The permitted sulfur levels in petroleum products as per international legislation have been decreasing since the 1990s. The EU Directive 2003/17/EC that came into effect in January 2009 is the latest and the most rigid. According to this directive, the allowed sulfur content in diesel and petrol is only 10mg/kg. ISO and ASTM have also revised their standard test methods to D2622-10 and 20884 for petrol and diesel in accordance with the EU directive. This article demonstrates the suitability of using the Zetium spectrometer to adhere to all of the requirement criteria for D2622-10, which includes the sensitivity and repeatability requirements.

Instrumentation

The experimental set up consisted of a Zetium wavelength dispersive XRF spectrometer (Figure 1) that was configured using a 1kW Rh anode SST R Tube. The set up is a comprehensive system that includes an X-Y sampler handler and unique SuperQ Software that features an advanced Fundamental Parameters algorithm. Zetium has been designed to provide unparalleled analytical precision, accuracy and operational performance.

Figure 1. The Zetium wavelength dispersive XRF spectrometer

Sample Preparation and Measurement

The preparation of commercially available standards and diesel road fuel sample was done based on the D2622-10 test method. About 10 gms of the sample was taken into a disposable liquid cell made of 3.6 µm Mylar film measuring 38 mm for each measurement.

Precision and Instrument Stability

Zetium exhibits high repeatability and precision. The test results are summarized in Table 1.

Table 1. Analytical precision for sulfur analysis (20 consecutive measurements)

| REPEATABILITY (n = 20) |

| Mean (mg/kg) |

6.4 |

| RMS (mg/kg) |

0.11 |

| RMS (rel. %) |

1.74 |

| COUNTING STATISTICAL ERROR |

| CSE (mg/kg) |

0.25 |

| CSE (rel. %) |

0.65 |

| STATISTICAL COMPARISON OF REPEATABILITY |

| This study |

0.35 |

| Norm requirements |

0.65 |

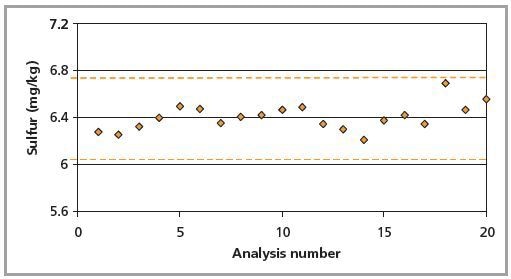

The repeatability measurements of sulfur as per ASTM D2622-10 test are presented in Figure 2. The repeatability measurements of diesel road fuel sample with a sulfur content of 6.4 mg/kg along with the limits for ASTM D2622-10 are also shown in the figure.

Figure 2. Repeatability measurements of sulfur measurements according to ASTM D2622-10. Dashed lines indicate the precision set in the method.

The D2622-10 repeatability criterion is that consecutive test results should not exceed the specified limits for more than one in 20 cases. The following equation provides the ASTM D2622-10 test method limit:

Repeatability (r) = 0.1462* mean (mg/kg)0.8015

Accuracy

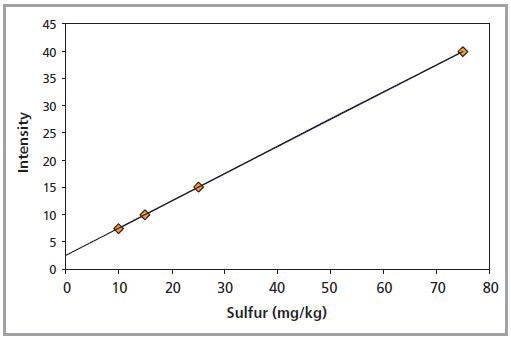

Figure 3 shows the accuracy of the calibration. It can be seen that the calibration RMS value of 0.87 mg/kg is in accordance with the comparison between the certified chemical concentrations and the concentrations obtained from the regression.

Figure 3. Calibration plot for sulfur in oil analyzed according to ASTM D2622-10.

An independent check was performed on a sample of diesel fuel with a known sulfur content of 12 mg/kg to verify the accuracy of the calibration. The sulfur content obtained from the experiment was found to be the same as the expected 12 mg/kg.

Detection limits

Table 2 provides the lower limits of detection (LLD) for sulfur.

Table 2. Detection limits of sulfur in diesel fuel

| Detection limit (mg/kg) |

ASTM D2622-10 diesel fuel, 3.6 μm Mylar |

| LLD (100 s) |

0.36 |

This testing method is also suitable for detecting sub-mg/kg detection limits for comparatively short measurement times. For instance, LLDs of 1 mg/kg can be achieved in measurement times of 12 seconds.

Conclusion

The XRF method for analyzing the sulfur content is a comparatively simple technique, and provides quick results. Based on the data obtained, the accuracy and precision of Zetium in sulfur analysis are validated. Zetium also meets the stringent requirements of international test methods like D2622-10 and ASTM. The capability of the Zetium spectrometer in detecting sub-mg/kg limits makes it suitable to fulfill the current requirements of the industry and of rigorous legislative regulations that are likely to be enforced in the future.

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical.

For more information on this source, please visit Malvern Panalytical.