Polymer production and quality control (QC) requires a range of analytical testing. One common QC test is the analysis of residual monomers in the final polymer material. This method is ideal for headspace sampling because headspace eliminates the sample preparation, and the sample can be directly analyzed without dissolving the polymer.

However, when using headspace for solid sample analysis, the sample matrix needs to be compensated as calibration standards cannot be created with the same matrix interactions.

Multiple headspace extraction (MHE) is a technique that enables complete extraction of a sample and calculate the amount of analyte by comparing against an external standard. This article demonstrates how the MHE-GC/MS technique is effectively used for testing polymers for residual monomers. The polymers analyzed in this study are used for producing corrective eyeglass lenses.

Multiple Headspace Extraction

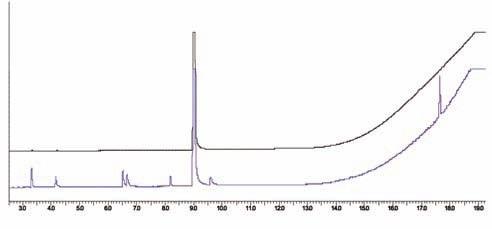

MHE technique is used to quantify samples in a difficult matrix or solid without matrix corresponding to the calibration standards. The standard is analyzed, without matrix, in a total evaporation headspace with MHE, determining a response factor as shown in Figure 1. In this method, users can choose MHE as an option to start a certain extraction process in the instrument.

Figure 1. Chromatogram of a MMA calibration standard by total vaporization (top); and chromatogram of the MMA in a PMMA sample (bottom).

The HS method in MHE tracks the normal extraction steps in the first round of extraction. After equilibration and pressurization of the vial, an injection is made and the vial is vented. Following the first round of extraction, the MHE method differs from a standard HS method – rather than ejecting the vial after venting, the vial remains into the headspace oven, it is re-equilibrated, and the injection process repeated. The instrument can run this process unattended for the number of times, up to nine, that the operator selects in the method.

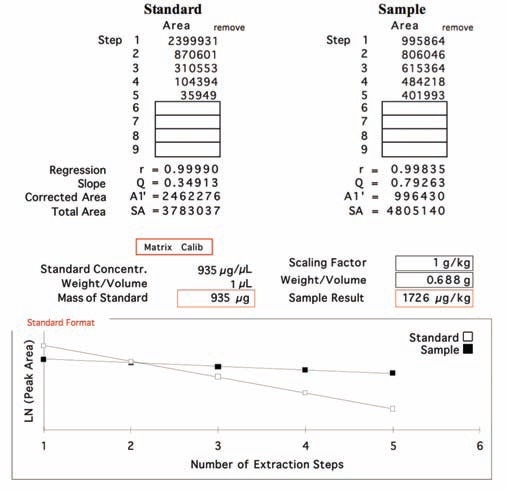

This technique makes it possible to completely extract the sample, and the data thus obtained is utilized to establish the overall amount of analyte present in the sample and the rate of extraction specific to the sample matrix. This information is added to a report template (Figure 2) and then utilized to measure the amount of analyte present in similar matrix samples.

Figure 2. Example of the Excel®-based macro used to calculate concentration of MMA in MHE.

Experimental Procedure

It is very simple to prepare a headspace sample. A headspace vial is filled with a sample of known weight and the vial is then crimped and placed within the PerkinElmer® TurboMatrix™ HS-40 Headspace Sampler (HS) . The parameters used for producing the headspace method are shown in Table 1, while Tables 2 and 3 present the conditions employed for the PerkinElmer Clarus® 600 GC/MS system.

The required separation was obtained with a PerkinElmer Elite™-5MS column, and both quantitative and qualitative data were obtained with the Clarus 600 MS used in full-scan mode.

Table 1. Headspace conditions used in analysis of monomers in polymers.

| Headspace Unit: |

PerkinElmer TurboMatrix HS-40 |

| Headspace Mode: |

MHE |

| Oven Temperature: |

180 °C |

| Needle Temperature: |

185 °C |

| Transfer Line Temperature: |

190 °C |

| Thermostat Time: |

30 min |

| Vial Pressurization Time: |

2 min |

| Withdraw Time: |

0.2 min |

| Injection Time: |

0.03 min |

| Column Pressure: |

120 kPa |

| Injection Pressure: |

160 kPa |

| Vial Pressure: |

160 kPa |

| Vial Vent: |

On |

Transfer Line:

|

Fused Silica (0.32 mm)

|

Table 2. GC Conditions used in analysis of monomers in polymers.

