Biopharmaceutical and medical device manufacturers have to meet the strictest standards for purity and sanitation in the industry. In order to match the ever-growing demand, maximizing productivity without increasing the cost factor is a key requirement for such companies.

Materials that are widely used in production and diagnostic applications are not able to meet the lifetime and performance required for the end user's ideal workflow. Damaged or worn componentry, frequent cleaning, and corrosion from bleach affect both output and profitability.

SilcoTek® provides advanced coatings that not only improve the service life and performance of products but also make them work faster. The nano-scale coating of elemental silicon, oxygen, and carbon created by the chemical vapor deposition (CVD) process provides better chemical resistance than stainless steel with durability and functionality superior to fluoropolymers.

Material Challenges in Medical and Biopharma Industries

The following are the key material challenges in biopharma and medical industries:

- Frequent maintenance: Proteins and other biomolecules tend to adsorb onto stainless steel surfaces, requiring manual maintenance, long delays, and component replacement

- High costs from corrosion: Even super-austinitic grades of stainless steel corrode and threaten the purity of products, especially when bleach is commonly used in cleaning cycles.

- Poor reliability: Metal ions from stainless steels leach into process streams, whereas delamination is the major problem with polymer coatings during regular maintenance, leading to false results or upsets

Problems Solved by SilcoTek® Coatings

The advanced coatings from SilcoTek® address the following problems:

- High costs because of corrosion, especially from bleach

- Contamination caused by leaching of metal ions out of equipment

- Poor performance due to sticking of proteins

- Unreliable analytical results because of chemical reactivity

- Recurring replacement due to material wear

Applications of SilcoTek Coatings

SilcoTek coatings improve the performance in the following applications:

- Reaction and mixing

- Consumable disposal

- Mass spectroscopy

- Medical devices

- Liquid chromatography

- Immunoassay analysis

Common components that benefit from SilcoTek® coatings include needles, sensors, probes, valves, tubing, fittings, vessels/reactors, and consumables.

Advanced Surfaces for Advanced Performance

SilcoTek’s patented coatings are advantageous in many ways over alternatives, providing superior performance and flexibility in system design, production, and installation to medical device and biopharma manufacturers.

Innovative Deposition Process Makes Integration Easy

In the gas-phase CVD process, the coating is bonded to the molecular structure of the base substrate, creating a flexible layer that is bendable without flaking like polymers such as PTFE. Also, narrow internal passageways and other intricate geometries can be thoroughly coated with ease.

SilcoTek improves parts made of stainless steel, ceramics, glass, and more, even those with complex geometries or high aspect ratios

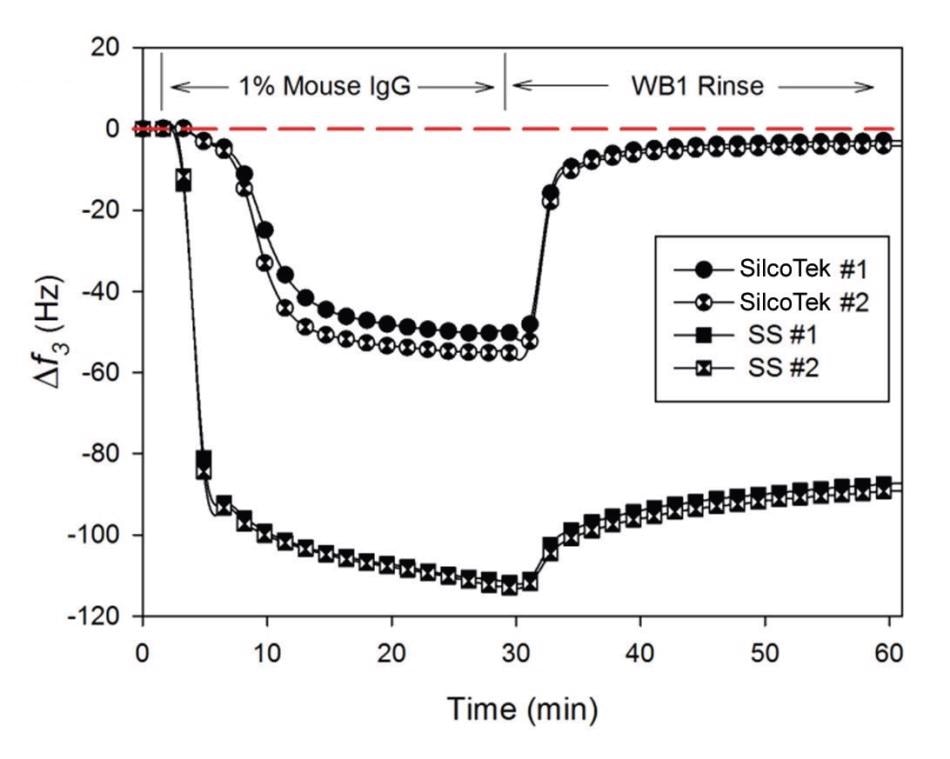

Low Surface Energy Prevents Protein Sticking

In the medical industry, preventing non-specific adsorption of proteins to surfaces is highly desirable. SilcoTek coatings create a robust, low energy surface, which prevents moisture, proteins, and more from being retained. Consequently, analytical results are improved, leading to a much higher throughput.

SilcoTek-coated stainless steel shows superior protein resistance as well as durability against routine cleaning and maintenance procedures, compared to typical solutions like fluoropolymers.

1SilcoTek coatings enable better diagnostic results and decrease maintenance by greatly reducing protein sticking

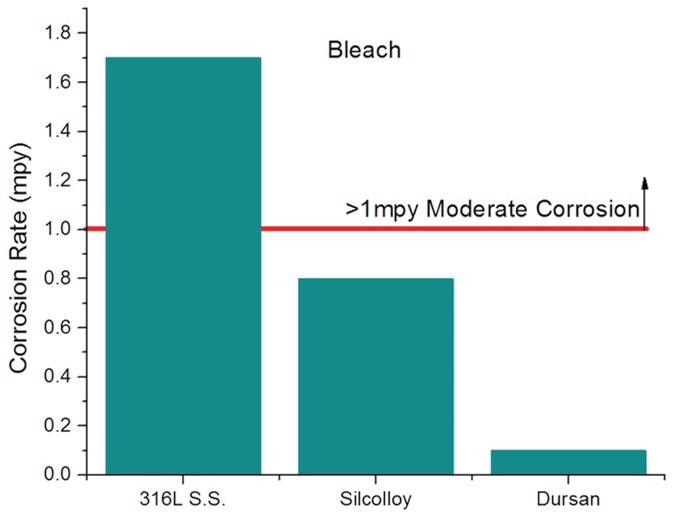

Superior Corrosion Protection for Longer Usable Life

The corrosion resistance of alloys such as stainless steel can be significantly improved using SilcoTek coatings, ensuring purity and sanitation.

SilcoTek coatings substantially improve the corrosion resistance of stainless steel and other alloys, ensuring purity and sanitation.

SilcoTek coatings (right) allow the use of concentrated bleach without any of the corrosion issues that are common with bare stainless steel

Conclusion

SilcoTek provides a unique service experience that gives priority to customers and the quality of their components. The company is committed to providing fast, superior quality, error-free coatings every day.

Reference

1 Vaidya, S., Yuan, M., Narváez, Daghfal, D., Mattzela, J., Smith, D. “Protein-resistant properties of a chemical vapor deposited alkyl-functional carboxysilane coating characterized using quartz crystal microbalance.” Published in Applied Surface Science. December 2015.

This information has been sourced, reviewed and adapted from materials provided by SilcoTek.

For more information on this source, please visit SilcoTek.