Paul Dempster, Director of Sales and Marketing at Toshiba Imaging Systems Division, talks to AZoM about the inspiration, challenges and applications of Toshiba's newest, ultra-small IK-CT2 Chip-on-Tip Camera.

Toshiba Imaging Systems Division is known for its HD and Ultra HD 4K 3-Chip Technology Video Cameras. What features of these cameras have set Toshiba Imaging apart from its competitors?

There are only a handful of companies in the world that have the capabilities to manufacture 3-chip technology video cameras. Assembly is a key factor, but just as important is the back-end digital image processing which is able to get the most out of the three sensors. Our focus on 1/3” format sensors allows us to design high performance camera blocks that achieve imaging performance equivalent to much larger-sized cameras, incorporating a single image sensor. This is an advantage for surgical and health-tech applications where small form factor is crucial, yet imaging performance needs to be as good as possible.

Toshiba Imaging’s newest technological development is the Chip-on-Tip (COT) video camera. How did the 3-Chip technology lead to the development of Chip-on-Tip technology?

Our camera development is customer-driven and we have developed several distal-tip or chip-on tip technology cameras in the past. These previous camera models were CCD-based solutions and the cost was quite high. We were challenged to develop a small format CMOS-based product for a medical imaging application where we could leverage our manufacturing expertise, image processing, and medical imaging experience. Our 3-chip technology didn’t drive our COT development, but our heritage in medical imaging and digital signal processing helped us to achieve an exceptional result in our latest COT development.

How does this new technology work differently from the current 3-Chip Technology?

In our 3-chip product we need to carefully align three, high-mega-pixel sensors so there is a critical assembly element, as well as the digital image processing, to take advantage of the three sensors. In the COT system, the camera is achieving the best possible performance through an incredibly small sensor and package that fits inside a 1.0 mm diameter hole. Assembly and optics alignment are especially critical; coupled with our image processing, they combine to get the most out of a 220 x 220 pixel sensor, which is quite an achievement. While the final image result is significantly less than the overall resolution of an UltraHD 4K camera, when the COT camera is used in the types of up-close imaging applications that it was intended for, the image quality is equally amazing.

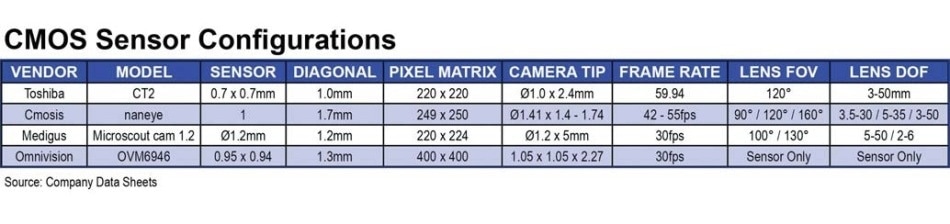

Comparison chart showing 5 COT vendors and specifications from their respective company data sheets. (Image Credits: Toshiba Imaging)

How does this new technology work differently from other imaging systems such as a fiberscope?

As the name implies, chip-on-tip places the imaging sensor directly at the distal tip of the device, so the optics and sensor are located at the tip. In a fiberscope, a bundle of glass or plastic optical fibers are grouped together, transmitting light which can be viewed at the proximal end using the observer’s eyes or by attaching a video camera. In a fiberscope, some of the light fibers could be dedicated to transmitting light for illumination and others used for transmission of the reflected image back. Fiberscopes can be made in extremely small diameters of less than 0.5 mm, however, the resolution and field of view for these ultra-small scopes is proportionately small as well, perhaps as few as 3,000 fibers. In a fiberscope with a diameter of 1.0 mm, the same relative size as the CT2 would typically have a bundle of approximately 10,000 fibers. This is compared to 48,400 pixels of the CT2. In addition, in a fiberscope, the edges of each fiber can be seen, sometimes producing the effect of looking through a window screen where the outlines of the screen can be seen against the image.

Chip On Tip Imaging Technology

With COT, there are no lines around the edges of the pixels so the images appear more clearly and the resolution is generally improved. Fiberscopes also can break down over time with bending of the instrument, glass fibers can break which disrupts the transmission of light, and as enough fibers become damaged, image clarity and sensitivity will deteriorate. The impact of fiber breaking does not occur when using COT technology. It is possible to add a high resolution video camera to the proximal end of a fiberscope which may facilitate display on a monitor or recording of the images, but the outlines of the fibers will likely be visible and the overall resolution of the scope will not be improved and remains limited by the resolution of the fibers.

How does Toshiba’s IK-CT2 Chip-on-Tip Camera differ from other COT video cameras on the market today?

Toshiba’s CT2 incorporates a very small 0.7 mm x 0.7 mm CMOS sensor and is among the smallest sensors available today. The CT2 utilizes a back-side illumination (BSI) CMOS sensor design, resulting in improved light sensitivity. It also operates at 59.94 Hz which is considered full motion video resulting in very smooth imaging without smearing or tearing. The 220 x 220 pixel matrix of the CT2 is higher than earlier small sensor attempts, and coupled with its multi-element glass lens and image processing, results in an excellent image. It is the cumulative effect of all of the design elements resulting in exceptional resolution, vibrant colors, remarkable sensitivity, and low noise within an incredibly small package. The entire tip assembly will fit within a 1.0 mm diameter hole and the length of the rigid tip is only 2.3 mm long, so it can support design of highly specialized instruments, miniaturized surgical, or industrial inspection devices.

