Components of different concentrations are often found in food aroma profiles, but compounds that are odour- active are usually present in small amounts. Hence it is important to ensure that all aspects of the analysis and sampling processes are optimized to allow detection and identification of a wide variety of analytes.

The aroma of strawberries is among the most complex fruit aromas and has attracted significant attention, especially in terms of identifying the olfactory components that distinguish different varieties of strawberries.

This article describes the application of a microchamber-based analytical setup that provides low detection limits required for identifying important volatiles without affecting the speed, flexibility, and ease-of-operation in food analysis.

Background to the Sampling and Analysis Methodology

Sampling and analysis of the strawberry samples are performed using the following techniques:

- Dynamic headspace sampling removes the organic vapours from the strawberry and transfers them onto a tube filled with sorbent

- Thermal desorption concentrates the organic vapours and transports them into the GC of carrier gas for improved sensitivity

- Analysis utilizes the time-of-flight mass spectrometry method, which is highly sensitive

- Compound-identification ramps up data processing by detecting and validating the characteristics of headspace components

Dynamic Headspace Sampling

The Micro-Chamber/Thermal Extractor from Markes is an advanced sampling accessory specifically designed to allow headspace sampling of organic vapours from an extensive range of materials. The accessory is easy to use and offers short sampling times of less than 60 minutes. Depending on the selected model, it can analyze four to six samples simultaneously.

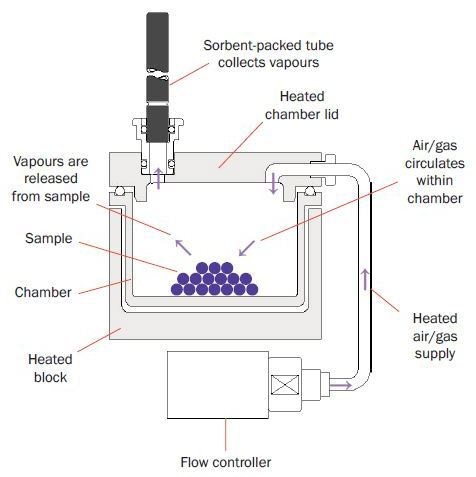

For the experiment, the strawberry sample is placed in one of the microchambers that are inert-coated and can be heated, as shown in Figure 1. Inert gas or air is then passed into the multi-hyphenated microchamber at a steady flow rate.

This process ensures that the headspace vapours are transferred onto a tube packed with sorbent for the thermal desorption stage. During this constant flow, large amounts of headspace vapours are collected from the volatility range. This improves the level of sensitivity and also ensures that the sample represents the whole aroma or odour profile under the specified temperature conditions.

Figure 1. Schematic showing operation of an individual microchamber for sampling organic vapours from samples such as fresh foodstuffs.

Thermal Desorption

Thermal desorption (TD) is a ‘front-end’ technique developed for GC and GC–MS instruments and can be used for studying volatile and semi-volatile organic compounds (VOCs and SVOCs) in a range of sample matrices such as solids, liquids, and gases.

This method integrates processes like pre-concentration, desorption and extraction, and GC injection into a fully automated and sensitive operation, which eliminates the necessity for solvent extraction with its related limitations of interferences, dilution and manual preparation of samples. When TD is used along with dynamic headspace, it provides a high level of sensitivity for studying VOC profiles from fresh foodstuffs.

In this experiment, the sorbent tubes that were utilized to obtain strawberry headspace vapours were examined using TD in tandem with GC–TOF MS method. The sampled tubes were then heated in an inert carrier gas during the two-stage thermal desorption method. The components thus released from this process were delivered to a smaller ‘focusing’ trap that was electrically cooled and integral to the TD solution.

Once the primary desorption stage was over, the focusing trap was desorbed rapidly by heating it in a reverse flow of carrier gas to inject or transfer the organic compounds within the capillary GC analytical column. The two- stage desorption process not only helps in optimizing concentration enhancement, but also creates narrow chromatographic peaks, which in turn improves the level of sensitivity.

