A turnkey solution for quality control of gasoline by near-infrared spectroscopy (NIRS) is provided by Metrohm. Based on a pre-calibration model and a dedicated spectral database, this solution allows manufacturers of gasoline to lower the cost of their daily routine analysis while making the quality of their product much better.

Gasoline is an extensively used product in daily life. At the end of the production process, several quality parameters need to be determined before it can be sold on the market. These parameters include Anti-Knock Index (AKI), Research Octane Number (RON), Motor Octane Number (MON), olefins, aromatics, benzene or oxygen content and density. These parameters are still frequently determined in the laboratory by time intensive physical and chemical analysis involving intricate sample preparation and sometimes costly equipment.

In contrast, NIRS requires neither chemicals nor sample preparation; it can even be used by non-chemists, and results can be obtained in less than a minute. In addition, with a single measurement, multiple physical and chemical parameters can be determined at the same time. NIRS has become the perfect solution for an increased number of daily QA/QC measurements or continuous process analysis in the petrochemical industry due to the combined benefits of this technology.

Easy-to-Use

- No expertise needed

- Measure at the push of a button

- Turnkey solution

Fast

- Analysis results within one minute

- No sample preparation

- More than 15 minutes time saving compared to reference methods

Cost Minimizing

- Instant results from first day

- No solvents, no reagents

- No waste disposal

Clean

- Minimum impact on environment and health

- Non-destructive, chemical-free method

Turnkey Solution for Gasoline Analysis

The Metrohm solution for gasoline analysis is available with ready-to-use pre-calibration models for the determination of AKI, MON, RON, olefins, aromatics, oxygen or benzene content and density. Because of these pre-calibrations, it is possible to use the Metrohm solution as a starter model with no method development.

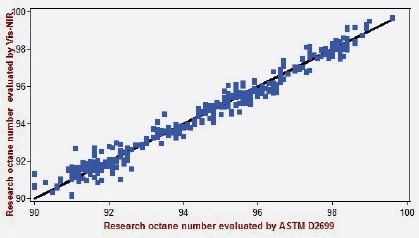

Reliable Results from Day One

The robust pre-calibration model allows accurate and precise determination of several chemical and physical quality parameters of gasoline with exceptional reproducibility.

The performance of the pre-calibration can be enhanced even more, if a smaller calibration range is chosen or if it is augmented with customer specific samples.

Straightforward and Intuitive Operation

Vision Air software controls the Metrohm instruments for Vis-NIR. Vision Air offers two environments customized to users’ requirements: Vision Air Manager enables authorized and experienced users to control data and carry out instrument configurations, while Vision Air routine facilitates secure daily operation by routine users. Measurements can be carried out with two simple clicks for daily quality control of gasoline.

| Parameter |

Range |

SECV |

R2 |

| Anti-Knock Index |

85–94 |

0.45 |

0.948 |

| Aromatics in % |

20–45 |

1.1 |

0.959 |

| Benzene in % |

0.15–0.7 |

0.04 |

0.902 |

| Density in g/cm3 |

0.74–0.76 |

0.0024 |

0.797 |

| MON |

81-88 |

0.53 |

0.889 |

| Olefins in % |

0–25 |

1.3 |

0.909 |

| Oxygen in % |

0.2–2.0 |

0.045 |

0.994 |

| RON |

81–100 |

0.68 |

0.958 |

Customized Service and Support

Metrohm supports users by updating the default pre-calibration on demand with customer specific samples. This in turn enhances the performance of the method and/or extends it to new applications. Such updates are effortlessly performed in the Vision Air Manager Network mode. With Vision Air Network, all instruments within a global customer network can be synchronized at the push of button. Customer specific calibrations can be developed effortlessly for the determination of more quality parameters of gasoline, for example, initial boiling point, naphthalene content, water content and others.

This information has been sourced, reviewed and adapted from materials provided by Metrohm AG.

For more information on this source, please visit Metrohm AG.