Chocolates have a unique mouthfeel and occupy a special place in the western palate. The mouthfeel depends on the fat phase composition in the chocolate, as well as to the size of milk, cocoa, and sugar particles that are suspended in the fat. Chocolate manufacturers have done extensive consumer research, which show that when the size of the particles is above 30 µm consumers do not experience the unique mouthfeel, and rate the chocolate to be of inferior quality.

The Importance of Particle Size in Chocolate

The texture of the end product is determined by the particle size and can be controlled with two milling steps: grinding and conching. These methods can be expensive and take significant amount of time and energy. So if there are techniques that can control the particle size more effectively, there help ensure the quality of products. One such technique is provided by the Mastersizer 3000, a laser diffraction instrument, which can be used to determine the particle size at various stages of the manufacturing process.

In the past chocolate manufacturers faced a number of problems when it came to adding milk to chocolates. This is because milk is a seasonal product, and was always in huge demand during the Christmas season. Milk substitutes like dried milk powder and the use of crumb provide a suitable solution to this problem. Crumb has composite particles and is made by drying sugar, milk, and cocoa solids together. This mixture is later stored for use throughout the year. However it can be expensive to make crumbs, and fresh milk is now available at all times of the year. When compared to the powder process, the crumb has a unique flavor profile, and is still used in certain brands to retain their classic flavor. This article demonstrates the measurement of the particle size distribution of dark, white and milk chocolates, and makes a comparison of particle size distributions between powder and crumb milk chocolates.

Materials and Methods

In order to analyze the particle size distribution in different types of chocolates, a single brand of dark, white and milk chocolates were selected to reduce differences in the chocolate manufacturing process, as well as in ingredient variation. Table 1 shows the main ingredients of dark, white and milk chocolates. Using an ultrasound the chocolate samples were pre-dispersed, and measurements were performed using the Mastersizer 3000 with Hydro MV dispersion unit.

Table 1. The particulate ingredients in different types of chocolate.

| |

Cocoa solids |

Sugar |

Milk powder |

| Dark |

Y |

Y |

|

| Milk |

Y |

Y |

Y |

| White |

|

Y |

|

Findings

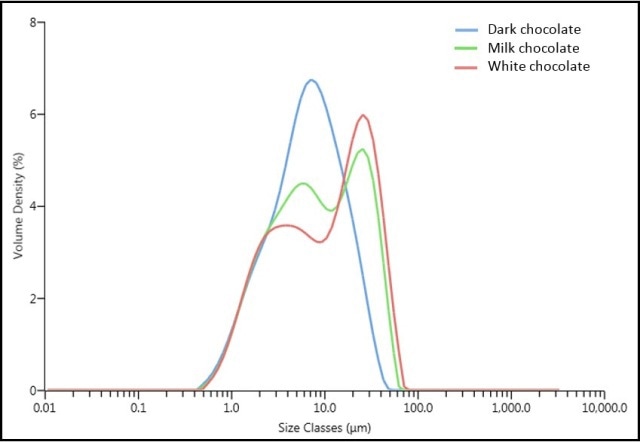

It was observed that all three types of chocolate had varied particle size, as shown in Figure 1. There are common features, such as a mode of huge particles measuring about 30 µm, and a mode of smaller particles measuring approximately 5 µm. The mode of 30 µm exists as a slight shoulder in the case of dark chocolate. The ratio of these modes differs with each chocolate type, and may be correlated to the presence and amount of varied ingredients. A large mode is relative to the increasing amounts of sugar content from dark to milk to white chocolate. Since dark chocolate has smaller amounts of these large particles, it appears to have a smoother, luxurious texture compared to other chocolates.

Figure 1. The particle size distributions of different types of chocolate made by one Manufacturer.

The proportion of particles above 30 µm for different types of chocolates is illustrated in Table 2. As displayed in Table 2, Dv50 µm and Dv90 µm show the increase in particle size from dark to milk to white chocolate, while Dv10 µm does not vary considerably. Chocolate manufacturers aim to detect the presence of large particles, and the important parameter in the measurement of particle size is often Dv95 or even Dv98 where considerable differences between the types of chocolates can be detected. On the other hand, the proportion over 30 µm can be directly obtained from the analysis.

Table 2. The percentiles and proportion of particles above 30 µm for different types of chocolate.

| |

Dv10 (µm) |

Dv50 (µm) |

Dv90 (µm) |

Dv95 (µm) |

Dv98 (µm) |

>30µm |

| Dark |

1.74 |

6.62 |

19.5 |

24.5 |

30.3 |

2.13% |

| Milk |

1.77 |

8.32 |

32.5 |

39.2 |

46.0 |

12.56% |

| White |

1.77 |

10.8 |

37.0 |

44.4 |

52.2 |

17.32% |

Particle Size in Powder and Crumb Milk Chocolates

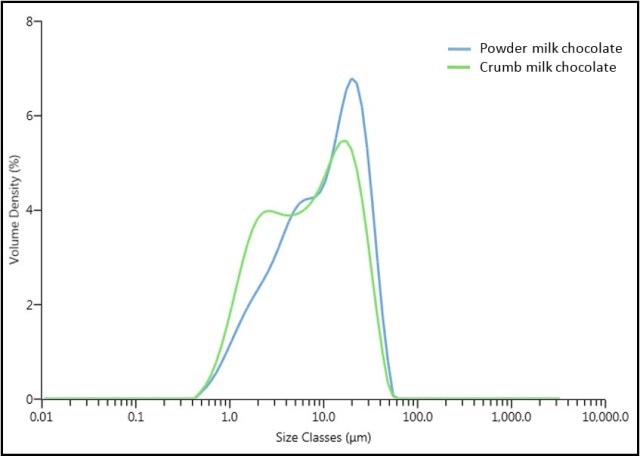

Figure 2 shows the particle size distributions from crumb and powder milk chocolates made by the same manufacturer, and Table 3 lists the statistics of the particle size for both crumb and powder milk chocolates.

Figure 2. The particle size distributions of powder and crumb milk chocolates made by one Manufacturer.

Table 3. The percentiles and proportion of particles above for powder and crumb milk chocolates.

| |

Dv10 (µm) |

Dv50 (µm) |

Dv90 (µm) |

Dv95 (µm) |

Dv98 (µm) |

>30µm |

| Powder |

1.93 |

10.5 |

29.3 |

34.7 |

40.4 |

9.21% |

| Crumb |

1.48 |

7.22 |

25.0 |

30.6 |

36.8 |

5.43% |

The multimodal particle size distribution depicts the mixed material nature of chocolate. However the two main modes are much closer together in powder chocolate, compared to the crumb chocolate. Powder chocolate exhibits a tail of fine lines, not seen in the crumb version. These features contribute to particle size distribution, imparting a unique texture to the powder and crumb chocolates. The difference in these features is due to the varied recipe and processing routes. With a lower Dv90 than that of the powder chocolate, the crumb chocolate will be deemed as a finer chocolate by consumers. These features may be either related to the textures and flavor profiles corresponding to a particular brand, or it may represent the actual quality of the chocolate.

Since the composite particles present in the crumb enter the process with a larger particle size in comparison to the milk powder, the grinding process is likely to be longer and more costly for crumb chocolate.

Conclusion

It is evident that the quality of the chocolate is affected when the particle size is more than 30 µm. For quality production of chocolates, laser diffraction is as a suitable tool to detect changes in the particle size with regard to the chocolate manufacturing processing and the type of product produced. Using this instrument, particle size above 30 µm can now be easily determined.

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical.

For more information on this source, please visit Malvern Panalytical.