Features, physical components, and technical specifications of an Isothermal Titration Calorimeter (ITC) instrument should be considered in the purchase of a new system. However, systems with the best components and technical specifications are not necessarily user-friendly. Users must select the appropriate instrument based on their application requirements. This article discusses some of the key factors that need to be considered in the purchase of an ITC.

Sample Consumption

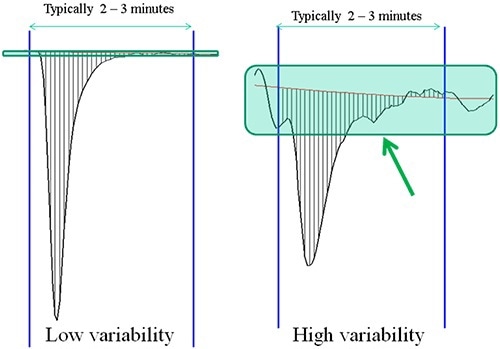

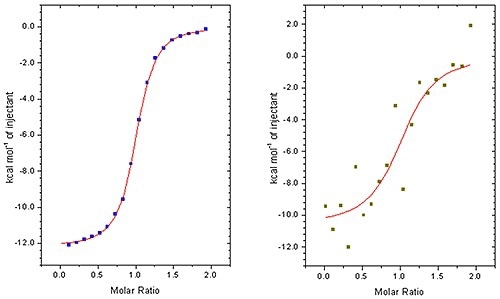

A good ITC binding curve consists of an array of injection heats, and the ability to accurately measure the area of injection peaks directly influences the values of parameters such as the Kd (Figure 1), especially at low sample concentrations (Figure 2).

Figure 1. Comparison of ITC injection peaks.

Figure 2. A good and bad ITC isotherm. When peak areas can be measured accurately it is much more likely that the experimental data points fit well to the fitted binding isotherm.

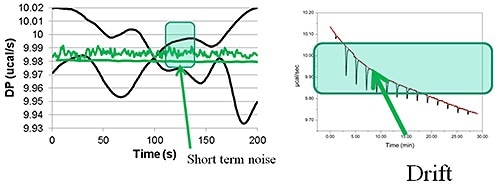

Although the baseline variability from most of the vendors seems to be ‘OK,’ the raw data is often manipulated before the analysis process (Figure 3). This is a time-intensive process and increases uncertainty in the KD data and other parameters.

Figure 3. Examples of short term noise and drift. The green lines on the left hand figure show two examples of short term noise. The higher data set having the higher noise. However, either would be OK for measuring peak areas of typical ITC data.

Making measurements at low concentrations is good to test the accuracy of peak area measurement. The robustness of the process can be evaluated through comparison of the affinity and other thermodynamic parameters produced from repeat experiments.

Repeatability

Getting reproducible results even at higher concentrations is affected by a number of factors, including cleaning of the syringe. It is recommended to use a calorimeter that enables easy cleaning of the syringe and subsequent drying. Injection repeatability is another factor. A preferred calorimeter must feature a precision pipette capable of delivering very low volumes with high repeatability.

User-Friendliness of Instrument and Software

It is necessary to assess whether both the hardware and software are easy to use. Syringe loading and drying must be rapid and simple. The visibility of the cell port is another key factor for sample loading into the calorimetric cell without introducing bubbles. Users have to do the data analysis on the instrument by themselves in order to assess the software.

Response Time

An ITC instrument’s response time directly affects both sample consumption and analysis time. Comparing the time taken to run and set up experiments by each instrument helps understand which instrument has the faster response time. ITC Instruments that have quick response time can perform more experiments in a day with low sample consumption in most of the cases. Upgrading instruments to an automated platform will be helpful to handle huge calorimetric data.

Ability to Measure a Broad Range of Affinities

Low sample concentrations are required to measure the affinity of tight interactions on an ITC, which should be able to accurately quantify small heats. Factors such as response time and baseline variability should be considered to the ability of the instrument to perform this measurement. The inherent heat of the binding process is another factor that needs to be considered.

To assess the performance of ITC instrument in the measurement of tight interactions, samples at low concentrations have to be used and the variability in the affinities from repeat experiments needs to be checked. Samples at higher concentrations need to be used to measure weak interactions. For such measurements, easily loadable ITC instruments are recommended for repeatable measurements with reduced loading errors.

Ability to Handle Multiple Applications

Users must check whether the ITC instrument is capable of handling their specific applications. The thermal properties of gold make it ideal for heat measurement. The interactions between proteins and disulfides can be measured with a calorimeter having a cell that is inert in terms of reactions with thiol groups.

Reliability of the Instrument

With limited samples, it is necessary to use an ITC instrument that generates reliable results. Users can find the appropriate instrument by exploring the literature and observing what type of ITC instrument is being used by the high impact groups.

Reputation of the Manufacturer or Vendor

Assessing the reputation of the manufacturer or vendor of ITC instruments is also important. Users have to search for manufacturers who have excellent track record in the development and optimization of ITC instruments. These manufacturers not only make systems with little instrument-to-instrument variability, but also advance technology and applications. They have the experience and resources to manufacture innovative instruments and provide continuous support to them.

Post- Sale Service and Support

It is recommended to procure instruments from a company capable of providing after-sales support in person and through telephone and email, expert level support, field base service, and continuous training opportunities. Hence, users must check out what support is offered by the company before purchasing an ITC instrument.

Price Factor

Design, performance and quality differ from instrument to instrument. Although the specifications of different ITC instruments may look like the same on paper, they vary significantly in actual performance, longevity and quality. The cheapest instrument often does not have the best long-term value and will incur more cost in the long run. Slow instruments with poor repeatability wind up costing more by consuming more samples and taking more time to produce results.

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical.

For more information on this source, please visit Malvern Panalytical.