Life Cycle Assessment (LCA) is a common technique used to evaluate the whole life cycle of the product and this includes assessing how green the product is and the real environmental impact of the targeted product. This article evaluates traditional core and insulation foams in terms of environmental impact, and compares them with the innovative polyethylene terephthalate (PET) foams.

Polymeric and Core Foams

Polymeric foams are insulation materials that play a major role in building and construction, where low cost polystyrenes (EPS/XPS) and high-insulating polyurethnes (PUR/PIR) have been extensively used. However, in recent years, the structural properties of certain rigid foams have attracted significant interest in the building sector as they are lightweight and have relatively good mechanical properties.

Unlike insulation foams, core foams have often different requirements and more importance is given to mechanical properties such as shear strength, compression, ageing, fatigue, and various impact and creep properties. Generally, foams with higher density are preferred because of their superior mechanical properties.

Polyethylene Terephthalate Foams

Figure 1. Polyethylene terephthalate plastic.

Considered as an engineering plastic, polyethylene Terephthalate (PET) (Figure 1) has superior thermal and mechanical properties. This plastic has a huge demand in the bottle, textile, and packaging industry and hence has become a commodity plastic in terms of availability and price. PET is also the most recycled plastic material in the world and is available worldwide with a yearly capacity of 5 million tons.

Properties of Polyethylene Terephthalate Foams

PET is thermoplastic by nature and hence can be processed repeatedly. The plastic is REACH compliant, ROHS compliant, recyclable, and contains no CFCs, fibers, heavy metals, carcinogens and mutagenes. Moreover, PET is an excellent insulation material and offers good protection against moisture and condensation. It does not rot or mold.

Life Cycle Assessment

As mentioned above, LCA is a method where the entire life cycle of the product is assessed. In order to complete the assessment, a wide range of data is needed - from production and transport of raw materials and finished goods to heating of office buildings and travel of individual employees. For this purpose, a number of commercial software and databases exist; in this study, SimaPro 7.2 software was utilized with EcoIndicator 95 v2.1.

The LCA of PET foam is based on actual information from Armacell Benelux from 2011. For other foams, information has been obtained from databases and publications.

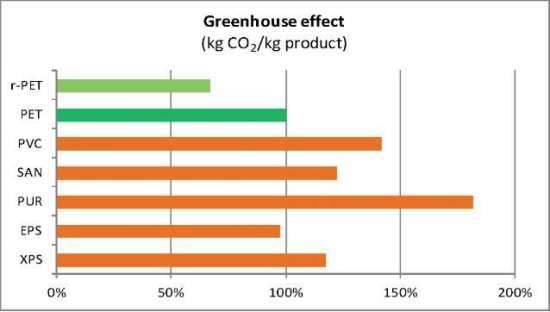

The carbon footprint is the amount of CO2 created per unit of the product in evaluation, and represents the typical referred result from LCA. In this study, the carbon footprint of different foams has been compared and the results are illustrated below in kilograms of CO2/kg of foam produced. Here, the 100% (PET) correspond to 3,23kg CO2 emission.

Figure 2. Greenhouse effect (kg CO2/kg product).

The light and green colors (Figure 2) signify the amount of CO2 generated per 1kg of PET foam made of virgin resin and the amount of CO2 generated for PET foam made of post-consumer material, respectively. The results demonstrate that PET foam exhibits a low carbon footprint in comparison.

Similar comparison has been done with regard to total solid waste produced and total energy consumed during the entire lifecycle of different plastic foams.

PET foams have excellent environmental characteristics as they consume less energy in production and generate less waste than other materials. When the foam is utilized for applications where insulation properties are important, the LCA values become extremely attractive because the product does not impact the environment after being installed.

Green Building Directives

Green building, also called as green construction or sustainable building, is a process or structure that is resource-efficient and environmentally responsible throughout the whole life cycle of a building, from building location to design, construction, maintenance, renovation, and final demolition.

To this end, a number of national and international green building directives have been introduced worldwide, and among these the American LEED (Leadership in Energy and Environmental Design) certification is recognized universally as the mark of quality for achievements in green building design, construction, operations and maintenance.

LEED offers third-party verification of green buildings and addresses the whole lifecycle of a building by centering on six important criteria such as site location, innovation and design, materials and resources, indoor quality, energy performance, and water use.

In order to receive LEED certification, a project must satisfy all LEED prerequisites and get at least 40 points on a 110-point LEED rating system scale:

- 40 = minimum for certification

- 50 = silver certificate

- 60 = gold certificate

- 80 = platinum certificate.

Figure 3. The number of points determines the level of LEED certification.

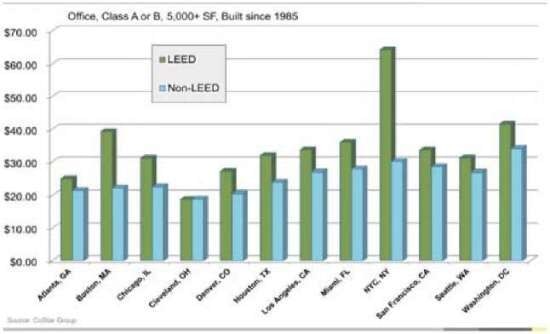

Figure 4. Office rental prices on LEED-certified and non-LEED certified buildings throughout USA.

Figure 3 shows the number of points required to earn LEED certification; Figure 4 shows the value of LEED certification. It has been shown that buildings which received LEED certification are believed to be more valuable than non-LEED certified buildings. With respect to eco-friendly insulation and core foams, such as PET foams, several LEED criteria can be positively influenced and they include improved insulation efficiency (maximum 19 points of 35); potential in innovation and design (maximum 4 points of 5); use of resource and recycled material (maximum 7 points of 5); and LCA data (maximum 7 points). This makes a total potential of 37 points out of 100.

Conclusion

The environmental impact of PET foam has been evaluated using the LCA method and compared with standard insulation and core foams. From the above data, it is clear that the PET foam exceeds existing materials in all relevant categories.

This information has been sourced, reviewed and adapted from materials provided by Armacell Benelux.

For more information on this source, please visit Armacell Benelux.