Markes’ TD systems also provide other benefits, which make them ideal for complex odour profiling applications. These benefits include:

- Electrical cooling of the secondary focusing trap removes the necessity for liquid cryogen, saving significant amount of time and money. It also allows for accurate water management and temperature control.

- The backflush or reverse operation of the focusing trap and sorbent tube enables sequential use of various sorbents. This helps in extending the volatility range of compounds.

- Gentle heating of the tube along with the inert flowpath makes the system suitable for reactive compounds such as sulfur compounds and amines.

- Samples can be divided during desorption process and the remainder samples can be again collected and examined under same or different conditions.

Markes’ fully automated thermal desorber TD-100 was used in this study. This system can carry 100 sorbent tubes and enables complete automation of sample desorption and re-collection.

Time-of-Flight Mass Spectrometry

In this experiment, ALMSCO’s BenchTOF instrument was used that is specifically designed for gas chromatography. The BenchTOF systems provide complete spectral data at high sensitivity which makes them suitable for detecting analytes even at trace levels. Reference-quality ‘classical’ EI spectra obtained from these instruments help in comparing against NIST library.

Compound Identification Software

TargetView is a data-processing software package that further improves the sampling and analysis setup. The software enables automated and precise identification of trace compounds in challenging GC–MS profiles, and utilizes advanced algorithms to process data related to total ion chromatography (TIC). With the help of TargetView, unknown as well as target compounds can be easily identified at trace levels.

Experimental Framework

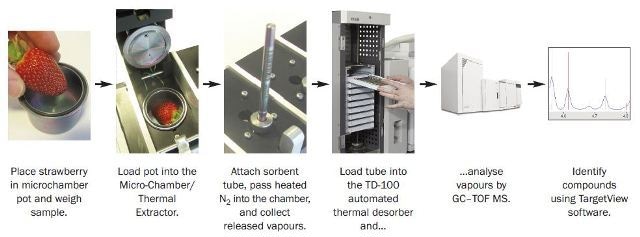

Figure 2 shows the extraction and analysis process, where whole strawberries have been accommodated by the microchamber system, which is otherwise not possible with a conventional 20mL headspace vial.

Figure 2. Flow chart showing the process used to sample and identify the volatile compounds released from strawberries.

For sampling, Markes’ Micro-Chamber/Thermal Extractor, inert-coated chambers, and sorbent- packed tubes were used; for thermal desorption process, TD-100 thermal desorber and Material Emissions trap were used; and for TOF MS method BenchTOF system was employed.

Results and Discussion

Emission Profile of a Whole Strawberry

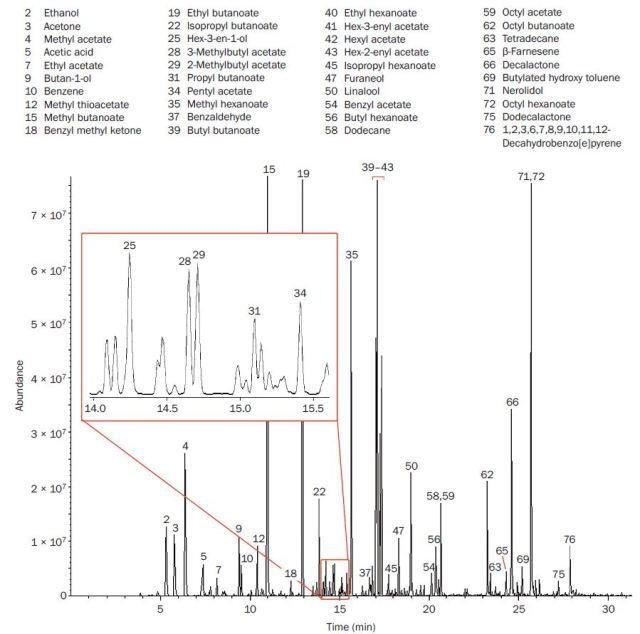

Figure 3 illustrates an example of emission profile for a whole strawberry. In order to create a list of the major components in this sample, the TargetView software includes options for the ‘all-component’ search that were adjusted to identify the 100 most abundant peaks against the NIST 11 commercial database. Ultimately, a list of 76 known compounds was obtained, with most of them being esters as major olfactory components.

