The titanium metal can be blended with elements such as molybdenum, aluminum, tin, and vanadium to make alloys that have low density, higher strength, and better corrosion resistance. Due to these properties, titanium alloys are used in aerospace industries, in the military, and for making sporting goods and medical devices. The stringent demands of these applications mean that efforts need to be taken to ensure that the material fulfills the highest quality standards.

Nitrogen and oxygen are used as alloying elements in titanium and are also categorized as alpha stabilizing elements since they promote alpha phase alloys. Interstitial nitrogen and oxygen levels can be used to control the tensile strength of the material; however, their high solubility could lead to undesirable surface embrittlement. Yet, this phenomenon can be controlled, under regulated processing, to produce surface films that enhance wear properties and surface hardness.

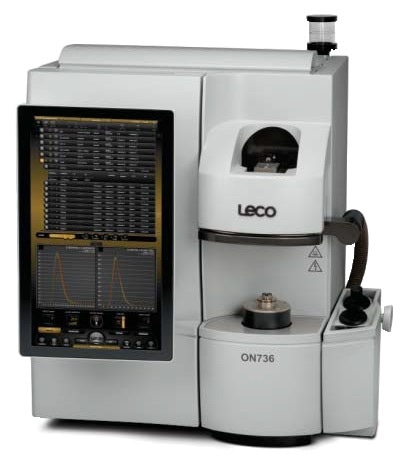

The LECO ON736 is a simultaneous nitrogen and oxygen determinator that is equipped with an inert carrier gas, an electrode furnace, and both thermal and infrared conductivity detection to satisfy the analytical demands of the refractory metal industry. This article is specifically for use with the LECO ON736 series determinator.

Sample Preparation

Optimum results can be obtained only by using a clean and representative sample. Surface contamination of the solid samples should be eliminated before the analysis. It is customary to chemically etch titanium samples to eliminate surface contamination when nitrogen and oxygen are determined. ASTM Method E1409, “Determination of Oxygen and Nitrogen in Titanium and Titanium Alloys by the Inert Gas Fusion Technique”, enables either abrading (filing) or chemical etching of the test specimen. Other refractory metals, such as tantalum, zirconium, rhenium, molybdenum, niobium, and hafnium are usually abraded, rinsed with a solvent (for example, acetone), and dried using warm air.

All traces of the solvent should be carefully eliminated before the analysis. In the case of porous materials (for example, tungsten), solvents should not be used as it can be challenging to eliminate all traces of the solvent by drying. Typically, a solvent, such as acetone, is used for rinsing the chip samples if the material is not porous. Usually, powder samples are analyzed without any additional preparation. For additional details, one can refer to the ASTM methods below.

Method

ASTM E1409, ASTM E1569

Accessories

782-720 graphite crucibles, 782-721 lower electrode tip for 782-720 crucibles without automation; 618-376 lower electrode tip for 782-720 crucibles with automation, 502-344 nickel baskets, 502-822 nickel capsules, 501-073 graphite powder.

Calibration Samples

LRM®, LCRM®, NIST, or other appropriate refractor metal reference materials.

Procedure—Solid Samples

- The instrument has to be prepared as detailed in the operator’s instruction manual.

- The instrument blank should be determined.

- A minimum of three blank replicates must be logged in.

- The Analyze icon on the instrument screen should be pressed. Following a short delay, the slide-block opens.

Note: When automation is used, samples must be placed in the suitable autoloader position prior to starting the analysis sequence. Once the sequence starts, the analysis starts and ends automatically.

- A 502-344 nickel basket has to be placed into the loading head or into the suitable autoloader position.

- When the Analyze icon on the instrument screen is pressed again, the slide-block closes and the lower electrode opens.

- The upper and lower electrodes must be cleaned manually or using an equipped automatic cleaner.

- About 0.05 g of 501-073 graphite powder should be added to a 782-720 graphite crucible.

- It is necessary to place the crucible firmly on the lower electrode tip or the suitable autoloader position.

- When the Analyze icon on the instrument screen is pressed, the lower electrode closes and the analysis sequence starts and ends automatically.

- Steps 2b to 2h should be repeated at least three times.

- To set the blank, the procedure detailed in the operator’s instruction manual should be followed.

- Instrument calibration/drift correction.

- A minimum of three Standard replicates should be logged in.

- About 0.10–0.15 g of a reference material must be weighed, and the mass and sample identification should be entered into the suitable replicate fields.

Note: LECO Reference Materials do not have to be prepared. See preparation statement on the reference material certificate.

- The reference material should be placed into a 502-344 nickel basket.

- The Analyze icon on the instrument screen should be pressed. Following a short delay, the slide-block opens.

Note: When automation is used, it is necessary to place the samples in the suitable autoloader position before the start of the analysis sequence. Once the sequence starts, the analysis starts and ends automatically.

- The nickel basket with the reference material must be placed into the open port at the top of the loading head.

