Rapid analysis of multiple properties can be carried out in a single procedure using FT-NIR technology.

Image Credit: Horiyan/Shutterstock.com

Overview

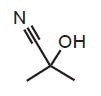

Acetone cyanohydrin (ACH) is an organic compound used as part of the manufacture of methyl methacrylate. This is the monomer of polymethyl methacrylate (PMMA), a transparent plastic which is commonly named acrylic. Three distinct steps are present during the ACH process: reactor, crude, and pure product.

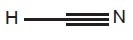

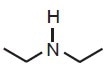

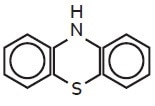

In this study, the possibility of using FT-NIR spectroscopy to provide real-time feedback and optimization during the ACH process was studied. To investigate this, chemical properties in each of the ACH process stages were measured by FT-NIR. The chemical properties measured were ACH, free HCN, and diethyl amine (DEA) in reactor, SO2 and water in crude, and acidity, acetone, phenothiazine and water in pure product.

FT-NIR provides significant advantages as a measurement tool during this process: no sample preparation is required, analysis is fast, numerous properties can be tested in one operation and minimal maintenance is needed.

Acetone cyanohydrin

HCN

Diethylamine

Acetone

Phenothiazine

Application Details

Method

- Detector: InAs, thermoelectrically cooled

- Instrument: ABB MB3600 FT-NIR analyzer

- Resolution: 16 cm-1

- Number of scans: 128

- Sampling technique: vial holder 12 mm

Results

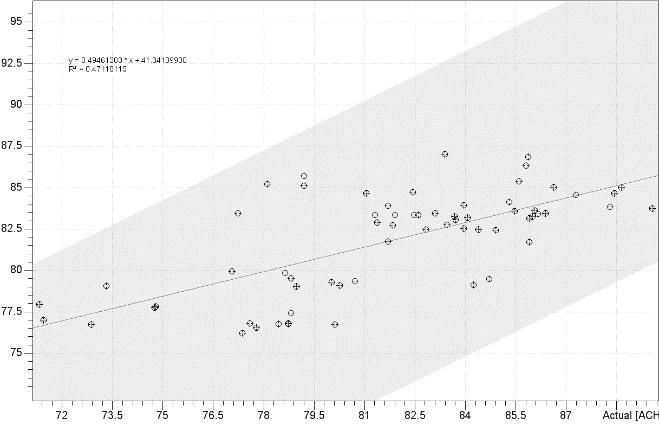

Actual vs predicted for ACH in reactor

FT-NIR calibration performance table

| Property |

Range |

R2 |

Uncertainty

(1*σ ) |

| ACH (reactor) |

71.3 to 89.6% |

0.47 |

3.07 |

| Free HCN (reactor) |

0.03 to 7.07% |

0.73 |

0.77 |

| DEA (reactor) |

0.05 to 0.12% |

0.74 |

0.0077 |

| H2O (crude) |

0.94 to 4.8% |

0.90 |

0.29 |

| SO2 (crude) |

71 to 1097 ppm |

0.81 |

125.5 |

| Acetone (product) |

0.28 to 0.64% |

0.69 |

0.04 |

| H2O (product) |

0.15 to 1.2% |

0.69 |

0.08 |

| Acidity (product) |

0.1 to 0.21% |

0.72 |

0.013 |

MB3600 FT NIR analyzer. Image Credit: ABB Ltd.

Conclusion

The findings presented in this study show that ABB FT-NIR technology can be used to determine free HCN, DEA, ACH, acidity, water, SO2 and acetone during the ACH process. However, measurement of the present samples was insufficient to characterize the process conditions, and the results for each property were not adequately dispersed across the measurement range (e.g. H2O in product).

More representative process samples, spanning the variability of process conditions, could enhance the results. A greater number of signatures and further data related to the chemical properties containing the OH/NH function group (e.g. ACH, DEA or acidity) could be acquired if the full OH first overtone region was covered, for example, using using 5 mm vials or sample cell path lengths.

This information has been sourced, reviewed and adapted from materials provided by ABB Analytical Measurements.

For more information on this source, please visit ABB Analytical Measurements.