Aluminosilicates are used in the catalyst, refractory and building industry while sand is predominantly used as a raw material in the production of many industrial products such as cement and glass. The exact compound concentrations of these materials should be known so that they remain within the tolerances over time and guarantee the constant quality of end products. By knowing the exact concentration of raw materials to use for the creation of final products, waste is avoided and cost savings can be made.

Image Credits: shutterstock.com/nfmik

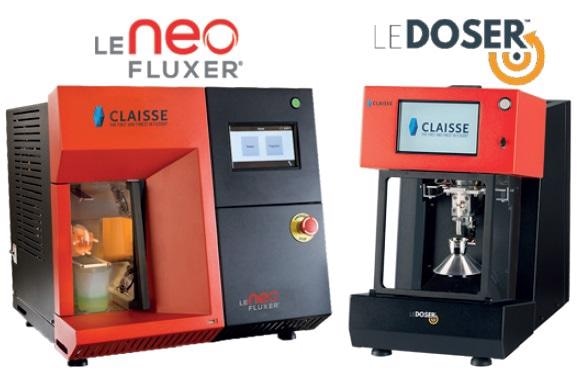

This project aims to establish that sample preparation by borate fusion is the best method to accomplish the highest levels of accuracy and precision for this application. In order to do so, two Claisse® instruments were employed (LeDoser™ and LeNeo® instruments) simultaneously with Claisse consumables (borate flux).

Apparatus and Instrumental Conditions

The samples were ignited using a Fisher Scientific™ Isotemp™ programmable muffle furnace. The aluminosilicate and sand samples were ignited at 950 °C for 60 minutes in a Pt/Au crucible.

Before fusion, the weighing step was performed using an automatic Claisse LeDoser instrument with high precision. Its ratio mode enables an accurate and fast weighing to acquire the exact sample-to-flux ratio needed by the user. Glass disks that are made according to a very precise sample-to-flux ratio offer extremely repeatable sample preparation conditions, thus providing better analytical results.

40 mm lithium borate glass disks were created using an automatic Claisse LeNeo fusion instrument. Its preset fusion programs, exceptional insulation properties and resistance-based electric system enable a uniform heating, thus offering not only repeatable fusion conditions but also a perfect retention of volatile elements. The glass disks were analyzed using a Panalytical 4 kW MagiX PRO sequential WDXRF spectrometer with a 37 mm collimator mask.

Challenge

To obtain very precise and accurate results for major elements in sand and aluminosilicate matrices.

Benefits

- Financial gain

- Constant quality of final products

- High efficiency

- Fast and easy sample preparation for XRF analysis

- Accurate and precise results

Calibration Strategy and Selection of Control Sample

Four (4) CRMs were employed for the calibration of the XRF application; one (1) from the BAS (BCS 313/1) and three (3) from NIST (SRM 76a, SRM 78a and SRM 1413). Two (2) replicates of each CRM were used to make the calibration. The concentration ranges covered in this method are shown in Table 1. In addition, it also provides the certified concentration (dry basis) of the control sample used to evaluate accuracy and precision.

Table 1. Application Concentration Ranges and Control Sample Composition.

| Compounds |

Concentration range (%) |

Control sample (%)

(BCS 348) (dry#) |

| SiO2 |

18.00-100.0 |

51.1 |

| Al2O3 |

0.000-72.00 |

31.6 |

| Fe2O3 |

0.000-1.80 |

1.04 |

| Na2O |

0.000-1.80 |

0.34 |

| K2O |

0.000-4.00 |

2.23 |

| CaO |

0.000-0.800 |

0.17 |

| MgO |

0.000-0.750 |

0.3 |

| TiO2 |

0.000-3.50 |

1.08 |

| P2O5 |

0.000-1.50 |

0.071 |

#Certified Basis

Results

Nine (9) compounds were analyzed as they were of significance in the sample type. Table 2 shows the precision of the method for CRMs BCS 313/1 and NIST 78a. All CRMs were fused in five (5) replicates glass disks. The results are given in concentrations. These samples were selected since they cover the entire calibration range for SiO2 and Al2O3 (high and low concentrations).