- Upon pressing the Analyze icon on the instrument screen again, the slide-block closes and the lower electrode opens.

- The upper and lower electrodes must be cleaned manually or using an equipped automatic cleaner.

- About 0.05 g of 501-073 Graphite Powder should be added to a 782-720 graphite crucible.

- It is necessary to place the crucible firmly on the lower electrode tip or the suitable autoloader position.

- When the Analyze icon on the instrument screen is pressed, the lower electrode closes and the analysis sequence starts and ends automatically.

- Steps 3b to 3j should be repeated at least three times for each reference material.

- The procedure detailed in the operator’s instruction manual should be followed for calibration/drifting.

- Analyze samples.

- For logging in the sample, the suitable number of replicates should be used.

- About 0.10–0.15 g of a prepared sample should be weighed, and the mass and identification should be entered into the suitable replicate fields.

- The weighed sample must be placed into a 502-344 nickel basket.

- Steps 3d to 3j should be repeated for sample analysis.

Method Parameters

| . |

. |

. |

. |

| General Parameters |

|

|

|

| Sample Introduction |

|

Automated Sample Drop |

|

| Analysis Delay |

|

30 s |

|

| Auto Analyze on Mass Entry |

|

No |

|

| Outgas Before Mass Entry |

|

No |

|

| Wait for User to Load Sample |

|

Yes |

|

| Vacuum On Time |

|

18 s |

|

| Element Parameters |

Oxygen |

|

Nitrogen |

| Integration Delay |

0 s |

|

10 s |

| Starting Baseline |

2 s |

|

2 s |

| Use Comparator |

No |

|

No |

| Integration Time |

35 s |

|

65 s |

| Use Endline |

Yes |

|

Yes |

| Ending Baseline |

2 s |

|

2 s |

| Furnace Parameters |

|

|

|

| Furnace Control Mode |

|

Power |

|

| Outgas Furnace Settings |

|

|

|

| Cycles |

|

2 |

|

| Power Mode |

|

Constant |

|

| Power |

|

5500* W |

|

| Time |

|

20 s |

|

| Cool Time |

|

5 s |

|

| Surface Oxide removal |

|

|

|

| Remove Surface Oxides |

|

No |

|

| Analyze Furnace Settings |

|

|

|

| Step 1 Power Mode |

|

Constant |

|

| Power |

|

4750* W |

|

| Approximate Cycle Time |

|

3.5 minutes |

|

*May vary, depending on line voltage. Level can be adjusted to facilitate recovery and/or reduce crucible burn-through.

Typical Results—Solid Samples*

| Name |

Mass (g) |

Oxygen % |

Nitrogen % |

| 502-880 |

0.1114 |

0.108 |

0.0023 |

| Titanium Pin |

0.1160 |

0.111 |

0.0024 |

| O: 0.110 ± 0.004 % |

0.1178 |

0.110 |

0.0025 |

| N: 0.002 ± 0.001 % |

0.1177 |

0.109 |

0.0024 |

| |

0.1140 |

0.109 |

0.0024 |

| |

Avg = |

0.109 |

0.0024 |

| |

s = |

0.001 |

0.0001 |

| 502-890 |

0.1019 |

0.140 |

0.0020 |

| Zirconium Pin |

0.1194 |

0.139 |

0.0019 |

| O: 0.141 ± 0.005 % |

0.1220 |

0.140 |

0.0022 |

| N: 0.0020 ± 0.0003 % |

0.1167 |

0.140 |

0.0021 |

| |

0.1209 |

0.140 |

0.0021 |

| |

Avg = |

0.140 |

0.0021 |

| |

s = |

0.0004 |

0.0001 |

| Molybdenum Rod |

0.1038 |

0.0113 |

<0.0005 |

| |

0.1038 |

0.0121 |

<0.0005 |

| |

0.1068 |

0.0121 |

<0.0005 |

| |

0.1050 |

0.0115 |

<0.0005 |

| |

0.1128 |

0.0118 |

<0.0005 |

| |

Avg = |

0.0117 |

<0.0005 |

| |

s = |

0.0003 |

- |

| Tantalum Sheet |

0.1236 |

0.0024 |

<0.0005 |

| |

0.1031 |

0.0028 |

<0.0005 |

| |

0.1071 |

0.0021 |

<0.0005 |

| |

0.1140 |

0.0026 |

<0.0005 |

| |

0.1076 |

0.0030 |

<0.0005 |

| |

Avg = |

0.0026 |

<0.0005 |

| |

s = |

0.0004 |

- |

*Note: Results based on a linear force through origin calibration utilizing LECO 502-888 (Lot #0746-37) Titanium LRM @ 0.354% ± 0.008% oxygen and 502-879 (Lot #0572) Titanium LRM @ 0.014% ± 0.002% nitrogen.

Procedure—Powder/Chip Samples

- The instrument should be prepared as detailed in the operator’s instruction manual.