| Gas Chromatograph: |

PerkinElmer Clarus 600 GC |

| Analytical Column: |

PerkinElmer Elite-5MS (30 m x 0.25 mm x 0.25 µm) |

| Injection Port Type: |

Programmable Split/Splitless |

| Injector Temperature: |

200 °C |

| Injection Type: |

HS-Control |

| Carrier Gas Type: |

Helium |

| Carrier Gas Program: |

80 kPa Constant |

Oven Program:

|

| Temp. |

Hold Time |

Rate |

| 40 °C |

4 min |

5 °C/min |

| 160 °C |

5 min |

20 °C/min |

260 °C

|

2 min

|

End

|

|

Table 3. MS Conditions used in analysis of monomers in polymers.

| Mass Spectrometer: |

PerkinElmer Clarus 600 T MS |

| GC Inlet Line Temperature: |

180 °C |

| Ion Source Temperature: |

200 °C |

| Function Type: |

Full Scan |

| Full-Scan Range: |

m/z 45-350 |

| Full-Scan Time: |

0.35 sec |

| InterScan Delay: |

0.05 sec |

Solvent Delay:

|

0 min

|

Results and Discussion

In this experiment, 1µL of MMA was taken and vaporized in the vial, and the quantity of 935µg was measured with the known density. Up to five MHE steps were used to extract the sample completely. A polymethyl methacrylate (PMMA) sample of 0.688g was placed within a headspace vial and analyzed with the MHE method. Next, the analyte’s total peak area was determined and the analyte’s concentration in the sample was also measured by comparing against this response factor. PerkinElmer’s Excel® macro was used to make the required measurements for MHE (Figure 2), and it was observed that the sample had 1726µg/kg of MMA.

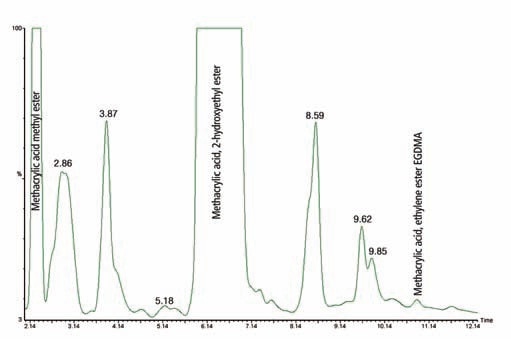

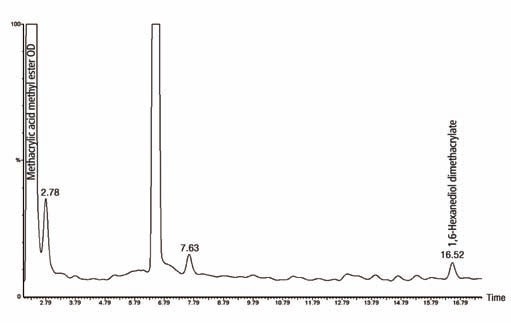

In this application, two samples of polycarbonate lenses were analyzed, both demonstrating MMA peaks. During standard analysis of the polycarbonate polymer, the formula from a prior sample can be utilized, and the number of extraction steps can be brought down. This is an acceptable practice because under given experimental conditions, the matrix will behave in an expected manner. When the number of extraction steps is reduced, the analytical cycle time is increased significantly, and precise calibration of complete extraction is obtained. Two MMA-containing samples of eye-glass lenses were also examined, as shown in Figures 3 and 4.

Figure 3. Chromatogram of Sample 1, demonstrating methacrylic acid methyl ester, methacrylic acid-2-hydroxyethyl ester, and methacrylic acid ethylene ester.

Figure 4. Chromatogram of Sample 2, demonstrating methacrylic acid methyl ester and 1,6-hexanediol dimethacrylate.

Conclusion

The MHE serves as a suitable method for studying residual monomers in polymeric materials. The introduction of headspace sample not only reduces the sample preparation time to a large extent, but also prevents the need for solvents. In this analysis, an automated MHE method is used instead of the complex matrix matching of calibration standards. Furthermore, individual analyte identification is facilitated by mass spectral characteristics. Here, a simple but effective headspace-GC/MS method was used for qualitative and quantitative analysis of several samples.

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer.

For more information on this source, please visit PerkinElmer.