Free radicals are molecular or atomic species with unpaired electrons, and therefore are highly reactive. These chemical species control a number of basic chemical processes in nature, particularly oxidation and combustion.

Direct measurement of the concentration and composition of free radicals has always posed a challenge to chemists owing to the complexity and cost of the equipment.

Figure 1. Micro-ESR™ Online Oil Analysis System, 10”x 8” x 5”.

The Micro Electron Spin Resonance spectrometer (Micro-ESR™) by Bruker Biospin is a low cost, compact and rugged device that makes it possible to measure free radicals (Figure 1).

The Micro-ESR™ allows for novel applications such as on-line measurement of lubricant breakdown in gas turbines, hydraulic systems, machinery, engines, thermal coking of gearbox oils, and raw fuel dilution in marine engine lubricants, amongst others.

This article briefly describes the test data and results, which were obtained using this latest technology to test a range of crude oils and lubricants.

Electron Spin Resonance Spectroscopy

An electron spin resonance (ESR) spectrometer is capable of detecting the composition and concentration of free radicals in a sample. The sample was first loaded into a high frequency resonant cavity in a fluctuating homogeneous magnetic field.

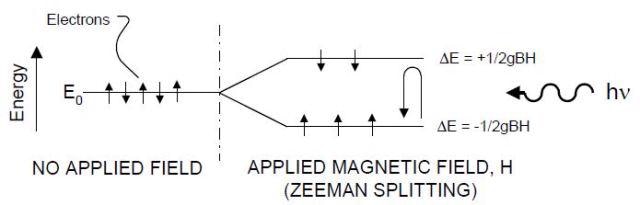

Unpaired electrons when irradiated with microwave radiation at a set frequency will undergo resonant changes between the spin ‘down’ and spin ‘up’ state under a magnetic field (Figure 2).

Figure 2. Electron transitions stimulated by incident microwave energy.

‘B’ is the Bohr Magneton and ‘h’ is Planck’s constant, H is the applied magnetic field, ν is the resonant frequency, g is a characteristic of the radical (the “g-factor” is an experimentally determined number and is usually close to 2.0000).

The magnetic field at resonance is a virtue of the g-factor, and the double integral of the resonant peak was measured by the concentration of the radical in the sample.

Given that the ESR effect was first determined in 1945, ESR spectrometers were designed using water-cooled electromagnets to produce a variable magnetic field. In contrast, Bruker Biospin’s Micro-ESR™ spectrometers use strong and small rare-earth magnet assemblies featuring a low power electromagnet coil.

The specimen is restricted in a high-Q resonant cavity that has a large ‘fill factor’ corresponding to a traditional ESR. This way, excellent sensitivity can be achieved with a compact device. Additional innovations in the design of the receiver and microwave bridge further reduce the size and cost of the Micro-ESR when compared to traditional ESR spectrometers.

Application to Lubricant Degradation

Free radicals are created by exposing oil to extreme pressures and temperatures in the presence of oxygen. Usually, antioxidants are introduced to the base oil, which in turn reacts with the peroxy radical and make it harmless. Nonetheless, as the antioxidants in the oil are consumed, the concentration of peroxy radicals increases, resulting in breakdown.

The free-radical species generated from oxidation reactions give rise to ESR signals, which are determined by the Micro-ESR spectrometer. These oxidation signals match well with other ASTM-standard measurements, such as FTIR spectroscopy.

Hydraulic Oils and ASTM Correlation

Samples of hydraulic oil were obtained from nuclear submarines for testing and comparison to ASTM-standard analysis techniques such as FTIR for oxidation measurement. These oils are grade 2075 hydraulic oils.

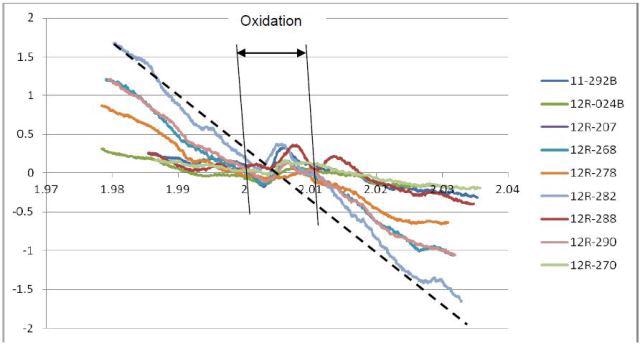

Figure 3. Oxidation and corrosion in hydraulic oils.