- The instrument blank should be determined.

- At least three Blank replicates should be logged in.

- The Analyze icon on the instrument screen must be pressed. Following a short delay, the slide-block opens.

Note: When automation is used, it is necessary to place the samples in the suitable autoloader position before the start of the analysis sequence. Once the sequence starts, the analysis starts and ends automatically.

- A 502-822 nickel capsule (leave capsule open) should be placed into the loading head.

- When the Analyze icon on the instrument screen is pressed again, the slide-block closes and the lower electrode opens.

- The upper and lower electrodes must be cleaned manually or using an equipped automatic cleaner.

- About 0.05 g of 501-073 graphite powder is added to a 782-720 graphite crucible.

- The crucible should be firmly placed on the lower electrode tip or the suitable autoloader position.

- When the Analyze icon on the instrument screen is pressed, the lower electrode closes and the analysis sequence starts and ends automatically.

- Steps 2b to 2h should be repeated at least three times.

- The blank must be set based on the procedure detailed in the operator’s instruction manual.

- Instrument calibration/drift correction.

- At least three Standard replicates should be logged in.

- About 0.10–0.12 g of a reference material should be weighed, and the mass and sample identification are entered into the appropriate replicate fields.

Note: LECO Reference Materials do not have to be prepared. See preparation statement on the reference material certificate.

- The reference material should be placed into a 502-822 nickel capsule.

- The Analyze icon on the instrument screen should be pressed. Following a short delay, the slide-block opens.

Note: When automation is used, it is necessary to place the samples in the suitable autoloader position before the analysis sequence starts. Once the sequence starts, the analysis starts and ends automatically.

- The nickel capsule with the reference material should be placed into the open port at the top of the slide-block.

- When the Analyze icon on the instrument screen is pressed again, the slide-block closes and the lower electrode opens.

- The upper and lower electrodes should be cleaned manually or using an equipped automatic cleaner.

- About 0.05 g of 501-073 graphite powder is added to a 782-720 graphite crucible.

- The crucible should be firmly placed on the lower electrode tip or the suitable autoloader position.

- When the Analyze icon on the instrument screen is pressed, the lower electrode closes and the analysis sequence starts and ends automatically.

- Steps 3b to 3j should be repeated at least three times for each reference material.

- The procedure detailed in the operator’s instruction manual should be followed for calibration/drifting.

- Analyze samples.

- Suitable number of replicates should be used for logging in the sample.

- About 0.10-0.12 g of a prepared sample should be weighed, and mass and identification are entered into the suitable replicate fields.

- The weighed sample is placed into a 502-822 nickel capsule.

- Steps 3d to 3j should be repeated for sample analysis.

Typical Results—Powder/Chip Samples*

| Name |

Mass (g) |

Oxygen % |

Nitrogen % |

| NIST 360b |

0.1168 |

0.151 |

0.0046 |

| Zirconium Alloy Chips |

0.1177 |

0.150 |

0.0038 |

| |

0.1177 |

0.150 |

0.0036 |

| |

0.1154 |

0.149 |

0.0045 |

| |

0.1140 |

0.145 |

0.0048 |

| |

Avg = |

0.149 |

0.0043 |

| |

s = |

0.002 |

0.0005 |

| Titanium Alloy Powder |

0.1047 |

0.163 |

0.0286 |

| |

0.1131 |

0.163 |

0.0286 |

| |

0.1193 |

0.164 |

0.0288 |

| |

0.1173 |

0.162 |

0.0304 |

| |

0.1124 |

0.161 |

0.0297 |

| |

Avg = |

0.163 |

0.0292 |

| |

s = |

0.001 |

0.0008 |

| Tungsten Chips |

0.1145 |

0.0326 |

<0.0005 |

| |

0.1158 |

0.0316 |

<0.0005 |

| |

0.1157 |

0.0352 |

<0.0005 |

| |

0.1137 |

0.0332 |

<0.0005 |

| |

0.1081 |

0.0359 |

<0.0005 |

| |

Avg = |

0.0337 |

<0.0005 |

| |

s = |

0.0018 |

- |

| Tantalum Powder |

0.1146 |

0.172 |

0.0252 |

| |

0.1168 |

0.175 |

0.0246 |

| |

0.1191 |

0.176 |

0.0249 |

| |

0.1112 |

0.175 |

0.0251 |

| |

0.1140 |

0.173 |

0.0257 |

| |

Avg = |

0.174 |

0.0251 |

| |

s = |

0.001 |

0.0004 |

*Note: Results based on a linear force through origin calibration utilizing LECO 502-888 (Lot #0746-37) Titanium LRM @ 0.354% ± 0.008% oxygen and 502-879 (Lot #0572) Titanium LRM @ 0.014% ± 0.002% nitrogen.

This information has been sourced, reviewed and adapted from materials provided by LECO Corporation.

For more information on this source, please visit LECO Corporation.