Traditionally, the form of highly sloped surfaces has been challenging application for optical profilers using coherence scanning interferometry (CSI). Highly sloped surfaces exist in virtually all industries, such as optical micro-lenses, machined cones and brightness enhancing structures.

Advances in signal detection and processing available on ZYGO’s CSI-based profilers running Mx™ software significantly enhance the capability to obtain valid topography data from highly sloped surfaces.

Theoretical Limits

The theoretical limit for a given microscope objective’s slope capability is based on the numerical aperture (NA) of the lens:

arcsin(NA) = maximum angular acceptance

Typically, a high magnification lens is also a high NA lens. The dependence of the slope limitation on NA is key, as it indicates that high magnification alone is not enough to obtain the highest possible slope resolution.

For instance, a 100x objective lens with a 0.7 NA would have a maximum slope acceptance of 44 degrees. An 0.85 NA objective lens with the same 100x magnification has a maximum slope acceptance of 58 degrees, an improvement of over 30%.

The formula offers a maximum theoretical acceptance angle for a specular test surface - a level that is quite difficult to achieve in practice. When the surface slope is increased and approaches the theoretical limit, there is a weakening of the strength of the light returning into the interferometer.

This produces a low contrast interference signal, which is sometimes barely distinguishable from the background illumination from the interferometer reference surface. The weak nature of this signal is a primary reason for CSI profilers facing difficulty in measuring highly sloped specular surfaces.

The theoretical limit can be surpassed by more than 50% in some cases of non-specular surfaces , due to the scattering structure of the surface. The 100x 0.85 NA lens mentioned earlier allows measuring angles as high as 87 degrees on a machined surface on the Nexview™ profiler.

In Practice on a Smooth Surface

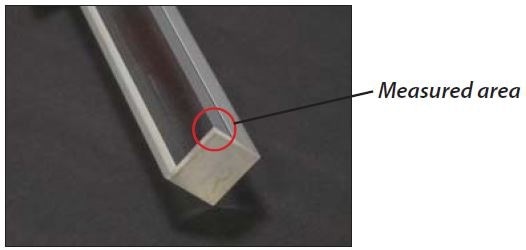

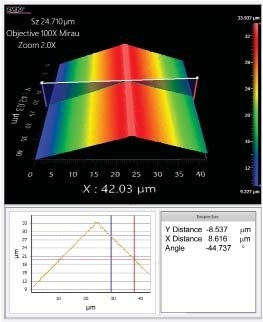

A rectangular glass rod with extremely sharp 90 degree corners was used as a test piece for the example measurements. Placing the rod in a V-block presents the edge of one corner to the system so that each face is at 45 degrees with respect to the reference surface in the interferometer. Using the 100x 0.85 NA objective lens, the NewView™ 8000 profiler running Mx™ software can measure this surface without any difficulty in approximately 15 seconds (Figure 1 and Figure 2).

Figure 1. Quartz rod with near perfect 90° corners.

Figure 2. 45° slope measured on the Nexview™.

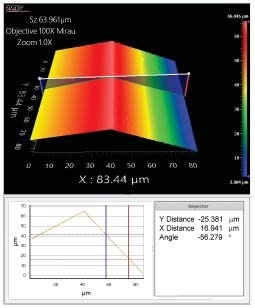

Rotating the V-block by 10 degrees presents the corner so that one surface is inclined away at a slope of 55 degrees, approaching the theoretical limit of 58 degrees determined earlier. The signal strength of the interference pattern is weakened to such an extent that a measurement employing typical settings is not able to detect the surface. However, profilers running the Mx™ software can use the “Dynamic Noise Reduction” technique to reduce the measurement speed and to decrease signal noise so that the weak signal can be detected.

A reduction factor of 6x was used for this measurement and the surface was measured in 350 seconds (Figure 3). The surface can also be detected using smaller noise reduction factors, but this can result in more missing data.

The correct level of dynamic noise reduction is a tradeoff between data density and measurement throughput. If more detailed structure information is required, a higher noise reduction factor can be chosen to maximize the surface.

Figure 3. Quartz rod tilted 10° to present one surface at 56°.

In Practice on a Rough Surface

When measuring a rough surface that scatters light, it is possible to profile substantially higher surface angles than the theoretical specular limit would suggest.

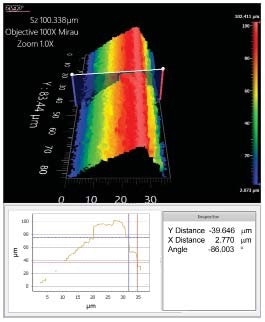

One example is that of the edge of a commercial razor blade. The blade has a surface slope of approximately 60 degrees, however it has a very distinct structure. Like the example of the glass rod, the surface can be tilted further away using a rotation fixture.

This is shown on a Nexview™ profiler with the blade rotated so that the surface is presented with a slope of 86 degrees. The result of this measurement is shown in Figure 4. The measurement was done in 133 seconds using a 100x 0.85 NA lens and 3x Dynamic Noise Reduction.

Figure 4. Commercial razor blade measured on edge shows a measurable surface slope of 86°.

Conclusion and Next Steps

The algorithmic advances and measurement techniques in ZYGO’s CSI profilers running Mx™ software provides significant improvements in measuring steep slopes.

Overview of ZYGO Nexview™ NX2 Non-Contact Optical Profiling System

In most cases, the measurement capability is near to the theoretical limit, and on rough surfaces it is possible for the limit to be surpassed. Due to the variation in the many types of surfaces, ZYGO specifies profilers that deliver more conservative performance than seen in the examples illustrated above.

These new tools are exceptionally powerful for applications that require high slope metrology for form and angle measurements. The tools can provide far more quantitative metrology data in a shorter time period with no damage to parts , compared to competitive non-interferometric methodologies.

A free application evaluation is recommended by ZYGO to check whether such improvements will solve their specific slope measurement challenges. ZYGO profiler applications engineers can be contacted for an evaluation or additional information.

This information has been sourced, reviewed and adapted from materials provided by Zygo Corporation.

For more information on this source, please visit Zygo Corporation.