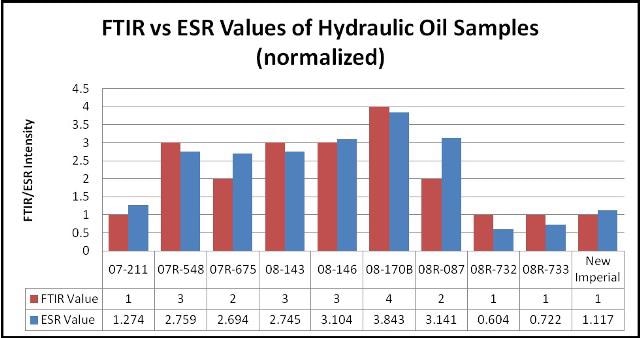

Figure 4. Comparison of ESR and FTIR ASTM D7414 analysis techniques.

Figure 3 shows the standard free radicals signals seen in hydraulic oils. This data reveals a narrow central line owing to an organic radical generated by oxidation processes. A wide background line is also seen which looks like a slope in these graphs. This wide line can be attributed to iron oxides from ferrous corrosion in the hydraulic device.

The peak height of the oxidation signal was evaluated against ASTM-standard FTIR measurements of oxidation conducted by an outside lab. As indicated in Figure 4, a number of engine oils were analyzed using Micro-ESR.

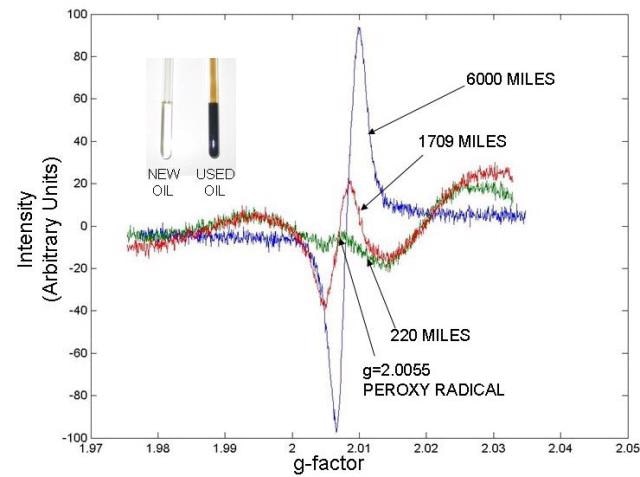

In the case of gasoline engine oils, a simple ESR peak caused by thermal oxidation was observed. The graph in Figure 5 displays the original results for a field test performed on a Honda sedan:

Figure 5. Field test of oxidation measurement by electron spin resonance spectroscopy.

In the field trial of gasoline engine, a Honda accord was driven for a distance of 6000 miles without any top up or oil change. Small samples were taken from the engine sump to measure the rise in the oxidation free radical signal.

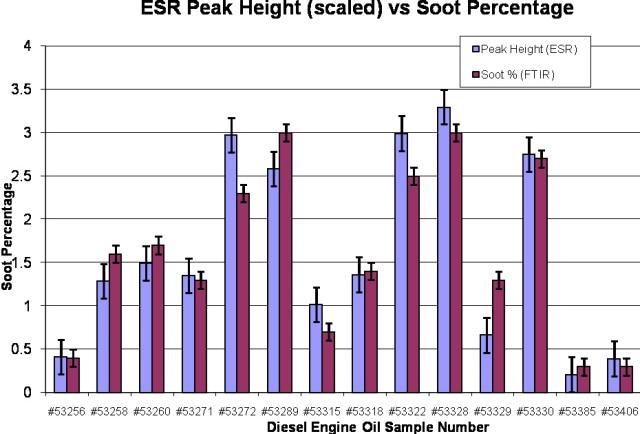

Then, further testing was carried out on diesel engines. Often, high concentration of soot is found in diesel engine oils that can produce a second, overlapping signal in an ESR spectrometer. Measurements of % soot content relate well between FTIR and ESR (Figure 6).

Figure 6. Correlation between ESR and FTIR measurements of soot in diesel engine oil.

Gearbox Oil and Thermal Coking

In this experimental study, the Micro-ESR was used to determine oxidation as well as thermal coking of gearbox oils. Although thermal coking-related failures are rare, they are often costly to repair.

