Almost all materials corrode over time. When determining if a coating will withstand corrosion it is more helpful to test the surface to obtain useful data rather than subjecting it to such extreme conditions that barely any material will survive it.

For example, if you are interested in determining if a material will withstand salt spray at ambient conditions, subjecting the material to hydrochloric acid at 150 °C will not provide any useful results as the acid is different from salt water. Either the coating will fail too soon, or even if you find a material that withstands the test, it may be prohibitively expensive for use in the application. So, it’s really about finding the right test rather than the most extreme test. It is best to understand the tests and not believe all the vendor-supplied corrosion data. Here is a suggested list of steps to follow.

Check the Vendor Data

Check if you can associate the vendor-supplied data to your application

Make sure the data is actual experimental data and not standard data from a textbook.

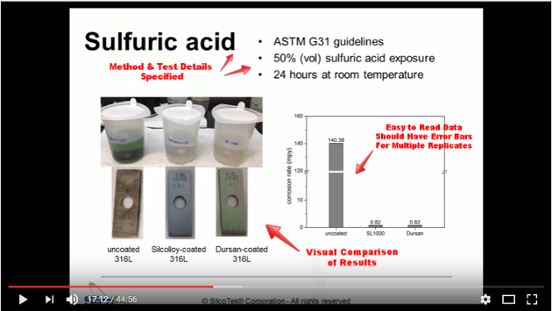

Different industries use different tests. For example in the oil and gas industry, sulfuric acid exposure data is used, and in semiconductors HBr is used. It is better to use material from a company that has the relevant test data than a material that has never been tested. Another point to check is if several materials have been compared.

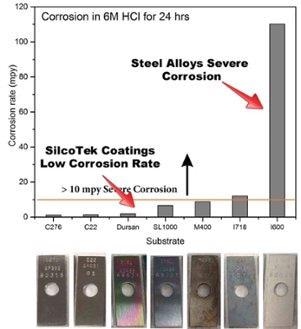

The following data compares corrosion data according to ASTM G31 for many materials and the coating Dursan?. It is 24-hour immersion in ambient conditions in hydrochloric acid. Looking and comparing test coupons after testing can give a good idea of the coating performance.

The data you get from the vendor may not be exactly what you are looking for. The temperature may be different or the solution used may be different. So, it’s best to take a closer look at the data and specify the exact test conditions you are looking for. Accelerated testing can significantly reduce the total test time when designed properly.

The source of the vendor data is also important. Data from an approved lab according to a standard method is best. Sometimes the data can be for a bulk material from standard texts and not that of the coating Dursan®. A bulk material will work differently than a thin coating. For example, bulk silicon will not corrode in acid, but that does not mean a silicon coating on stainless steel will perform as well. The quality of the coating, the number of pinholes, adhesion, and coating thickness will all affect coating durability.

Digging Deeper to do Your Homework

Check if your industry trade organization has any test guidelines

Check materials and approved test methods from NACE, which can be bought from ASTM.

It is important to choose approved test methods, as they will ensure coatings are compared properly and under the same test conditions. Technical organizations like NACE can be very helpful in providing these methods. Rarely do data from different vendors match, so it is crucial to ensure the tests are performed under the same conditions. Specifying a NACE or ASTM coating test method that have complete test specs will guarantee the results you get are what you need.

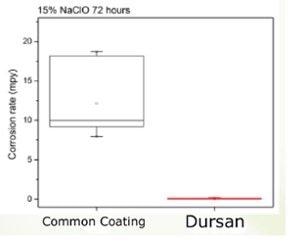

Another point to take into account in vendor data is the number of samples. Since corrosion testing is expensive, reducing the number of samples is attractive. But, testing at least 3 to 5 samples ensures the coating performance variability is tested. As an example, in a 72-hour bleach immersion test with 5 samples, the Dursan samples had a narrow range in variability, while the competing sample showed a larger performance variability.

Read and Understand the NACE or ASTM Method, then Go to a Lab

Working with an approved testing lab can ensure the data you get is reliable. It’s best to specify the test you want the lab to perform rather than asking them to suggest something, which will be a lot of tests and very expensive. The tests suggested may be too aggressive or, not aggressive enough, and may not fit what you need exactly. Knowing your application, learning about the tests, and going to the lab prepared will ensure you get good data.

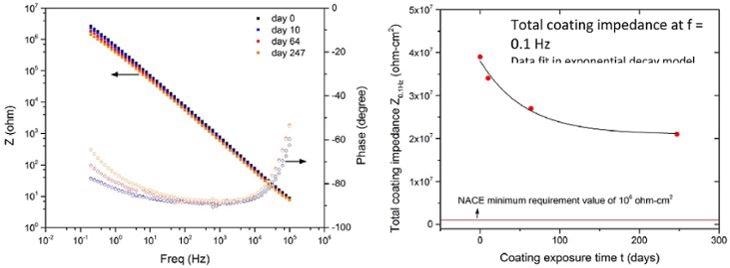

Use Silcotek’s Lab

Although an independent lab is best for corrosion testing, some of SilcoTek’s coating customers have asked them to some corrosion testing too. SilcoTek has some capability to do the ASTM immersion test and the salt spray test, which can be useful for initial coating evaluation. For example, an impedance test according to NACE can be useful for determining coating stability and pinhole rate. The 247 day salt spray testing is one such example. Using SilcoTek’s lab can be a fast and inexpensive way of getting data, but it is best to be prepared before testing.

This information has been sourced, reviewed and adapted from materials provided by SilcoTek.

For more information on this source, please visit SilcoTek.