Benzene’s actionable level at the refinery fenceline has been reduced to 9.0 µg/m3 (2.8 ppb) with recent amendments to 40 CFR 60 and 63 compliance. Process Insights’ MAX300-AIR is an environmental mass spectrometer that provides a fully automated, real-time analysis of benzene. It also eliminates the need for manual sampling with reduced annualized expenditure (Figure 1).

Figure 1. The MAX300-AIR, real-time mass spectrometer, configured for benzene fenceline monitoring

Instrument for Oil Refinery Fenceline Compliance

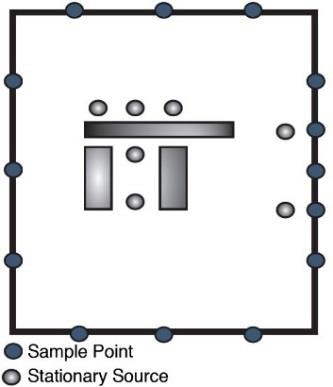

The MAX300-AIR gas analyzer can determine benzene in air at less than 0.3 µg/m3 (0.1 ppb). Its sensitivity and speed make it a suitable instrument for oil refinery fenceline compliance (Figure 2).

Figure 2. According to regulation, sample points may be placed on the fenceline, or along a smaller perimeter that encloses every stationary source.

Air is continuously pulled from individual sample points to the MAX300 instrument for analysis, and the concentration of benzene is reported to the data system of the refinery all in a matter of a few seconds. Samples are not contaminated during transport and handling, and there is also no need to procure thermal desorption GC-MS systems, or to pay for third-party lab analysis. Furthermore, personnel do not have to physically collect passive diffusion tubes.

Specifications

Specifications of the MAX300-AIR real-time gas analyzer are as follows:

- Benzene low detection limit < 0.3 µg/m3 (0.1ppb)

- 24/7 automated fenceline monitoring

- No need for lab analysis or manual sample collection

- Low annualized cost

- > 99% demonstrated uptime

- Real-time benzene alerts for easy detection of source

- Can determine additional required volatile organic compounds (VOCs)

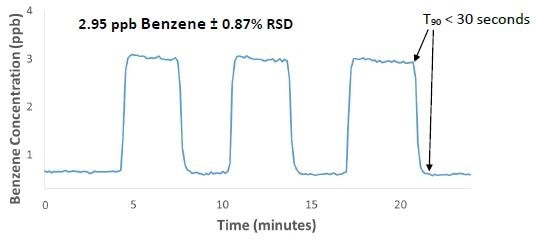

Quantitation at Trace Concentrations

The MAX300-AIR mass spectrometer is capable of reporting the presence of 9.0µg/m3 (2.8ppb) benzene within a span of seconds, and has the required accuracy to allow confident quantitation at trace concentrations much below the EPA actionable level (Figure 3).

Figure 3. The MAX300-AIR performance on 2.95ppb benzene. The sample alternates between air and a certified bottle of air containing 9.5µg/m3 (2.95ppb) benzene.

The refinery would instantly know when a benzene spike is detected and can subsequently detect the source easily and precisely, without having to maintain weeks of detailed notes on the operation of the plant. For personnel and the surrounding community, real-time monitoring is relatively safer. Such monitoring, combined with wind direction, can quickly point to transient benzene from adjacent industrial facilities, rail lines, highways, etc.

With more and more compounds being included in fenceline regulations, such regulations can be added to the MAX300 analysis technique without any need for hardware changes. The following table shows a comparison of fenceline technologies.

Table 1. A comparison of fenceline technologies

| Monitoring option |

Benzene update rate |

Manual sample collection |

Annualized cost |

Additional laboratory investment |

Performance unaffected by weather (rain, fog, wind)? |

Can easily measure additional VOCs? |

| MAX300-AIR, environmental mass spectrometer |

Real-time |

None, automated continous |

$5,000 |

None |

Yes |

Yes |

| Open-path monitoring (UV-DOAS, FTIR) |

Real-time |

None, automated continous |

>> $40,000* |

None |

No |

No |

| Passive diffusion tube monitoring network |

1 update every 2 weeks |

26 x per year |

$40,000* |

Thermal desorption GC-MS, labor, or third-party analysis |

No |

No |

*Annualized costs are based on data from Fenceline Monitoring Technical Support Document, in Docket ID Number EPA-HQ-OAR-2010-0682

Conclusion

For more than five decades, Process Insights has provided optimum support to the industry, and has deployed a countless number of emissions and environmental analyzers at sites across the globe.

This information has been sourced, reviewed and adapted from materials provided by Process Insights - Mass Spectrometry.

For more information on this source, please visit Process Insights – Mass Spectrometers.