In use-wear analysis, traces remaining on the surfaces of stone tools are identified to reconstruct the method of operation of archaeological tools. Optical microscopy is traditionally used to determine the wear traces. At present, a large number of use-wear techniques are available in order to measure functional traces on stone tools.

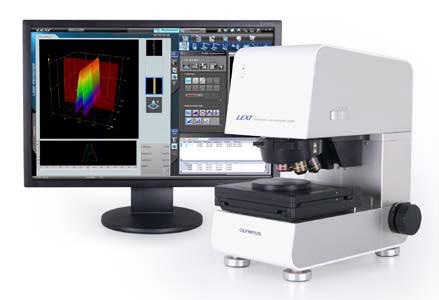

Most of these techniques measure topographic characteristics at small scales in order to gain insights into the difference in surface texture caused by different contact materials, such as wood, meat and antler. This article discusses the application of the Evident LEXT OLS4000 laser scanning confocal microscope (Figure 1) to determine the impact of different cleaning techniques on the surface roughness of experimental stone tools employed to cut wheat.

Figure 1. Evident LEXT OLS4000 Laser Scanning Confocal Microscope

Instrumentation

Laser scanning confocal microscopy (LSCM) is increasingly used in archaeological analyses for use-wear quantification of stone tools. It performs surface texture characterization by making quantitative surface roughness measurements through the construction of 3D models of surface features.

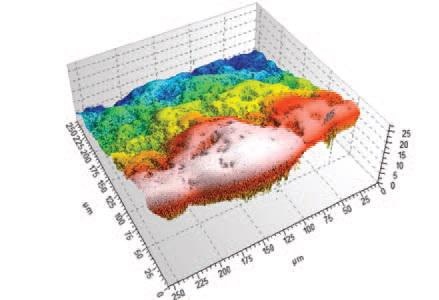

These measurements are helpful in differentiating polishes from different contact materials (Figure 2). The LEXT OLS4000 provides high-resolution images and surface measurements, making it suitable for this research.

Figure 2. Three-dimensional image taken with an LSCM of a stone tool used for harvesting wheat. The tool’s edge is oriented toward the bottom of the screen.

Experimental Procedure

This research involved three levels of cleaning of experimental stone tools: first with alcohol, followed by soap and water and finally chemical cleaning using hydrochloric acid (10%) and potassium hydroxide (10%).

Harvesting Experiment Setup

Harvesting experiments were carried out in August 2011 in Southern France for five days. Einkorn wheat (Figure 3) was planted in the harvested field to resemble ancient harvesting activities. The experimental sickle employed for harvesting was the replicate of an archaeological piece collected from the Natufian occupation at Kebara Cave (Israel) (Figure 4) and equipped six chert geometric microlith stone tools (Negev chert).

After using the sickle for roughly 12,000 strokes, two microlith inserts were selected from the sickle for the subsequent analysis to assess the variations in cleaning protocols.

Figure 3. Harvesting field located outside the town of St. Vallier de Thiey.

Figure 4. Experimental sickle used for harvesting experiment.

Sickle Insert Analysis Techniques

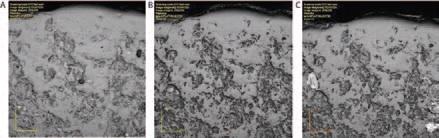

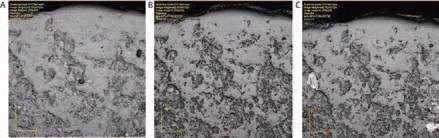

The first stage of analysis involved cleaning the stone tools with methyl alcohol and technical wipes. This reduced the residue transfer between the cloth and the artifact. After cleaning the pieces, the LEXT OLS4000 was used to scan them using the 20x objective and 50x objective, respectively (Figures 5a and 6a).

The second stage involved the cleaning of the stone tools with warm water, a mild detergent (nutratek) and a soft-bristled toothbrush. Once the cleaning was completed, the LEXT OLS4000 was used to scan the same location and at the same magnification (Figures 5b and 6b).

The final stage involved the chemical cleaning of the stone tools in order to remove organic deposits by soaking them in a 10% KOH bath for 10 minutes, followed by one-minute soaking in 10%HCl to eliminate any mineral deposits.

This is then followed by bathing in clean water in order to wash any chemical traces left behind on the stone tools. Next, the LEXT OLS4000 was used to scan the cleaned microliths (Figures 5c and 6c). Here, the cleaning techniques were increasingly invasive during each stage of the analysis.

Figure 5. Stone tool #1 a) cleaned with alcohol, b) cleaned with soap and water, c)cleaned with KOH (10%) and HCL (10%).

Figure 6. Stone tool #2 a) cleaned with alcohol, b) cleaned with soap and water, c)cleaned with KOH (10%) and HCL (10%).

Experimental Results

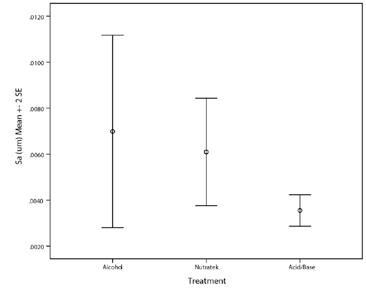

The results reveal that the adequacy of alcohol cleaning is not up to the mark for both use-wear quantification and visual interpretation of use-wear (Figures 5a and 6a). For tool #1 that was cleaned with alcohol, surface measurements of average roughness show a high variance (Figure 7).

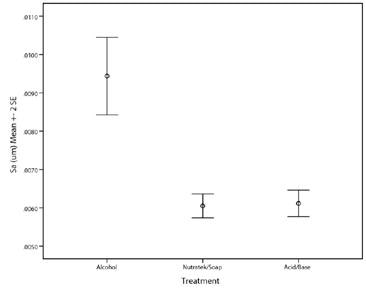

For Tool #2, both average roughness and variance are high (Figure 8) as a result of the presence of particulate matter with a rough texture and greases with a smooth texture in conjunction with the texture of the worn surface produces a highly variable surface. This interpretation is strongly supported by Figures 5a and 6a that clearly show the presence of grease and other particles.

Figure 7. The average roughness for stone tool #1 with alcohol, nutratek, and chemical cleaning.

Figure 8. The average roughness for stone tool #2 with alcohol, nutratek, and chemical cleaning.

The grease and most of the particulate residue were removed when cleaned with a detergent, thus producing lower-variance measurements for both tools. Chemical cleaning removed small particulate matter from the surface, as can be seen in Figures 5c and 6c, revealing a considerable reduction in the texture variation for both tools, especially for tool #1.

Conclusion

The results clearly demonstrate that the surface texture is affected by cleaning practices. Variations between the different cleaning stages can be visually observed, highlighting the importance of sample preparation for use-wear analysis. For surface texture measurements, acid/alkali cleaning is recommended before imaging for metrological purposes.

The drastic difference in the measurements for tool #1 after detergent cleaning and chemical cleaning recommends the use of chemicals for the complete removal of all materials adhered on lithic surface. The study results are useful in the standardization of sample preparation and demonstrate the advantage of using the LEXT OLS4000 in use-wear analyses.

This information has been sourced, reviewed and adapted from materials provided by Evident Corporation - Industrial Microscopy.

For more information on this source, please visit Evident Corporation - Industrial Microscopy