Users can achieve a more efficient purification with reduced cost through peak recycling. This article explains when peak recycling is viable and what technical specification is required for this process.

Shutterstock | Rueangwit

In simple terms, peak recycling elongates the separation length of a column by using the length of the column bed multiple times. Many users of preparative chromatography are aware of the term, but they do not know precisely where this special solution will be useful.

At the time of peak recycling, the peaks are led back onto the column following elution, so that critical peak pairs running together can be further separated with each cycle. Since the eluent composition has to remain constant during multiple repetition cycles, an isocratic separation method is required for peak recycling.

A preparative HPLC system is made up of a detector, a preparative column, a preparative pump, a fractionation valve, and an injection system.

Chromatography columns used for preparative applications are usually very expensive. Therefore, users strive to find the best compromise between the achieved separation efficiency and incurring costs. Thus, both the individual separation challenge and the purification requirements set the conditions. This is the reason why complex separation challenges can result in cost-ineffective solutions and high expenses.

In particular cases where small particle sizes or special phases are needed for an efficient purification, both the system requirements and the cost of the preparative column become a limiting factor. Peak recycling provides a simple solution to improve the separation performance without the requirement for larger investments.

Technical Requirements

Generally, the terms “recycling” and “recycling mode” are used to represent different types of recycling:

1. Time-based peak recycling

This is not an automated mode and is used with any chromatography software. However, it is more difficult to configure. Retention time changes within a single separation can produce variations in purity of the collected fractions.

2. Automated peak recycling:

Using this mode, the software can control the recycling by peak height and/or slope. The automated mode (e.g. OpenLAB CDS EZChrom Edition) requires specific software packages to provide a high level of safety and comfort.

3. Solvent recycling:

Software packages, such as PurityChrom or ClarityChrom Prep, provide solvent recycling as an extra option to save solvent. If the solvent present in chromatogram regions without peaks is considered clean, it can be recycled back into the eluent stock, depending on time or detector signal. This mode can significantly reduce the operating costs of a system.

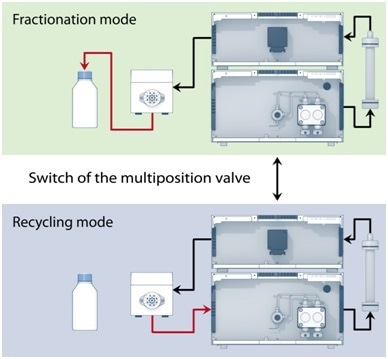

Just a T-fitting and a multi-position valve are needed to use the recycling mode.

The T-fitting connects the multi-position valve to the system pump supply through a port (in many cases, the second last port of the valve). When the system skips from normal to recycling mode, the valve is switched to that particular port. Then, the pump draws the eluent not from the stock but instead it recycles the solvent through the entire system as shown in Figure 1.

Figure 1. Preparative HPLC system with multi-position valve enabling peak recycling.

The samples are pumped in cycles until the valve is switched to either waste or fractionation position.

Application Example

A practical example for the optimization of a separation method using peak recycling is the separation of the two (+/- )-α-Tocopherol isomers.

Compared to analytical HPLC, the potential for optimization is much more limited for preparative HPLC. For preparative applications in reversed phase mode, the option of column material is mostly limited to standard phases with minimum particle sizes of 10 µm. On the other hand, these preparative columns with inner diameters of 20 to 100 mm show a lower separation performance, yet they produce a much lower back pressure at high flow rates, compared to similar columns with small particle sizes.

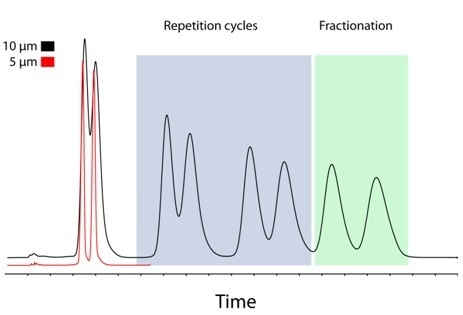

Users who are dealing with a complex separation task like tocopherol, where the target substance elutes narrowly to the contaminant, will have limited options (Figure 2). The required high performance pumps, together with the costs for particular phases leading to better separation, often exceed the benefit. However, a compromise of typically impaired separation performance is not required. If the right technique is used, users can achieve excellent separation results, even with inexpensive large particle materials.

Vitamin E and Tocopherol

Vitamin E consists of a number of fat-soluble substances. It also contains eight variants of Tocopherol, of which only the α-Tocopherol is in active form. In the food industry, only the biologically active forms are relevant.

α-Tocopherol is mostly used as E307 in the food industry and as an ingredient in cosmetic products. The stereoisomers need to be chromatographically isolated from each other in order to assay their activities.

In general, users have to pay for higher yield with lower purity, or vice versa for the purification of (+/- )-α-Tocopherol at standard conditions. However, a baseline separation can be achieved via the elongation of the separation length by peak recycling after three repetition cycles (Figure 2, black). Therefore, fractionation can be performed without compromising the purity or yield.

Figure 2. Comparison of the separations of (+/- )-α-Tocopherol with more (5 µm, red) and less expensive column material (black) with the help of peak recycling.

Conclusion

The separation of the α-Tocopherol isomers can be enhanced through peak recycling, as shown in Figure 2, black. Both purity and yield are similar to the separation with more expensive column material (Figure 2, red).

A standard HPLC system can be easily altered for the implementation of peak recycling. KNAUER HPLC systems have a modular architecture that makes them suitable for the implementation and optimization of these techniques. Different components like the multi-position valve, for changing between the recycling and fractionation mode, can be easily incorporated into the system.

This information has been sourced, reviewed and adapted from materials provided by KNAUER Wissenschaftliche Geräte GmbH.

For more information on this source, please visit KNAUER Wissenschaftliche Geräte GmbH.