Induction brazing has many benefits over furnace or flame brazing. This technology provides precise, fast, and reproducible heat input and reliability. eldec offer generators that are perfectly adapted to the needs of induction brazing.

Induction Brazing is Ideally Suited for High Volume Production

Compared to heating by flame or in a furnace, soldering or brazing applications involve considerably faster heating times. Also, the induction process creates heat within the parts, in contrast to heating in a furnace or by flame where only the surface is heated by convection.

Induction heating of workpieces is faster than heating by traditional methods. In order to ensure fast and controlled heating, precisely controlled, powerful generators are needed.

With the series of MICO, PICO, ECO LINE and CUSTOM LINE generators, eldec offers a perfect product range for induction brazing. All sources of energy provided by eldec can be controlled with respect to temperature, current, and power, making it possible to respond to the individual needs and environmental conditions of each process.

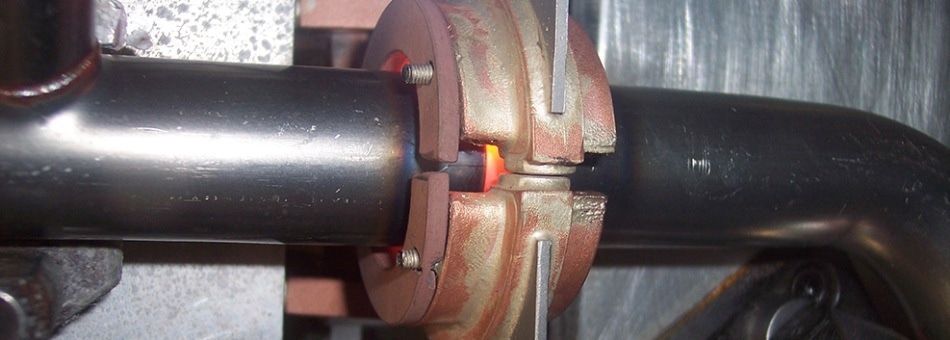

A unique feature of induction brazing is the ability to selectively heat components and workpieces for brazing purposes, without causing any major impact on the surrounding components. Induction brazing is also suitable for areas that need secure, high-quality joining and are difficult to access. Induction brazing is suitable for high-volume production, as consistent heat input is provided through the precise energy metering by eldec generators.

Eldec Offers Solutions for Induction Brazing for the Following Materials

Eldec provides solutions for induction brazing of brass, iron, steel, stainless steel, copper, copper alloys, aluminum, and all types of carbides. Also, induction brazing can be used to join materials such as cobalt, chromium, tungsten, precious metals, nickel, and nickel alloys.

Overview of the Benefits of Induction Brazing

- Immediately ready for operation – the high performance of eldec generators readily provides the required power to start brazing

- Consistent heat input provides excellent brazing quality. The basis is offered by processor-controlled eldec generators

- Minimal wear of inductors – the heating process by induction brazing does not need any contact between the workpiece and the inductor

- Suitable for serial production, thanks to precise process repeatability

- Safe and easy application of induction brazing – the heat input for induction brazing can be controlled easily and with excellent precision

- Maximum safety of induction brazing – the induction brazing process does not involve any open flame or fuel gas. Selective heating is directly targeted at the preferred area of the workpiece

- Minimized energy requirements – during pause intervals or waiting times, eldec generators require almost no energy (except standby power for the control system). Induction brazing can be restarted instantly, without any delay or warm-up period

- Reduction of cold brazing joints – during induction brazing, heat input occurs directly without negatively affecting the base material (reproducible)

- Reduction of weak brazing joints and porosity, due to reliable and precise process control, such as time and power

Use of Induction Brazing

Induction brazing is used in the following sectors:

- Aerospace industry

- Automotive industry

- Electrical engineering

- Toolmaking industry

- Home appliance industry

- Air conditioning industry

- Fittings industry

- Generator construction/power plant construction

eldec sample applications for induction brazing are as follows:

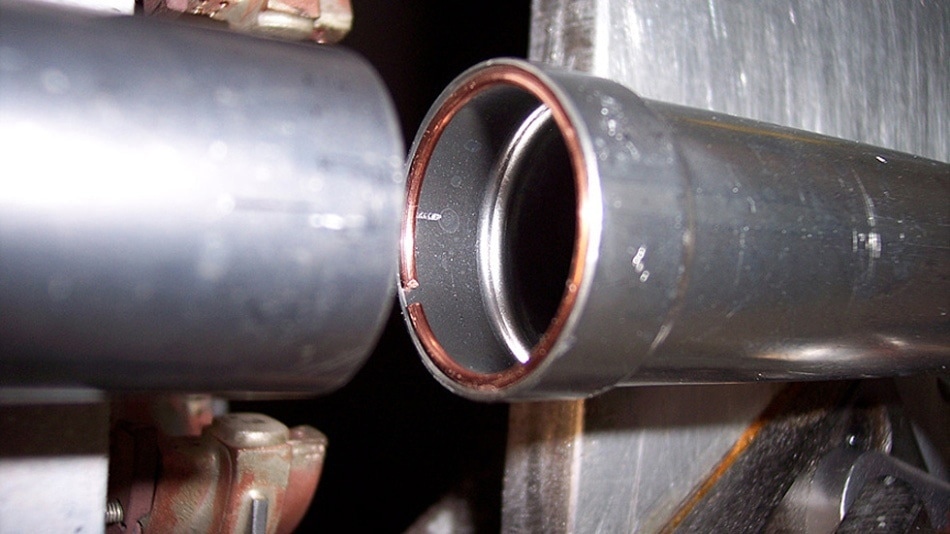

- Induction brazing of copper profiles

- Induction brazing of short-circuit rings

- Induction brazing (application by brazing) of carbide cutting tips

- Induction brazing (application by brazing) of carbide pins

- Induction gas-shielded brazing

- Induction brazing of heat exchangers

- Induction brazing of copper wires

This information has been sourced, reviewed and adapted from materials provided by Eldec Induction USA, Inc.

For more information on this source, please visit Eldec Induction USA, Inc.