A brittle material is prone to cracks and fractures, with the cracks often showing extension from either end. The property of resisting crack growth is called fracture toughness (Kc). Thus a material which has a higher fracture toughness is less likely to develop crack growth (flaw tolerance). This important material property is important when engineering load-bearing structures within load limits. Brittle materials can thus be tested using indentation testing which results in stable cracks extending out of the residual impression, and these cracks can be used to yield an approximate Kc value in the absence of applicability of conventional thin films and surfaces testing.

Indentation of Schott BK7

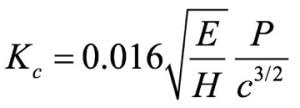

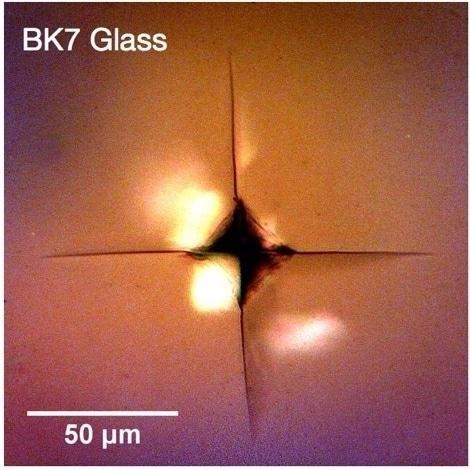

In the experiment being described here, a borosilicate glass, Schott BK7, was subjected to indentation with a Vickers tip mounted on an iMicro nanoindenter from Nanomechanics, Inc. This was aimed at producing a crack by which fracture toughness could be assessed using this equation:

| BK7 Indentation Cracking Measurements |

| Nanoindentation Elastic Modulus, E |

82 GPa |

| Nanoindentation Hardness, H |

7.7 GPa |

| P/c3/2 |

18.4 MPa m1/2 |

| Fracture toughness, Kc |

0.96 MPa m1/2 |

Figure 1. Indentation cracking in Schott BK7 borosilicate

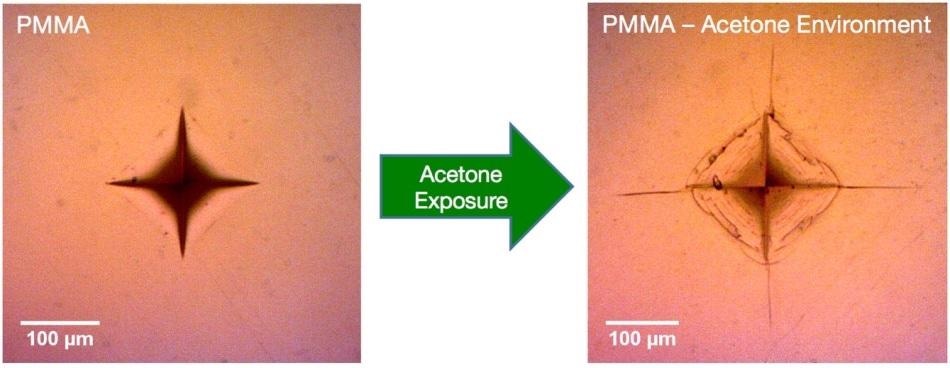

Indentation of Plexiglas

As another practical example, Plexiglas or PMMA is a shatterproof transparent plastic, and does not crack on indentation when a sample is tested in factory-fresh condition, unlike the above sample of Schott BK7. However, the behavior of materials varies following exposure to a range of environmental conditions, which may include heating and cooling. The induced changes in mechanical properties may be astonishingly wide. These changes may be predicted using indentation tests. For instance, following indentation in an acetone medium, Plexiglas cracking was observed to start and to spread from the corners of the indentation. This phenomenon is crack extension with the assistance of an environmental factor (environmentally assisted crack growth), also termed stress-corrosion cracking.

Figure 2. Vickers indentations in PMMA, as-formed vs. acetone environment.

This information has been sourced, reviewed and adapted from materials provided by Nanomechanics, Inc., a KLA-Tencor company.

For more information on this source, please visit KLA.