Strongwell manufactures EXTREN®, the highest quality pultruded fiberglass structural shapes available (Figure 1). Extren is achieved through the combination of composite design, superior raw materials, and the pultrusion process.

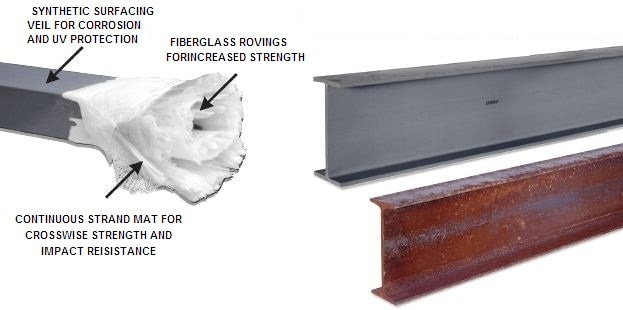

Figure 1. Extren is the highest quality pultruded fiberglass structural shapes available.

EXTREN® Fiberglass Structural Shapes

EXTREN® fiberglass structural shapes have strength superior to steel on a pound-for-pound basis in lengthwise direction, and are one-fourth the weight of steel (Figure 2). They exhibit outstanding corrosion resistance to most salts, caustics, and acids. They also offer long-term, economical solutions as they require low maintenance.

Figure 2. EXTREN® fiberglass structural shapes weigh 25% as much as steel

Other key features of the EXTREN® fiberglass structural shapes include:

- EMI/RFI transparent

- Dimensionally stable

- Fire retardant as a fire retardant premium polyester or vinyl ester resin system can be utilized by EXTREN®

- Consists of UV inhibitors

- It is possible to custom manufacture EXTREN® in special colors

Extren Vs Steel

The following table provides a comparison between Extren and steel (Figure 3):

Figure 3. Unlike steel, which will rust when exposed to weathering and chemicals, EXTREN® fiberglass structural shapes are highly corrosion resistant.

| Features |

EXTREN® Fiberglass Structural Shapes |

Steel A-36 Carbon |

| CORROSION RESISTANCE |

EXTREN® is available in either polyester or vinyl ester resin for resistance to a broad range of chemicals.

Painting may be necessary when exposed to direct sunlight to prevent color fading. |

Subject to oxidation and corrosion.

Requires painting or galvanizing for many applications. |

| WEIGHT |

Lightweight — weighs 25% as much as steel.

1/2" thick plate = 4.7 lbs./sq. ft. |

Could require lifting equipment to move and place.

1/2" thick plate = 20.4 lbs./sq. ft. |

| CONDUCTIVITY |

Low electrical conductivity properties — high dielectric capability.

Low thermal conductivity 4 (btu/sf/hr/f°/in). |

Conducts electricity. Potential Shock Hazard.

Thermal Conductivity 260-460 (btu/sf/hr/f°/in). |

| STRENGTH |

EXTREN® has a high strength-to-weight ratio and pound-for-pound is stronger than steel in the lengthwise direction.

Tensile Strength = 30 ksi, cw = 7 ksi |

Homogeneous material.

Tensile strength = 60 ksi

Yield strength = 36 ksi |

| STIFFNESS |

Modulus of Elasticity = 2.5 Msi

Will not permanently deform under working load. |

Flexural modulus = 29 ksi

Modulus of Elasticity = 29 Msi |

| IMPACT RESISTANCE |

Glass mat in EXTREN® distributes impact load to prevent surface damage. Will not permanently deform under impact. |

Can permanently deform under impact. |

| EMI/RFI TRANSPARENCY |

Transparent to EMI/RFI transmissions. |

Can interfere with EMI/RFI transmissions. |

| VERSATILITY |

Pigments added to the resin provide color throughout the part. Special colors available. |

Must be painted for color. To maintain color and corrosion resistance, repainting may be required. |

| EASY FIELD FABRICATION |

EXTREN® can be field fabricated using simple carpenter tools with carbide or diamond tip blades.

Lightweight for easier erection and installation. |

Often requires welding and cutting torches.

Heavier material requires special handling equipment to erect and install. |

| COST |

Lower installation and maintenance costs in industrial applications often equals lower lifecycle costs. |

Lower initial cost. |

This information has been sourced, reviewed and adapted from materials provided by Strongwell Corporation.

For more information on this source, please visit Strongwell Corporation.