Pole coils that are used in the synchronous generators of hydro power plants for instance, need to be brazed with high precision. An automatic brazing system from eldec integrated with eldec's Custom Line MFG 75 generator ensures efficient processes.

Precise Induction Brazing

Synchronous generators are the core of a number of power plants. They are used for electricity production. Pole coils, in turn, are a vital component found in all synchronous hydro generators. They are inserted or wound directly onto each pole.

Keeping this in mind, it is evident why the brazing of pole coils is a challenging process. The component has to be precisely placed and fixed in place prior to brazing. Finally, the brazing site is then pressed to stop protrusions around the brazing area.

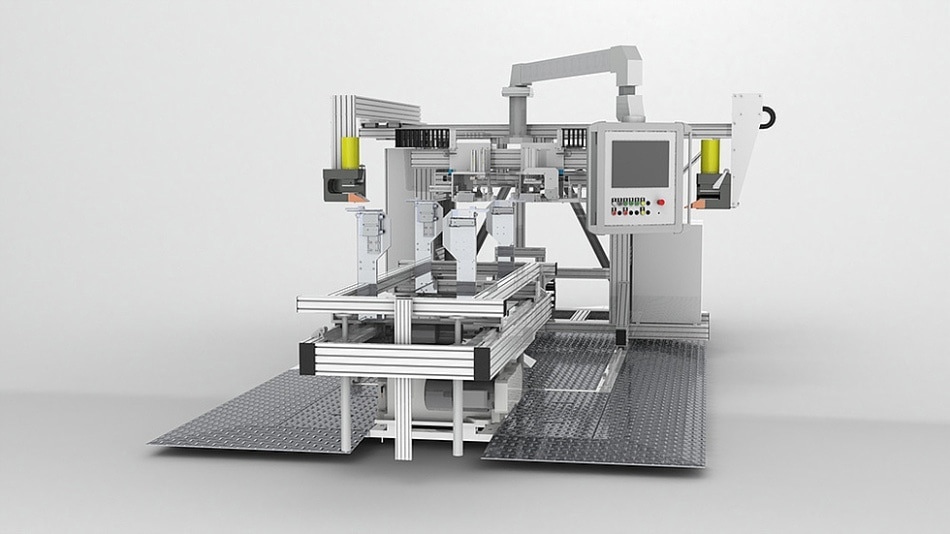

Eldec’s induction experts have developed a brazing system for the manufacture of pole coils that performs the challenging brazing work completely automatically. eldec’s Custom Line MFG75 medium-frequency generator is used as the energy source. This advanced induction generator supplies the required power without any delay, allowing brazing to start immediately. As a result, users stand to benefit from a fast, precise application of heat – which eventually means unmatched brazing quality.

Pole coils have to be brazed with high precision. An automatic brazing system from eldec combined with eldec's Custom Line MFG 75 generator guarantees efficient processes.

The induction experts at eldec have developed a brazing system for the production of pole coils that carries out the demanding brazing work fully automatically.

Brazing Pole Coils

Technical Data

- Pole coil inside length: 600 to 4000 mm

- Pole coil inside width: 150 to 800 mm

- Maximum copper cross section: 15 x 150 mm

- Minimum copper cross section: 3 x 20 mm

- Maximum pole coil height: 300 mm

- Maximum pole coil weight: 2000 kg

Benefits

- High repeatability

- Exceptional brazing quality

- Low energy consumption

- Precise application of heat

Relevant Generators

This information has been sourced, reviewed and adapted from materials provided by Eldec Induction USA, Inc.

For more information on this source, please visit Eldec Induction USA, Inc.