Table 2. Precision of the Fusion Method with XRF Analysis.

| Compounds |

BCS 313/1 (standard) |

NIST SRM 78a (standard) |

| Concentration (%) |

SD (%) |

Concentration (%) |

SD (%) |

| SiO2 |

99.78 |

0.06 |

19.4 |

0.01 |

| Al2O3 |

0.036 |

0.002 |

71.7 |

0.02 |

| Fe2O3 |

0.012 |

0.001 |

1.2 |

0.001 |

| Na2O |

0.003 |

0.001 |

0.078 |

0.002 |

| K2O |

0.005 |

0.001 |

1.22 |

0.002 |

| CaO |

0.006 |

0.001 |

0.11 |

0.001 |

| MgO |

0.0013 |

0.001 |

0.7 |

0.002 |

| TiO2 |

0.017 |

0.001 |

3.22 |

0.003 |

| P2O5 |

NA |

NA |

1.3 |

0.004 |

The accuracy and precision of the method for the control sample is shown in Table 3. The accuracy result obtained is compared to the certified value for CRM BCS 348. The average value of five (5) glass disks was subtracted from the certified value to achieve accuracy.

Table 3. Accuracy of the Fusion Method with XRF Analysis.

| |

SiO2 |

Al2O3 |

Fe2O3 |

Na2O |

K2O |

CaO |

MgO |

TiO2 |

P2O5 |

| Glass disk |

(%) |

(%) |

(%) |

(%) |

(%) |

(%) |

(%) |

(%) |

(%) |

| BCS 348-1 |

51.13 |

31.56 |

1.043 |

0.340 |

2.231 |

0.168 |

0.310 |

1.087 |

0.073 |

| BCS 348-2 |

51.13 |

31.58 |

1.043 |

0.342 |

2.231 |

0.165 |

0.306 |

1.081 |

0.072 |

| BCS 348-3 |

51.07 |

31.53 |

1.044 |

0.344 |

2.223 |

0.165 |

0.305 |

1.078 |

0.073 |

| BCS 348-4 |

51.14 |

31.56 |

1.042 |

0.341 |

2.230 |

0.165 |

0.304 |

1.078 |

0.075 |

| BCS 348-5 |

51.06 |

31.54 |

1.042 |

0.343 |

2.229 |

0.165 |

0.308 |

1.083 |

0.074 |

| Average (%) |

51.10 |

31.55 |

1.043 |

0.342 |

2.228 |

0.165 |

0.307 |

1.081 |

0.074 |

| SD (%) |

0.04 |

0.02 |

0.001 |

0.002 |

0.003 |

0.001 |

0.002 |

0.004 |

0.001 |

| RSD |

0.07% |

0.06% |

0.10% |

0.50% |

0.15% |

0.72% |

0.80% |

0.35% |

1.37% |

| *BCS 348 |

51.1 |

31.6 |

1.04 |

0.34 |

2.23 |

0.17 |

0.3 |

1.08 |

0.071 |

| Accuracy (%) |

0.00 |

-0.05 |

0.003 |

0.002 |

-0.002 |

-0.005 |

0.007 |

0.001 |

0.003 |

*Certified Values

Conclusion

This was a successful project. From Tables 2 and 3, it can be seen that sample preparation by borate fusion followed by XRF analysis is an effective method for analyzing aluminosilicate and sand samples on a variety of compositions. Overall, the method showed exceptional accuracy and precision for the nine (9) compounds analyzed. This work shows that the use of Claisse LeNeo and LeDoser instruments considerably helps to correctly prepare aluminosilicate and sand samples for the analysis with a XRF spectrometer.

As borate fusion is efficient, easy and fast, it is a good alternative when compared to other sample preparation techniques used in the laboratory. The broad range of high-quality products and services from Claisse will save users time, money and effort in their sample preparation.

This information has been sourced, reviewed and adapted from materials provided by Claisse.

For more information on this source, please visit Claisse.