Figure 3. Analysis of the headspace profile of a whole strawberry, sampled onto a Tenax TA–SulfiCarb sorbent tube using the Micro-Chamber/Thermal Extractor, and analyzed by GC–TOF MS. The 40 most abundant compounds are labeled.

Comparison of Chopped and Whole Strawberries

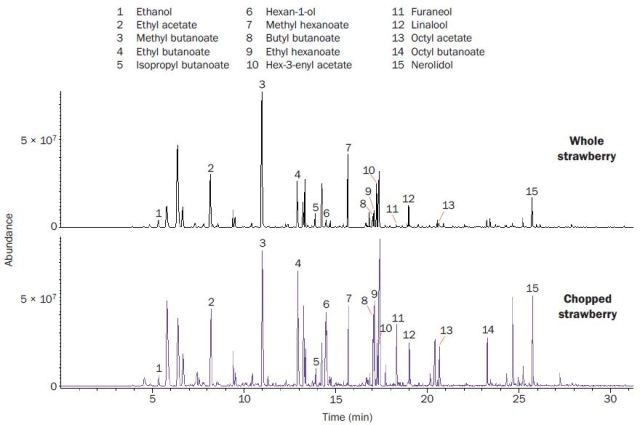

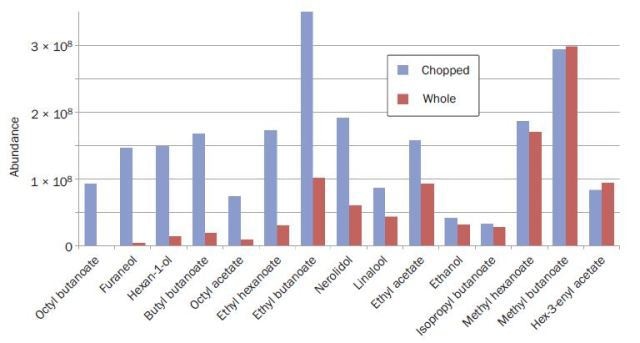

When the strawberry is cut prior to placing in the thermal extractor or micro-chamber, high levels of volatile compounds are released, as shown in Figure 4. TargetView was then used to process these two chromatograms against a customized library which helped in obtaining the deconvolved peak regions for both samples. The values thus obtained are compared in Figure 5.

Figure 4. Comparison of the headspace profiles of whole and chopped strawberries sampled onto a Tenax TA–Carbograph 5TD sorbent tube using the Micro-Chamber/Thermal Extractor, and analyzed by GC–TOF MS.

Figure 5. Comparison of peak sums for selected volatiles in the headspace profiles of whole and chopped strawberries shown in Figure 4. Compounds are displayed in order of decreasing [chopped]/[whole] ratio.

The data shows the effectiveness of using the Micro-Chamber/Thermal Extractor for performing instant comparisons of analogous foodstuffs such as, in this case, samples prepared using different methods. In addition, detection of sulfur compounds was made easier through the TargetView package. The search showed the presence of seven sulfur species from the library. However, sulfur compounds are difficult to study through traditional GC methods.

Conclusion

Sensitive techniques such as thermal desorption, dynamic headspace extraction, and TOF MS together with the TargetView software package can be used to profile strawberry aroma compounds.

This approach can aid in determining odour-active compounds and for analyzing the variations in volatile profiles between strawberry varieties or cultivars. Also, the combination of TD-100 thermal desorber and Micro-Chamber/Thermal Extractor enables fast and simple sampling of VOCs and SVOCs.

About Markes International Limited

Markes International is a specialist manufacturer of analytical thermal desorption instrumentation and associated sampling equipment. The company's comprehensive portfolio of products is designed to automate and enhance the measurement of trace level volatile and semi-volatile organic chemicals (VOCs and SVOCs) in real-world samples.

For over a decade, Markes International has pioneered analytical thermal desorption (TD) instrumentation and associated sampling equipment. Markes has also the widest range of thermal desorption consumable products on the market; the company is widely regarded as being the World leader in thermal desorption technology.

This information has been sourced, reviewed and adapted from materials provided by Markes International Limited.

For more information on this source, please visit Markes International Limited.