

- 1Tx 2.5W x 20L in mm

- 1T x 5Wx 20L in mm

- 2T x 5W x 20L in mm

These are the company’s standard dimensions, but other dimensions are available on request. Presently the maximum single crystal size is 18DX30L in mm. Special techniques are used to cut smaller pieces from within the above dimensions to preserve material performance.

Fast Response to Control Signal

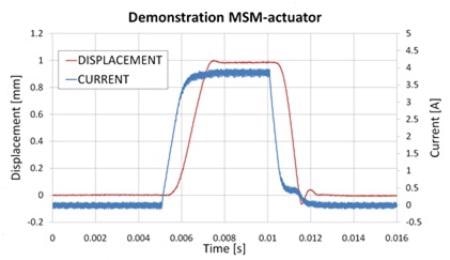

The response of the shape memory alloy to the control signal is shown in Figure 2.

Figure 2.

Magnetic field/strain

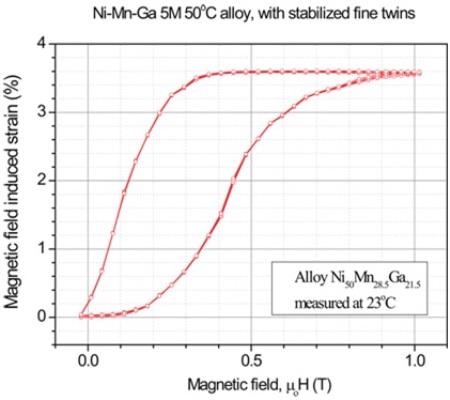

The developed strain depends on surface treatment. The following graph shown in Figure 3 is an example.

Figure 3.

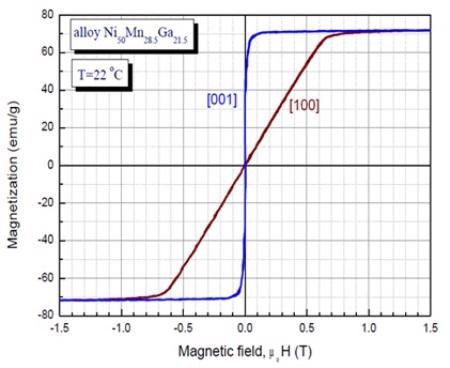

Magnetization when pressed/elongated

Figure 4.

Comparison with other materials

Comparison with other materials is shown in the Table.

| Material |

Strain |

Frequency |

Energy Density |

| Magnetic Shape Memory Material |

<6% |

<2 kHz |

<100 kJm-3 |

| (Thermal) Shape Memory Alloy |

<8% |

<3 Hz |

10,000 kJm-3 |

| Magnetostrictive Materials |

0.14 – 0.2% |

100s kHz |

14 – 30 kJm-3 |

| Piezo Materials |

0.04 – 0.07% |

100s kHz |

0.8 – 2.0 kJm-3 |

About Goodfellow

Goodfellow supplies metals, ceramics and other materials to meet the research, development and specialist production requirements of science and industry worldwide.

The Goodfellow group consists of four companies. The main administration, research laboratories and workshops are located at the Company's headquarters in Cambridge, England. The subsidiary offices in America, France and Germany provide an additional service.