Government regulations relating to the release of aromatic hydrocarbons such as benzene, toluene and xylene into the environment and their human exposure risks are well documented.

Figure 1. The MAX300-LG and the MAX300-IG

These hydrocarbons are collectively called BTX. Benzene has the lowest permissible Time Weighted Average (TWA); as low as 1 part per million (ppm) in certain industries. The Process Insights MAX300 series of quadrupole mass spectrometers are the perfect solution for the low ppm level analysis of BTX in air.

Key Capabilities of the MAX300 Series Quadrupole Mass Spectrometers

The benzene detection limit of the MAX300 is 10 parts per billion (ppb), which is 100 times better than the EPA’s time weighted average requirement of 1 part per million. Interferences caused by toluene and xylene are accurately subtracted in the analysis using the MAX300. As a result, false benzene readings can be eliminated. A single stream can be analyzed within 10 seconds due to its fast response. This means that using the MAX300, 80 streams can be analyzed within 15 minutes. The MAX300-LG and the MAX300-IG are depicted in Figure 1.

The comparison of EPA requirements and the detection limits of the MAX300 is listed in the following table:

| Component |

EPA Requirements (TWA) |

Process Insights MAX300 Detection Limit |

| Benzene |

1 ppm / 10 ppm* |

0.010 ppm |

| Toluene |

200 ppm |

0.011 ppm |

| o-Xylene |

100 ppm |

0.021 ppm |

*TWA of Benzene depends on Industry

Typical Analysis Information

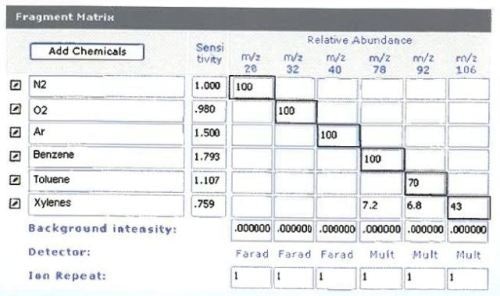

Figure 2 presents the typical analysis method for BTX measurements. Air components, such as nitrogen, oxygen, and argon, are also typically included in the analysis. The component analysis will be performed at masses (m/z) 28, 32, 40, 78, 92, and 106 amu, respectively. The standard air components are analyzed using the faraday detector, whereas BTX components are analyzed using the multiplier detector due to their presence at ppm level.

Figure 2. Analysis fragmentation matrix

Application Background

The Process Insights MAX300 series quadrupole mass spectrometers satisfy the environmental monitoring requirements for a variety of volatile organics present in air. In particular, the MAX300 is well suited for the low ppm level analysis of BTX in air. The on-line analysis of the MAX300 is very accurate and fast, taking only 400ms per component. Furthermore, it is capable of detection limits on the order of 10ppb when a multiplier detector is used in combination with the standard faraday detector. The superior performance of the MAX300 series has been proven and offers superior performance, especially in benzene analysis; exceeding the required detection limits.

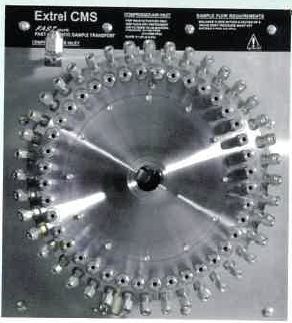

Besides offering a diverse range of standard rotary valve inlet configurations for use in process chemical applications, Process Insights supplies 80-port FASTValve (Figure 3) that is specially engineered for environmental applications, which normally involves the analysis of multiple streams. The Process Insights MAX300 series of quadrupole mass spectrometers is preferred for ambient air monitoring applications, thanks to its component selectivity, speed of response, and unprecedented accuracy and precision. Process Insights has installed over 70 ambient air monitoring systems across the world, of which several analyzers have been delivering superior performance for more than 15 years.

Figure 3. Process Insights FASTValve

Key Application Facts:

- The typical analysis cycle is less than 10 seconds/stream and the MAX300 can monitor 80 sample points within 15 minutes

- The 80-port high flow, rotary valve, the Process Insights FASTValve, is specially built for ambient air monitoring

- The MAX300 can reach a continuous dynamic range of 100% down to 10ppb with the Dual Faraday and Electron Multiplier Detector

- Process Insights’ Questor 5 web-based user interface can meet 21 CFR Part 11 requirements with its capabilities

- Various industry standard communications, such as Ethernet, OPC, MODBUS RTU or TCP/IP, Bi-directional MODBUS, and analog communication protocols, are supported by the Process Insights MAX300

This information has been sourced, reviewed and adapted from materials provided by Process Insights - Mass Spectrometry.

For more information on this source, please visit Process Insights – Mass Spectrometers.