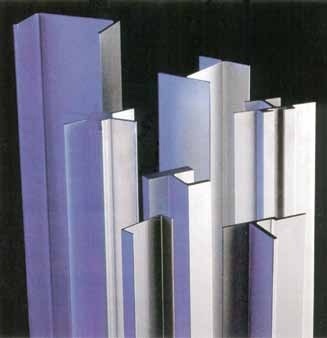

EXTREN® from Strongwell is a proprietary combination of thermosetting polyester or vinyl ester resin systems and fiberglass reinforcements. It is fabricated in over 100 standard shapes (Figure 1).

Figure 1. EXTREN® fiberglass structural shapes and plate

Advantages of EXTREN®

EXTREN® fiberglass structural shapes and plates are advantageous in many ways over aluminum (Figure 2).

Figure 2. Typical aluminum shapes extruded from aluminum billets

The following are the key advantages of EXTREN® (Figure 3):

- Lightweight

- Thermally and electrical nonconductive, a key safety feature

- Strong

- Impact resistant

- Highly corrosion resistant

- EMI/RFI transparent

Figure 3. EXTREN® fiberglass structural shapes and plate have a number of significant advantages over aluminum.

EXTREN vs. Aluminum

The key features of EXTREN® fiberglass structural shapes are compared against aluminum extruded shapes in the following table:

| Features |

EXTREN® Fiberglass Structural Shapes |

Aluminum Extruded Shapes |

| CORROSION RESISTANCE |

Superior resistance to a broad range of chemicals.

Surfacing veil and UV additives improve weatherability. |

Can cause galvanic corrosion.

Corrosion resistance can be increased through anodizing or other coatings. |

| WEIGHT |

Very lightweight — about 80% the weight of aluminum. |

Lightweight - about 1/3 that of copper or steel. |

| ELECTRICAL CONDUCTIVITY |

Insulates — low thermal conductivity (4 btu/sf/hr/f°/in); low thermal coefficient of expansion (7 (in/in/f°)106). |

Heat conductor — high thermal conductivity (150 btu/sf/hr/fo/in); thermal coefficient of expansion 11-13 (in/in/f°) 106. |

| STRENGTH |

Ultimate flexural strength (Fu) lw = 30 ksi, cw = 10 ksi.

EXTREN® has 86% of the yield strength of aluminum and pound-for-pound, is stronger than aluminum in the lengthwise direction. |

Flexural strength (Fu) 35 ksi.

Homogeneous material. |

| FINISHING AND COLOR |

Pigments added to the resin provide color throughout the part. Special colors available. Composite design can be customized for required finishes. |

Silver color. Other colors require prefinishes, anodic coatings and paints. Mechanical, chemical and electroplated finishes can be applied. |

| EMI/RFI TRANSPARENCY |

Transparent to radio waves, EMI/RFI transmissions; used for radar and antennae enclosures and supports. |

Highly reflective. |

| FABRICATION |

Easy field fabrication with simple carpenter tools — utilizes adhesive bonding and/or mechanical joining. No torches or welding. |

Good machinability — welding, brazing, soldering or mechanical joining. |

| COST |

Slightly higher tooling costs; price per lineal foot marginally higher. |

Extrusion tooling is relatively inexpensive. Part price comparable or slightly lower. |

| IMPACT RESISTANCE |

Glass mat in EXTREN® distributes impact load to prevent surface damage even in sub-zero temperatures. Will not permanently deform under impact. |

Easily deforms under impact. |

This information has been sourced, reviewed and adapted from materials provided by Strongwell Corporation.

For more information on this source, please visit Strongwell Corporation.