Toshiba Imaging’s IK-CT2 is an ultra-small COT video camera system with a 0.7 x 0.7 mm back-side illuminated CMOS sensor featuring 220 x 220 pixel resolution. Shown with LED lighting option. (Image Credits: Toshiba Imaging)

In contrast, most COT imaging sensors have been 1 mm x 1 mm or larger or have been based on CCD technology. CCD sensors are typically higher in cost and require more support electronics to control them, resulting in fewer available options. CMOS has the advantage of lower cost and in many cases an easier integration path for the image processing. The greatest advantage of Toshiba’s CT2 is its incredibly small size fitting within a 1.0 mm opening vs. a 1.4 mm opening required for a 1.0 mm sensor and can be significant when trying to develop ultra-small instruments. In addition, the 60 frame-per-second video output results in blur-free, real-time imaging which is regarded as superior to 30 fps options. There have been a few attempts at introducing imaging sensors smaller than 0.7 mm, however, these earlier sensors had lower pixel density and the image quality was really not great in terms of sensitivity, resolution and noise.

When looking at the IK-CT2 Chip-on-Tip camera, the first thing that stands out is its size. What is its size and resolution?

The IK-CT2 is a 1.0 mm camera which includes a 0.7 mm x 0.7 mm CMOS BSI sensor and multi-element glass lens with separate video processing unit. The video output is VGA with an active video region of 220 x 220.

How has the IK-CT2 small size impacted its resolution? Is it still possible to capture highly detailed images?

Camera design and sensor development is always a balancing act of implementing the largest pixel size possible, which results in improved light sensitivity and reduced noise, vs. the pixel density (the number of pixels on the sensor) which will contribute to image size and resolution. Optics help to manage the capabilities of the camera. In the case of the CT2, the field of view is quite large at 120 degrees, but the depth of field is small at 3 mm to 50 mm. Compared with a typical HD or 4K video camera, the field of view is often less than 60 degrees but the depth of field might be inches to infinity. Because of the optics, the CT2 is intended for close-up applications where the resolution and detail can be maximized. Many applications for COT cameras involve looking within tubular structures which are only 2 mm to 5 mm in diameter and seeing along the sides of the tubes is the most critical element. In this application, the wide-angle view helps to clearly see the sides, and because the camera is very close to the sides, the resolution is within the working focal range of the camera.

Toshiba 3-Chip Professional Cameras

What applications do you see a camera of this size and resolution having in the medical industry?

The CT2 and other cameras of this size allow development of ultra-miniaturized surgical and therapeutic instruments. In some cases it is allowing the development of new instruments supporting innovative medical techniques. In other cases it is allowing the development of improved instruments which provide comparable performance using a smaller configuration. These can be applied to virtually any surgical or therapeutic application including urology, ENT, women’s health, neuro, pulmonary, orthopedic, dental, cardiac, and heart rhythm. It also can be applied to inspection applications such as full lumen inspection of flexible scopes and surgical instruments as part of the sterile processing of medical devices.

Can you give some examples of how Toshiba’s COT video camera would benefit medical imaging tasks?

The CT2 is already supporting applications where the instrument size has been reduced, allowing access to deeper regions of the human anatomy than previously. In other applications a fiberscope-based instrument has been used and the image quality is substantially improved through the implementation of COT technology based on the CT2.

What are some of the new industrial endoscopic applications that might emerge from COT technology?

On the industrial front, fiberscope-based borescopes have been widely used. The COT technology will allow development of alternative solutions to fiberscopes, offering the potential for improved resolution, sensitivity, recording, and processing. There are already a number of low cost consumer and professional grade systems for plumbing, construction, and home inspection which are based on COT technology. On the higher end, systems for inspection of machined parts, turbines and process monitoring of various machines are possible.

A doctor holds a lighted probe used in endoscopic procedures. (Image Credits: Toshiba Imaging)

Moving into the future, how do you think this technology will change both the imaging class and the sensor class?

In my opinion, there will likely be development in two directions, including imaging sensors that are smaller in size, and higher pixel counts (approaching HD formats) in a small sensor package. There are always tradeoffs, however. To increase pixel count would require decreasing pixel size which can impact image quality, sensitivity, and noise. It will be a challenging endeavor for sensor manufacturers to optimize smallest size, while retaining the best imaging characteristics. The other critical element will be on the optics side. Today, there are basically three lens technologies available: Conventional glass optics, plastic optics and wafer scale. Each has its advantages and tradeoffs. Wafer scale optics are available today, however, the optical performance is not as good as glass technology lenses. Plastic lenses in this size are possible, but the volume is not quite there to support the tooling expense and the optical performance remains below glass optics. Molded glass improves cost and retains optical quality, but is still likely to be more costly than wafer scale or molded plastic. As these technologies advance, I would expect these to allow new camera formats and achieve cost targets while optimizing image performance. As costs come down, it opens increasing options for single-use devices and the proliferation of incorporating vision into an expanding range of applications in industrial, health-tech, and therapeutics.

Where can our readers find out more about Toshiba Imaging and the IK-CT2 Chip-on-Tip video camera?

www.toshiba.com

About Paul Dempster

Paul Dempster is the director of sales and marketing for Toshiba’s Imaging Systems Division, supporting medical device manufacturers, distributors, and industrial integrators of video technology within the Americas. Paul is experienced in surgical imaging, diagnostic imaging, and the integration of core imaging technologies to develop market-leading products.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.