Apr 19 2002

Wikimedia Commons

The basis of the nickel-titanium shape memory alloy (SMA) class is the intermetallic equiatomic binary alloy NiTi. Thanks to its moderate solubility range, its composition can be changed, and it can be alloyed with other elements to alter both mechanical and shape memory properties.

The nickel-titanium alloy exhibits common shape memory behavior and is restored to its original shape after it is heated more than its phase transformation temperature.

When heated to this temperature, the alloy transforms from its low-temperature monoclinic martensitic structure to the high-temperature cubic austenitic structure.

History

Although the first shape memory alloy was discovered in 1932, the nickel-titanium SMAs were first discovered by Buehler only in the early 1960s. The name “Nitinol” was coined as he was working at the Naval Ordinance Laboratory at that time.

Buehler’s discovery was the foundation for the very first commercially developed shape memory alloy.

Compositional Variations

The basis of several Nitinol alloys is the equiatomic composition.

The most general way of modifying Nitinol alloy is by including additional nickel up to an extra 1%. This process not only increases the yield strength of the austenitic phase but also brings down the transformation temperature.

Other common additives, such as iron and chromium, are added to modify the phase transformation temperature, which reduces the temperature. In addition, copper can be added to minimize the stress needed to deform the martensitic phase, which also reduces the hysteresis.

Carbon and oxygen are contaminants that must be eliminated from the system. They can affect the mechanical properties and have an impact on the transformation temperature.

Work Hardening and Two-Way Shape Memory Effect

Work hardening and appropriate heat treatment can be carried out to decrease the deformation stress. This process not only enhances the strength of the austenitic phase but also gives two-way shape memory effect to the alloy.

Properties

The composition of Nitinol alloys governs their properties, which can also be affected by other factors like heat treatments. However, the density of a majority of the Nitinol alloys is around 6.5 g/cm3 and their melting temperature ranges from 1240 °C to 1310 °C. The transformation temperature can be changed from less than −100 °C to more than 100 °C.

Listed below are the significant properties of Nitinol alloys:

- Biocompatible

- Huge forces can be produced as a result of the shape memory effect

- Moderate resistance to impact

- Excellent resistance to corrosion

- Exhibit outstanding damping properties below the transition temperature

- Non-magnetic by nature

- Exhibit high fatigue strength

- Moderate resistance to heat

Applications

- Medical applications—Stents for cardiovascular applications, tweezers for eliminating foreign objects through small incisions, and anchors for tendon fixation

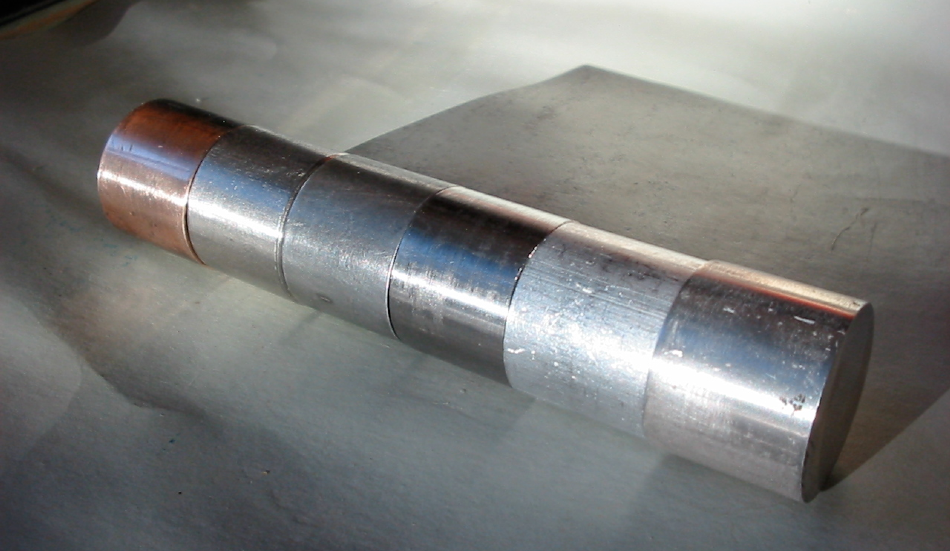

- Aerospace and naval applications—Couplings and fluid fittings made of Nitinol are utilized in naval craft and military aircraft

- Safety devices—Fire sprinklers and safety valves/actuators for controlling water temperature

- Dentistry—Orthodontic wires that do not require adjusting and retightening

Following are some of the other uses of Nitinol alloys:

- Deep fryers and household appliances

- Spectacle frames

- Vibration control when used as engine mounts, and actuators for buildings

- Mobile telephone antennas

- Seals, fasteners, clamps, and connectors

- Clothing such as underwire brassiere