Temperature programmed reduction (TPR) is an analytical technique that examines the surface chemistry of metal oxides under varying thermal conditions, an important factor in catalysis studies. TPR-enabled mass spectrometry equipment can acquire quantitative and qualitative data relating to the reduction of gas mixtures that are made to flow over metallic samples. This process is integral to catalyst investigation as it provides accurate insights into gas reduction rates in the presence of metal surfaces, informing conclusions on catalyst reproducibility and supporting quality control of existing catalytic substances by setting benchmarks or reduction profiles that ideal manufactured catalysts should adhere to.

How is TPR Performed?

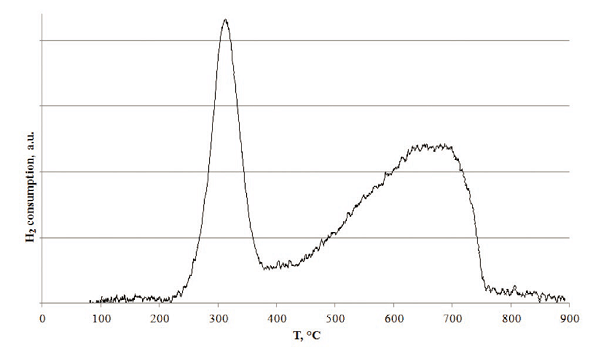

In a typical Temperature Programmed Reduction experiment, a metal oxide such as nickel (NiO) is dispersed upon a surface known as a fixed bed reactor. A reducing flow gas, such as hydrogen (H2) is then pumped into the chamber and moves across the catalyst as the temperature is gradually increased. By increasing the heat linearly, the reduction can be plotted against time. At the outlet a highly-sensitive detector continually analyses the chemical difference in atmospheric concentration, producing an accurate picture of the maximum or peak reduction rate of the catalyst. TPR profiles produced using this method are instrumental in ascertaining a metal oxide’s potential use as commercial or industrial catalytic materials.

Although a powerful technique, the complete picture cannot be acquired just using TPR, so these linear heating experiments are usually performed alongside spectrometric equipment.

TPR Mass Spectrometers

The Hiden Analytical CATLAB-PCS therefore combines both pieces of equipment within a microreactor chamber and a mass spectrometer system. A modular bench-top system, the CATLAB-PCS is extremely versatile with a large range of operating modes that allow multiple experimental methods for catalysis and reaction studies.

It features a sensitive thermocouple in the reactor bed for direct catalyst temperature measurement alongside the linear heating and reduction values collected by the system’s intuitive software together with data acquisition from the mass spectrometer. It has a template-driven software, allowing for precise and automated control of gas composition and flow rates. The standard system can be manually operated or programmed to established templates, with heating rates of up to 1000 °C in increments of 1 – 20 °C.

Allowing the user complete control of precise heating rates and mass spectrometer parameters, the CATLAB-PCS is crucial equipment for any modern catalysis study.

TPR Experiments with Hiden Analytical

Hiden Analytical has over 35 years’ expertise in the design, manufacture, and supply of quadrupole mass spectrometers with their highly customizable, modular designs, they are able to meet any application specification. As they are constantly researching and optimizing their own products they have a thorough understanding of established and emerging laboratory and production processes, and are ever-focused on streamlining those procedures through the application of incredible hardware and software.

They have a wide range of mass spectrometers for TPR studies that may be augmented with additional modules to collect data unique to a certain research area. If you would like any more information about their TPR mass spectrometers, please don’t hesitate to send them a message.

This information has been sourced, reviewed and adapted from materials provided by Hiden Analytical.

For more information on this source, please visit Hiden Analytical.