eldec generators provide excellent technical properties for the induction heating of metals. Induction heating is a very precise and quick process, as heat is applied selectively to the parts of the workpiece where heat treatment is desired. Induction is generally suitable for all electrically conductive materials.

Induction Heating – The Efficient Way to Accurately Heat Metals

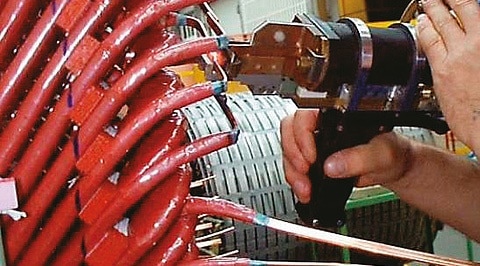

All induction heating processes, including induction welding, induction brazing, induction annealing, induction tempering, induction hardening, and other hot forming technologies, are based on the laws of induction. eldec generators have been specifically designed for induction heating. The comprehensive product portfolio of induction generators from eldec provides the optimum solution for a wide variety of applications.

What is Induction Heating? How Does Induction Heating Work?

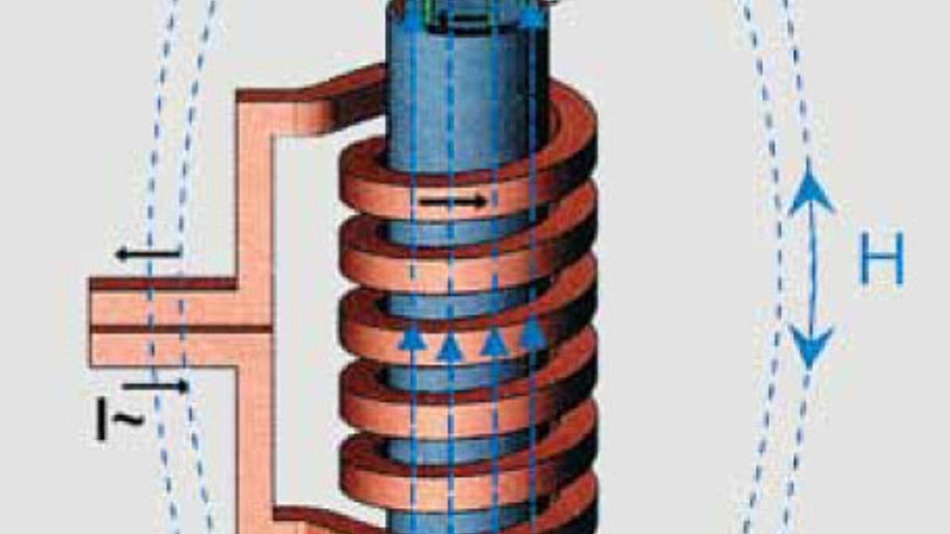

During induction heating, an alternating electromagnetic field induces eddy currents in an electrically conductive metallic workpiece. The eddy currents are then converted into heat by magnetic loss. Or, simply put, the metal heats up because of the current flow generated in the workpiece.

This allows induction heating to introduce heat directly into the workpiece, instead of through connectivity from external sources such as heating with a furnace or a flame. Therefore, this process achieves a very high degree of efficiency. Heating can also be achieved passing through non-conductive materials. The surrounding area is only heated indirectly.

Influences on Induction Heating

The depth of heating of the workpiece relies on the material properties of the workpiece. It is also influenced by the frequency of the current supplied by the generator. Higher frequencies are particularly suitable for heating contours very accurately at a low depth of penetration in the workpiece, and lower frequencies are ideally suited for a higher depth of penetration.

Therefore, depending on the task, an in-depth analysis needs to be carried out to select the optimal generator for the induction heating task. Next to the inductor, the frequency is one of the major criteria for a successful induction heating process. However, the design of an induction heating solution is also greatly influenced by other factors such as the material, production batch sizes, and heating temperature.

eldec offers generators for induction heating for the following materials:

- Iron

- Steel

- Copper

- Copper alloys

- Aluminum

- Brass

- Stainless steel

- Hard metals

- Tungsten

- Nickel

- Chrome

- Nickel alloys

- Precious metals

- Cobalt

- Silver

- Graphite

- Carbon fiber

- Platinum

- Silicium

This information has been sourced, reviewed and adapted from materials provided by Eldec Induction USA, Inc.

For more information on this source, please visit Eldec Induction USA, Inc.