Figure 7. Thermal coking of Grade 2190 Gearbox Oils measured by X-band Micro- ESR

In Figure 7, gearbox oils were heated to 250°C for a number of hours. These oils degraded and precipitated black sludge along with a free radical signal. Micro-ESR spectroscopy was subsequently used to determine the degradation of gearbox oils in real time during the heating process.

A direct correlation was observed between ESR signal intensity, temperature and time as well as between mass loss and ESR signal intensity. The headspace of the reaction chamber was then analyzed to ascertain the chemical composition of the vapor being produced.

Gas chromatography was used for this purpose. The outcome of the GC study demonstrated that the oils release highly volatile byproducts, which indicated that thermal coking and cracking were occurring in this case.

Finally, tests were run to compare flash point with ESR signal intensity as determined by ASTM D91. As expected, flash point did not correlate closely with oxidation.

This data shows how the on-line oil condition monitoring solution was able to detect the sudden onset of hazardous breakdown conditions in critical machinery. However, an offline measurement and sampling protocol would not have detected a major event like this and thus would have failed to alert the equipment operator to take remedial action.

Marine Lubricants: Residual Fuel Dilution

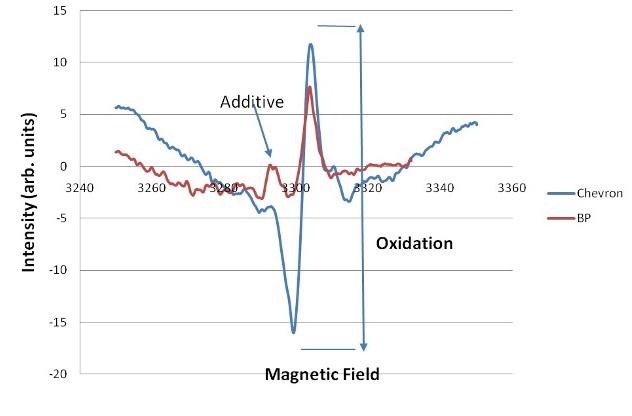

Vanadium is found in many crude oils in the form of vanadyl porphyrin. When vanadyl porphyrin is burned, it changes to vanadium oxide, which is not possible to observe by ESR. However, vanadyl porphyrins together with asphaltenes have signals that can be readily identified and determined by Micro-ESR technology.

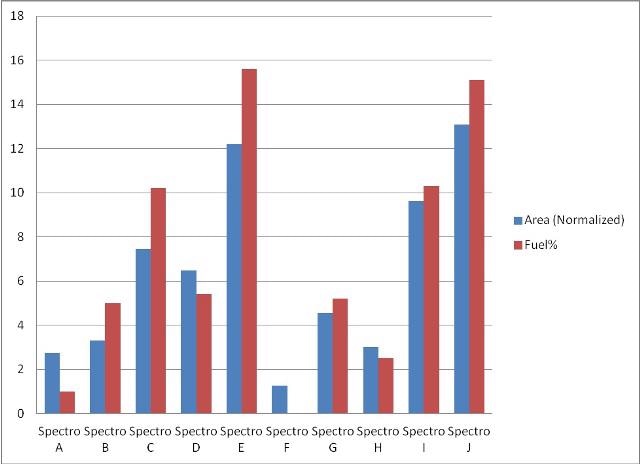

A range of marine lubricants with different percentages of raw fuel dilution was studied. Figure 8 shows the results, where the ESR spectra of asphaltene and vanadyl porphyrin can be clearly seen in the marine lubricant.

The ESR results were measured and then evaluated against raw fuel dilution measurements performed using precipitation.

Figure 8. Vanadyl porphyrin signal intensity compared to precipitation measurement.

Conclusion

Micro-ESR can determine intrinsic chemical properties of oils, unlike other on-line oil analytical methods that measure only electrical or physical properties of oils. The presence of various factors can easily confuse less advanced measurement methods. On the other hand, Micro-ESR provides an absolute reading of the condition of oils.

If an ESR spectrum is present, it indicates that contamination is present in the oil. Also, the specificity of ESR means that no compounds other than transition metal ions and free radicals will create a signal. Therefore, this method does not have cross- factors that are commonly associated with other sensors.

The Brker Biospin Micro-ESR™ Oil Condition Sensor can be used in vehicle fleets such as rail, shipping, military vehicles, heavy equipment, wind turbines, power generation, and heavy equipment.

This information has been sourced, reviewed and adapted from materials provided by Bruker BioSpin - NMR, EPR and Imaging.

For more information on this source, please visit Bruker BioSpin - NMR, EPR and Imaging.