A differential scanning calorimeter (DSC) instrument’s physical components and features, as well as the technical specifications, are vital to consider when acquiring a new instrument. This said, it can be quite confusing to follow written specifications, which can be misleading and may not provide useful data on the actual performance of the instrument.

In terms of performing actual measurements on samples, written specifications do not necessarily translate to advantages or disadvantages. Even the most impressive technical specifications and advanced components are irrelevant if the instrument is not assembled or optimized in a manner which translates into improvements in ease of use and data quality when working with samples.

The following article is a list of questions that a customer should ask about differential scanning calorimeters prior to purchase.

Key Differences Between Instruments

Every Manufacturer uses different jargons and expresses specifications about instruments in unique styles. Nevertheless, understanding application needs and the specifications and features required to suit the application is critical for choosing a DSC instrument.

Certain questions that customers should ask themselves as they evaluate differential scanning calorimeters are:

Is Sample Consumption Important to You?

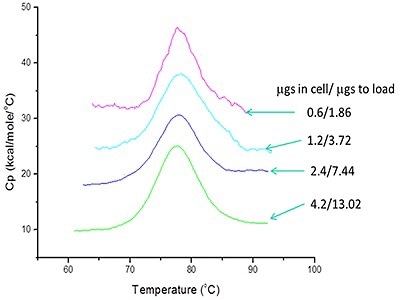

Noise comparison is a very common way to assess an instrument’s sensitivity. Although it is rational to an extent, these values can be tricky to compare between vendors, as each might classify noise in their own way. A better method would be to run samples at low concentrations and execute repeat experiments. Also, a test system, which is not concentration dependent, can operate the samples at a series of concentrations and compare the resultant values (Figure 1).

Another factor that needs to be considered is the volume of material that would be required by the user to fill the cell appropriately. DSC instruments with a range of volumes are available in the market. Therefore, while selecting a DSC, both the amount of sample (weight) as well as the sample concentration has to be considered (Figure 1).

Figure 1. DSC data for protein denaturation at a range of concentrations. The values on the right show the total protein required for the measurement and the amount required to fill the cell.

Do you Want to Measure the Stability of Your Proteins or Other Macromolecules in a Broad Range of Buffers and Cosolutes?

The compatibility of the instrument for specific applications and buffer types has to be looked into.

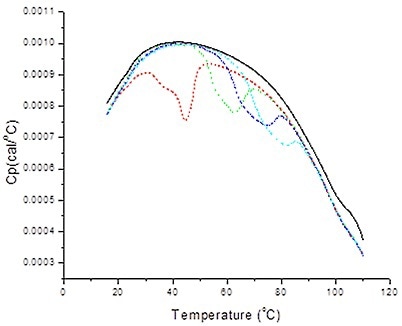

For example, platinum has thermal properties, which make it ideal for use in a DSC cell, but it is frequently used as a catalyst, making it incompatible for a range of applications. It has been observed that there are issues with platinum with a number of generally used buffers, therefore, it should be avoided when analyzing a range of biological systems (Figure 2).

Figure 2. Repeat runs of a biological buffer. Data generated on a prototype DSC which had a platinum cell. The black trace is the output data for a water control experiment. The other traces are the data that was generated in the instrument when loaded with 50mM PIPES buffer, at pH 7. Ideally the water and buffer experiments would look the same. The PIPES data has unexplained artifacts that would have a negative impact on any measurements made using this buffer.

Do you Want to Maximize the Number of Experiments You Can Run in a Day?

Several DSC instruments can operate samples at 240°C/hr. This high speed scan rate allows for maximizing the amount of measurements that can be performed in a day. It is recommended that you check the scanning rate options on all the DSC instruments.

Is the Generation of High Quality Thermodynamic Data Important to You?

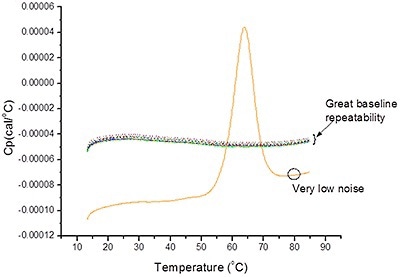

Baseline repeatability is a significant factor to think about in case the calorimeter is to be used for detailed thermodynamic analysis. It is important to assess whether the profiles of the blank buffer scans concur through a number of experiments performed under the same settings. Like many instruments, DSC requires start-up runs so as to ascertain repeatable performance.

After these preliminary runs, profiles of the buffer scans will be similar, with only minor shifts in the y-axis position and shape. There are specifications for baseline repeatability; however, it would be practical to check this by making a few of your own measurements.

Figure 3. A DSC trace of a thermal denaturation of a protein and a series of buffer control runs showing good repeatability.

How User Friendly is the Instrument and Software?

User friendliness is a key factor. The best method to assess this is to operate the instrument and perform the data analysis. Personal experience is paramount. The software needs to be used and an experiment should be performed from start to finish. Only this will give a complete picture of the instrument’s user-friendliness and time consumption.

Do You Need to Accommodate a Broad Range of Applications?

Numerous macromolecules and macromolecular assemblies can be examined using the DSC. If several people will be handling the instrument for a broad range of macromolecular assembly studies, then the instrument that is bought must match those requirements. For example, some assemblies like lipid micelles possess very narrow transitions that are completed over 2-3°C, while protein denaturation profiles normally occur over the 20°C range. Certain micro-calorimeters have user-adjustable response times, and this helps to optimize the performance of the instrument for various applications. Thus, if a wide range of applications is a requirement, then it is recommended to choose this type of flexibility in the DSC.

How Good is the Manufacturer or Vendor?

It is vital to evaluate the reputation of the manufacturer you would like to purchase from. DSC instruments have to be manufactured with high standards, and precision-engineered by leading technology companies so as to enable publication quality or decision making results. The manufacturer should have a history of developing and optimizing DSC instruments. Such companies have been through the learning curve and will possess the expertise, experience and support resources to build quality instruments as well as provide quality support.

What About Post-Sale Service and Support?

It is best to purchase a system from a company which provides acceptable service and post-sales support. A company with telephone, in–person and email support, ongoing training opportunities, field base service and expert level support is ideal for beginners. Before an instrument is purchased, enquire about the kind of support offered and try some of these services prior to making your decision. This will give an idea as to the quality of support.

Shouldn’t I Just Buy the Instrument with the Lowest Price Because They Are All Pretty Much the Same on Paper?

DSC instruments can vary massively in their quality, design, and performance, and although many of the instruments may have similar looking specifications on paper, they will be different in quality, real-life performance, and longevity. Buying a cheap product may cost more in the long run. Slow instruments have poor repeatability and cost more in terms of the additional sample and the time taken to produce data.

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical.

For more information on this source, please visit Malvern Panalytical.